You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FM82 Offroad Teardrop Build

- Thread starter FireMedic82

- Start date

FireMedic82

DIYer

Ok, so I think I've decided to mount a propane tank now. The local Camping World has a 25' propane hose. Should I do that, or run metal lines down the frame? Opinions? I know the metal lines would be safer being under the frame, but it would be adding more weight for sure.

Sent from my XT1030 using Tapatalk

Sent from my XT1030 using Tapatalk

VanIsle_Greg

I think I need a bigger truck!

There are a lot of places that will make you custom certified propane hoses to your specifications (length etc). You can run rubber, or you could run copper? Just keep in mind you will want to have the copper or rubber system tested and certified for insurance purposes (and for personal safety reasons). Keep your lines outside the trailer, as in nowhere near/in/through the sleeping area, and where they go into the kitchen area, make sure it is sealed off from the sleeping area and well vented. Of course, a battery operated LPG leak monitor is a good idea, and they are not onerously expensive.

If it were me, I would do copper with the correct stuff for gas, as well as all the right fittings etc. Then run them to a manifold where you can attach custom (or factory) rubber lines to the stove etc. My friend Mike did this setup and his worked out awesome. All personal opinions of course, it is up to you. Stoked to see this moving along.

Greg

If it were me, I would do copper with the correct stuff for gas, as well as all the right fittings etc. Then run them to a manifold where you can attach custom (or factory) rubber lines to the stove etc. My friend Mike did this setup and his worked out awesome. All personal opinions of course, it is up to you. Stoked to see this moving along.

Greg

FireMedic82

DIYer

Thanks Greg! As far as the insurance purpose, State Farm advised me they won't cover is because it's "homemade" pssh. But I'm liking the copper idea a lot. Thanks for all of the info, that pushed me more in the propane tank direction.

Sent from my XT1030 using Tapatalk

Sent from my XT1030 using Tapatalk

FireMedic82

DIYer

Well, mine will definitely be outside the frame, but the ol' trusty wire loom as I call it would probably protect it pretty good. Hmm. I guess the deciding factor will be the cost of that copper pipe. That could be traumatizing..

Sent from my XT1030 using Tapatalk

Sent from my XT1030 using Tapatalk

You can use black pipe for it along the outside of the frame to save on copper. If possible I would run it on the inside wall of the frame, above the axle and as close to the floor as possible. Less chance of it getting drug across a rock or stump. Your doing a great job on this trailer. Have had fun watching it develop.

FireMedic82

DIYer

Thanks skers! I really appreciate it. That's exactly the idea I've got in my head right now. At Camping World I saw a nice, some-what slender tank that would fit the small build nicely. Thank y'all for the input! I'm definitely going to go for it.

Sent from my XT1030 using Tapatalk

Sent from my XT1030 using Tapatalk

Last edited:

matthewp

Combat Truck Monkey

...Less chance of it getting drug across a rock or stump...

Bingo! That's what I was concerned about. I only have a foot or two protected by the wire loom. If you're going anywhere reasonably under the trailer, protect ti, even if it's copper.

FireMedic82

DIYer

FireMedic82

DIYer

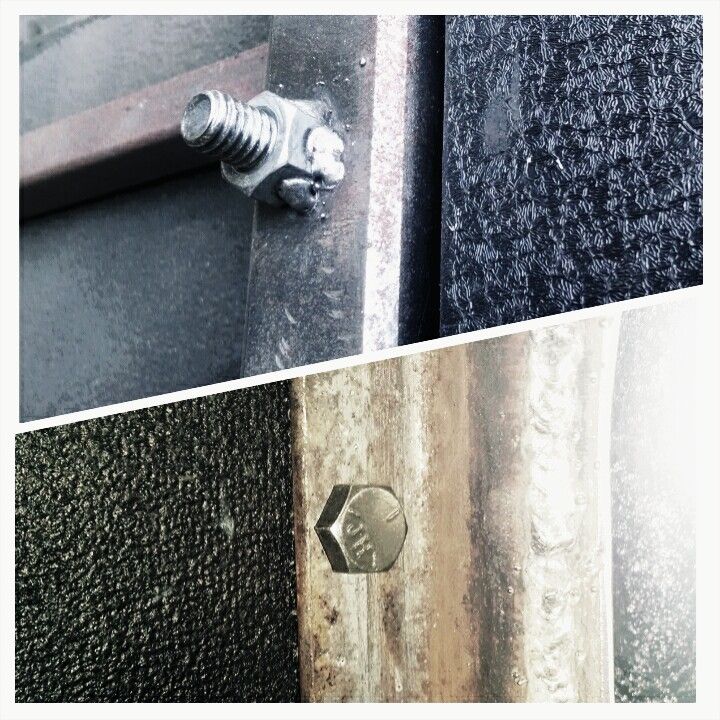

I like that you used steel on the inside of your fender. One of the most dangerous areas for our type of trailer. Picking up a rock and wedging it between a tire and piece of plywood, the plywood is going to lose every time.

I appreciate the effort you are making on this trailer. Few have any idea how much work the steel upper frame is. With steel you need to continuously concern yourself with tongue weight, and continue to counter balance with every item you add.

Also, something I just learned on the Kelly trailer. Do all the basic wiring before you attach any wood, just drape it where you need and leave enough for connections. It makes it a million times easier. With the design you have you should be able to hole saw 3/4 inch holes and run it through the frame where need be. Just be sure to silicone where ever it goes through the trailer frame, to avoid rubbing and shorting down the road. A separate ground wire for every electrical device is warranted, so that if something happens only one goes out, not the whole chain.

On my last trailer I put a sheet of sheet metal on the bottom of the floor and sealed it into angle iron so it had a lip. It will be impossible for water to get through the bottom or do any damage to the plywood.

Like I said, I know how hard you are working to make this right, it is fun to watch someone else take on the project. The rewards in confidence in your trailer will be astronomical.

I appreciate the effort you are making on this trailer. Few have any idea how much work the steel upper frame is. With steel you need to continuously concern yourself with tongue weight, and continue to counter balance with every item you add.

Also, something I just learned on the Kelly trailer. Do all the basic wiring before you attach any wood, just drape it where you need and leave enough for connections. It makes it a million times easier. With the design you have you should be able to hole saw 3/4 inch holes and run it through the frame where need be. Just be sure to silicone where ever it goes through the trailer frame, to avoid rubbing and shorting down the road. A separate ground wire for every electrical device is warranted, so that if something happens only one goes out, not the whole chain.

On my last trailer I put a sheet of sheet metal on the bottom of the floor and sealed it into angle iron so it had a lip. It will be impossible for water to get through the bottom or do any damage to the plywood.

Like I said, I know how hard you are working to make this right, it is fun to watch someone else take on the project. The rewards in confidence in your trailer will be astronomical.

FireMedic82

DIYer

Thanks skers! You're right about the upper frame labor. Just when I think is go time on the siding, I remember things that HAVE to be done before the siding. Time consuming and labor intensive, but I enjoy every minute of it (well, almost lol). What I plan to do for my wiring is to take advantage of the design and strap pvc conduit through every section that I can, so that wire can be fished in and out as needed, and to protect the wiring. As far as the flooring that you mentioned, I'm sure everyone who takes on a build has a regret of some sort. Well, that would be mine lol. I will go about that part differently if I do another build, but it's a newby flaw that I'll just take a little extra time to protect and just push on

Sent from my XT1030 using Tapatalk

Sent from my XT1030 using Tapatalk

FireMedic82

DIYer

FireMedic82

DIYer

Similar threads

- Replies

- 1

- Views

- 916

- Replies

- 2

- Views

- 836

- Replies

- 0

- Views

- 995