The biggest welding project I have ever taken on was my rear bumper. This was supposed to be a family of 4 adventure vehicle...so storage would be at a premium, thus I wanted a swing arm to carry some stuff like jack, spare and water/gas cans.

At first I thought I would just build it off the trailer hitch but in the end I pulled it off and started from scratch.

Bit of a mock up

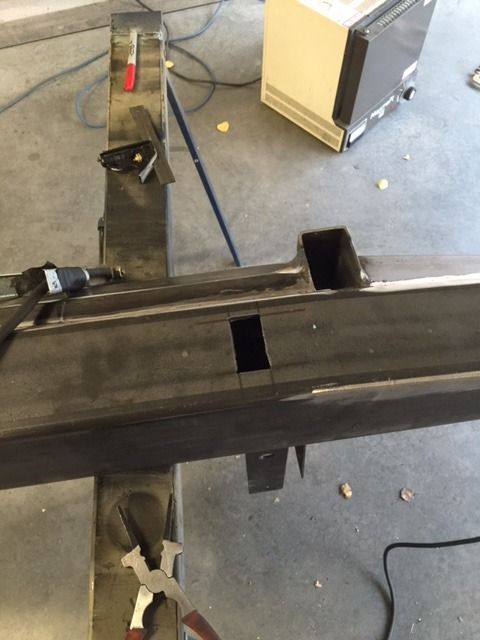

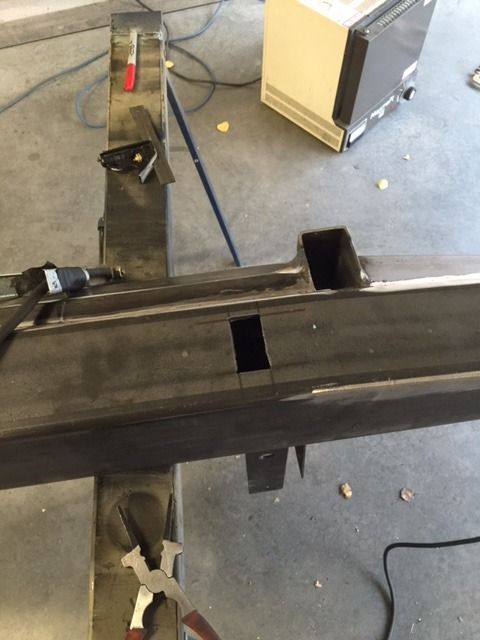

I was gonna base it off a 4" x 6" rectangular tube. I wanted 1/8 wall to save weight but ended up with 3/16"... which is heavy...but strong. I tried to reduce the weight buy cutting out sections with a plasma cutter.

Mounts were made with 3" angle. Because I am a hobby welder all joints were backed up with 2 x 5/8" G8 bolts.

Pinched in the ends to make it look better.

Another mock up

Bent some filler plates to box out the bottom.

Made some mounts for the highlift jack. Made a notch to keep things from sliding off.

Stuck a 2" receiver in the drivers side end....just because.

Pic of my weight saving efforts. I ended up covering the holes with aluminum sheet.

Got the Extreme swing out kit from A-Z Fab. Turned the end down so it pierced both top and bottom of the bumper.

Had to pre heat the spindle to 300 deg because I was worried about penetration with my little welder.

Cut out some holes for the recovery points.

Preheated them and welded them inside and out.

Pretty much done the bumper

Next was the swing arm.

GC