I don't think it is, seems like regular mechanical switches / rheostats for controls. At least the lights respond to them. Have to look at a wiring diagram to be sure.

--

well a qualified success on the transmission temp gauge. It seems to be reading correctly but it took some monkeying around. Further road tests to be conducted.

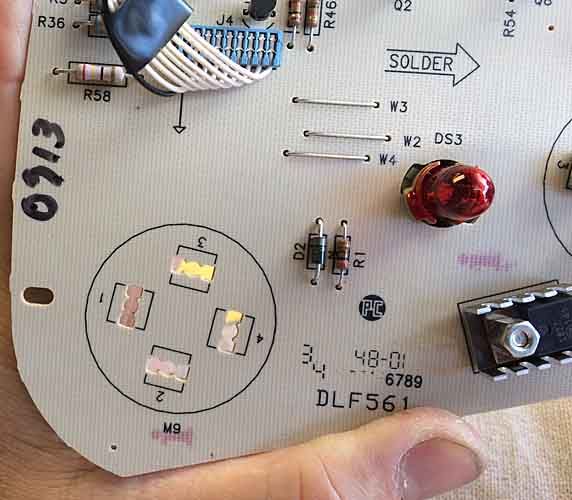

The stepping motors I found were dimensionally the same. They mounted correctly. I took four out of the same panel at the auto scrapyard. Their yellow mounts and 4 pins were all the same, but only one of four was visually identical to my own. THe others have some different details on the back side. But I expect they work the same. I'll try to verify that in the future.

Here's my speedometer stepper on the left, the salvage part on the right, for forward faces:

I pulled me speedo motor, put it in the trans gauge location (a known good motor) and put the scrapyard motor in the speedo location.

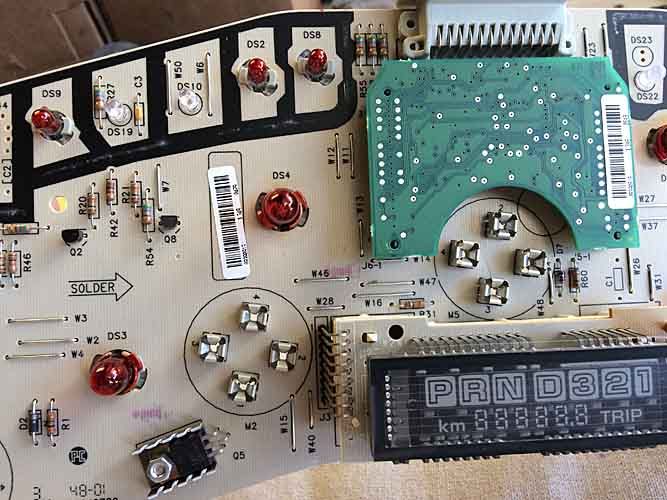

I put the circuit board back in place, over the pins of the motors, hooked it back up in the vehicle and no joy, no apparent activity on the trans stepper. I looked over the back of the circuit board, the pins were penetrating in the same way as the other gauges. But I noticed the trans contacts didn't have the same same soldered protrusions at each end of the contact area.

Pulled the circuit board back off an oh / a-ha. The protrusions on the back were the thru-tabs of the springloaded metal claws that make the actual electrical contact with the pins of the stepper motors.

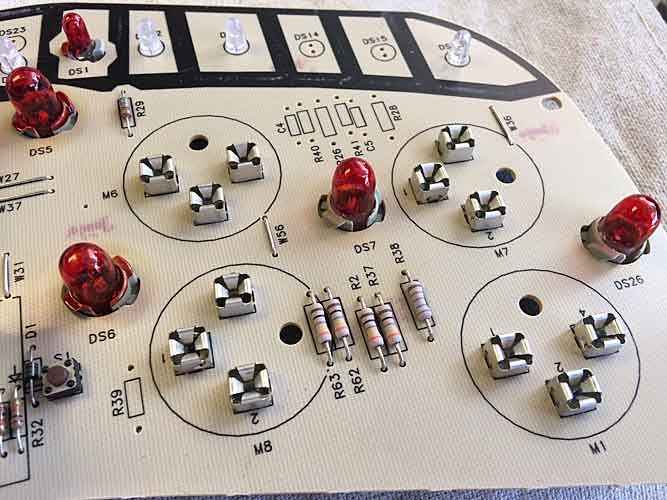

here's what they look like on the front side of the circuit board -

Not also that cluster of four gauges each has only 3 contacts and that two of them are numbered 1,2,3 and two are 1,2,4.

Additionally the Tach and Speedo motors have all four contacts.

And the trans location has none. /sad gameshow music

So I presumed that I needed to make good contact on either 1,2,3 or 1,2,4. At the top of the green board portion of this pic you can see the circuit tracery surrounding the pin penetrations. So I went ahead soldered 1,2,3 put things together again and again no response. Pulled it back apart, heated and sucked the solder off of #3 and instead soldered #4 and seemed to hit pay dirt.

It worked, but response seemed very slow / 'low energy'. Even though it seemed to be accurate. Didn't know if it was a low data sampling rate or a piss-poor soldering joint, so I broke it down one more time and did a more thorough solder connection. And got no livelier response from the gauge.

When it was all said and done, I had the needle set and it was moving as trans temps increased on a neighborhood drive.

So a little more driving and I'll flog it down the highway a bit to see it warm more and cool back down and if it responds I'll call it good.

So at this point I'll say this mod works for GMT800 pickups, '99-02 and SUVs '00-02, And the older stepper motors seem to pre-date '99 as well. I cannot find a part number or source for these older steppers.