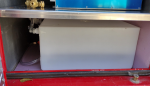

i have owned this fridge / freezer for over 30 months

been in the garage and was the constant reminder of the vision many moons ago

well it finally happened

my new favorite tool

kreg pocket hole jig

worked by myself to get this done as i have deadlines approaching

view from compartment 1 on the passenger side

this will by my electric panel

some 'speed' holes for fans & circulation

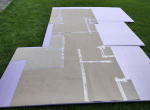

very close to perfect on the reveal and not bad for a club foot engineer who is NOT any sort of woodworker!

like a glove

cut some panels out of galvanized as the original was swollen w/ southern humidity and living in the garage

not sure if i like them painted or raw

may just put the orbital sander on it to obscure the scratches yet to come

so now i can finish the wiring as i wanted it all to be external to the wall cavity whenever possible

there will be 3 x 110V circuits on the driver side and this wiring will be at the floor perimeter

the ac unit AC wiring & most all DC wiring will follow a 'chase' on the passenger side ceiling

plan is for all the switches, dimmers & information systems to be housed in a panel over the door

the space to the right of the freezer will be some 'flange mounted' bins that will be recessed into the wall depth

we have about 3 inches of depth to take advantage of like a medicine cabinet

good place for handy / quick use items

the space to the right of the fridge is utilized for the AC & DC distribution

if you notice the roofing felt nails & plastic tabs in the last picture you will see the potential lighting layout

certainly 3 over the kitchen and the 63" of counter on one circuit w/ a dimmer

1 over the bathroom and 1 over the shower on one circuit w/ a dimmer

the balance is uncertain

LED puck lights are 215 lumens each

im believing that 3 more pair on another circuit w/ dimmer should be more than enough

of course some LED rope light will go under the counter toe kick