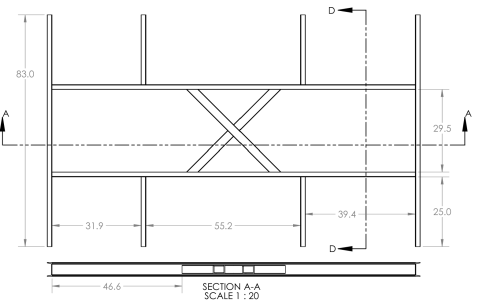

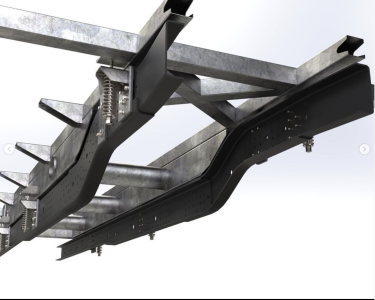

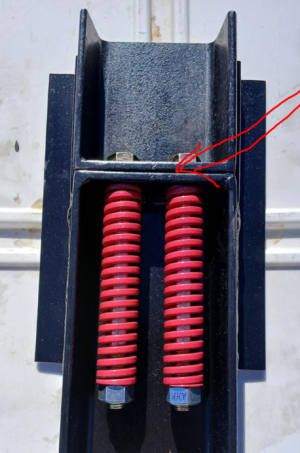

This picture is a frame (seen from the bottom) which is bolted to inner habitat bolt plates (NOT TO THE XPS COMPOSITE FLOOR - kind of like Bison Overland did) . There are 22 grade eight bolts for the attachment over a span of 3700mm x 2200mm.

Note: The wood beams hold the habitat off the ground so we can work underneath it.

Note: The wood beams hold the habitat off the ground so we can work underneath it.

Last edited: