You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Isuzu npr 4wd

- Thread starter gator70

- Start date

Thinking about a 52 inch lightbar on the Isuzu crew cab roof.

I have some space in front of the Habitat over the cab queen bed.

There is space for a slim 100 watt solar panel. (50x15 inches)

You can never have enough solar.

A bracket set could be fabricated for the light bar and solar panel.

I have some space in front of the Habitat over the cab queen bed.

There is space for a slim 100 watt solar panel. (50x15 inches)

You can never have enough solar.

A bracket set could be fabricated for the light bar and solar panel.

I look for any comments!

I'm double checking the truck frame to subframe connection with spring brackets

My total rig weight is about 12,500 lbs (incl habitat)

My habitat weight is 4000lbs dry, 5000lbs loaded with fluids

I plan three spring brackets on each side

Theses below from center to front (red)

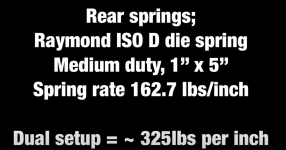

A different one in the rear - (blue)

(blue are weaker and allow more travel than red)

I'm double checking the truck frame to subframe connection with spring brackets

My total rig weight is about 12,500 lbs (incl habitat)

My habitat weight is 4000lbs dry, 5000lbs loaded with fluids

I plan three spring brackets on each side

Theses below from center to front (red)

A different one in the rear - (blue)

(blue are weaker and allow more travel than red)

Last edited:

SkiFreak

Crazy Person

At this point I believe that pretty much everyone knows your views on how every company building composite bodies has got it wrong, and that only you know how to do it right.Most composite habitats have a composite floor. Mine is much, much, much stronger than that.

My experience, after building things for over 50 years, is that a lot of time and money can be wasted over engineering things that don't necessarily need to have the strength of a tank.

If you get a warm and fuzzy feeling thinking that your designs are appropriate, that's fine, as it is your build, but this constant negative commentary on how everyone else gets it wrong is simply ludicrous.

You are not an engineer and most of your knowledge seems to come from the internet, not from actual first hand experience. Some random person saying something online does not necessarily make it factual or relevant.

Engineering is not normally general, it is usually specific to an application. Basically... what works for someone else may be totally inappropriate in another situation.

If you want any credibility in your statements, back them up with engineering facts, not simply your personal opinions or what someone else has said.

At this point I believe that pretty much everyone knows your views on how every company building composite bodies has got it wrong, and that only you know how to do it right.

My experience, after building things for over 50 years, is that a lot of time and money can be wasted over engineering things that don't necessarily need to have the strength of a tank.

If you get a warm and fuzzy feeling thinking that your designs are appropriate, that's fine, as it is your build, but this constant negative commentary on how everyone else gets it wrong is simply ludicrous.

You are not an engineer and most of your knowledge seems to come from the internet, not from actual first hand experience. Some random person saying something online does not necessarily make it factual or relevant.

Engineering is not normally general, it is usually specific to an application. Basically... what works for someone else may be totally inappropriate in another situation.

If you want any credibility in your statements, back them up with engineering facts, not simply your personal opinions or what someone else has said.

You quote a single statement of mine. Fine.

However my habitat floor is not a single sheet of a composite material no matter how thick, nor what wood or fiberglass tube has been bonded inside the laminated structure to reinforce it.

Some other builders think that is fine, even some customers. Sorry that was not my belief. And everyone has a right to an opinion. I respect that.

About my skills, not something I defend as I have extremely high skills in engineering, validated by 45 years of paid employment.

Engineering is a wide field and some specialties are not mine. Just like some specialties are not yours.

Hence some questions I fielded to the community.

Fine.

As far as over engineering, the Germans are known for this. I owned and ran a manufacturing company in southern Germany from 1980 to 1994. With 200 employees, where as we designed products, manufactured products and sold product to 13 countries. In some cases where we designed flat 5mm steel that was formed fairly complex with 400 ton presses. In this case we were advised by engineers from the German automotive industry. We also did large and small injection molded parts as well as custom aluminum extrusions. In one case we replaced steel gears with injected molded carbon fiber reinforced to reduce the production costs while maintaining 90% of the gear teeth strength. Having done all that I would say I have enough engineering real life experiences.

In the case of my subframe and the spring mounts, I did not have background in this. Many folks do not. And in the case of the floor of my habitat I did a one off design that as you say, gave me a warm and fuzzy feeling! It may be over engineered, but that was my choice.

I do learn from others who have done this before, by internet or direct conversations. And I respect everyone's experience.

Last edited:

Peter_n_Margaret

Adventurer

My current rig (in the avatar to the left) has a "composite" floor.

It is glass skins and a polypropylene honeycomb core.

It has done 300,000+km of mostly serious "off road" travel in Australia without the slightest mechanical or engineering concern.

I am currently building a new light weight rig that is very similar to the current one.

The floor will also be composite. Glass skins (1.5mm thick) and a medium density PET foam core.

The reason for the change is because the thermal insulation properties of honeycomb are poor and the PET foam will improve that.

The rest of the box will be similar to the floor but use closed cell polyurethane foam core for lighter weight and better insulation.

Anyone can make something stronger. The price is that weight can quickly get out of control and that leads to an ever-increasing demand to be even stronger and heavier, and around and around you go.

The challenge is to make things only as strong as they need to be.

Having them lighter is always a major benefit.

Cheers,

Peter

OKA196 motorhome

It is glass skins and a polypropylene honeycomb core.

It has done 300,000+km of mostly serious "off road" travel in Australia without the slightest mechanical or engineering concern.

I am currently building a new light weight rig that is very similar to the current one.

The floor will also be composite. Glass skins (1.5mm thick) and a medium density PET foam core.

The reason for the change is because the thermal insulation properties of honeycomb are poor and the PET foam will improve that.

The rest of the box will be similar to the floor but use closed cell polyurethane foam core for lighter weight and better insulation.

Anyone can make something stronger. The price is that weight can quickly get out of control and that leads to an ever-increasing demand to be even stronger and heavier, and around and around you go.

The challenge is to make things only as strong as they need to be.

Having them lighter is always a major benefit.

Cheers,

Peter

OKA196 motorhome

My current rig (in the avatar to the left) has a "composite" floor.

It is glass skins and a polypropylene honeycomb core.

It has done 300,000+km of mostly serious "off road" travel in Australia without the slightest mechanical or engineering concern.

I am currently building a new light weight rig that is very similar to the current one.

The floor will also be composite. Glass skins (1.5mm thick) and a medium density PET foam core.

The reason for the change is because the thermal insulation properties of honeycomb are poor and the PET foam will improve that.

The rest of the box will be similar to the floor but use closed cell polyurethane foam core for lighter weight and better insulation.

Anyone can make something stronger. The price is that weight can quickly get out of control and that leads to an ever-increasing demand to be even stronger and heavier, and around and around you go.

The challenge is to make things only as strong as they need to be.

Having them lighter is always a major benefit.

Cheers,

Peter

OKA196 motorhome

When you set out to build something, you always set goals. From what you said you wanted the best combination of strength and less weight.

When I think about that. It seems I was 2000 lbs underweight. Yet fuel economy is also a reason to keep the weight down.

Since you have more experience than me in composite manufacturing - have you seen delamination? As I have have seen this!

I have noticed how factories worry about delamination - they drill holes or groves in the PET core material to increase the bond. Not all do. And they would not do this if they had not previously witnessed delamination.

Last edited:

Peter_n_Margaret

Adventurer

Only in some poorly manufactured composite.have you seen delamination?

Like most things, there is "composite" and then there is "composite".

Many composite manufacturers take a sheet of foam and glue a sheet of fibreglass (that comes off a roll) to each side.

The good stuff (that I now use exclusively) is made by laying it all up wet-on-wet.

The mob that I buy from have a polished steel table 11m long and 2.8m wide. They start by spraying the table with gel coat, followed by glass and resin, followed by laying out the foam, followed by more glass and resin. Then the whole thing is vacuum bagged.

They then have a CNC router to cut it up with.

Cheers,

Peter

OKA196 motorhome

Peter_n_Margaret

Adventurer

You can not be "underweight" and fuel economy is the least important reason for keeping the weight low.When I think about that. It seems I was 2000 lbs underweight. Yet fuel economy is also a reason to keep the weight down.

Cheers,

Peter

OKA196 motorhome

SkiFreak

Crazy Person

Out of interest... who makes your panels?The good stuff (that I now use exclusively)

Peter_n_Margaret

Adventurer

Out of interest... who makes your panels?

Composite Caravans | Queensland | Vanglass

VLPCaravans - Hi tech composite panel caravans , camper trailers and slide-on campers. Build your own Caravan , camper trailer or slide-ons. Composite fibreglass panels. http://www.vanglassleisureproducts.com.au

www.vanglassrv.com.au

www.vanglassrv.com.au

Terrible web site for someone who makes the best panels. Talk to the owner Shaun.

Cheers,

Peter

OKA196 motorhome

Only in some poorly manufactured composite.

Like most things, there is "composite" and then there is "composite".

Many composite manufacturers take a sheet of foam and glue a sheet of fibreglass (that comes off a roll) to each side.

The good stuff (that I now use exclusively) is made by laying it all up wet-on-wet.

The mob that I buy from have a polished steel table 11m long and 2.8m wide. They start by spraying the table with gel coat, followed by glass and resin, followed by laying out the foam, followed by more glass and resin. Then the whole thing is vacuum bagged.

They then have a CNC router to cut it up with.

Cheers,

Peter

OKA196 motorhome

Many buyers of Composite constructed habitats can never be sure they get the highest quality. Consumers are kept in the dark about the production technics and overall durability.

You are 100% right, about the many grades of Composite panels being sold.

Therefore delamination can be a risk, when you are not sure what the production process was.

The extra effort I did in engineering my floor, was worth the additional $1000 I spent. As I don't worry so much about walls and roof with delamination.

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 7

- Views

- 1K

- Replies

- 28

- Views

- 3K