You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ITTOG's Truck Camper Build (was 6' x 12' Trailer Conversion)

- Thread starter ITTOG

- Start date

ITTOG

Well-known member

Time: 22 hours

Total Time to Date: 254 hours

Rework: 0 hours

Total Rework to Date: 79 hours (not part of time above)

Current Weight: To be weighed, but at least 660 pounds

It sure seems like a lot has happened since my previous post, but not really. Maybe the fact there was 22 hours of work for this update makes it seem like a long time. The work in this update fell in two areas: fiberglass prep and dry layup. The prep took about six hours and the layout was the remaining 16 hours. Luckily, the 16 hours included assistance from my wife, son, and daughter.

I had several activities I needed to complete before fiberglass and can begin. First was the final surface prep. I use expanding foam to fill all of the gaps but it was very porous and does not create a smooth surface. Thus I tried to use the glue I used to bond the foam to the frame. Unfortunately that did not work because the glue dries soft. Thus I use the only other thing I had, wood filler. It worked very well and was solid, the only concern was would it stick to the epoxy. A small test verified that it would. Given this part of the camper will be inside the truck bed I did not spend a lot of time ensuring it was smooth. I I wanted to get the fiberglass and done so I focused on the bigger problem areas. I figure the rest of it I can address after the fact. After, being after I have begun using the camper! In this picture the yellowish-brown color on the foam is the wood filler. Luckily I did not need to use a lot of it.

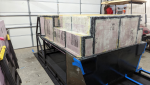

The first layer going on is the front of the camper, bottom, and sides. The interesting item in this picture, or at least to me, here are the tubes you in the corners where the camper stair steps downward. I cut these tubes to help ensure the fiberglass stays in the corner and does not cause delamination between the fiberglass and the foam.

After the surface and fiberglass was prepped I began taping plastic to the camper to protect sections of the camper I do not want epoxy on and the garage floor. I can tell you right now I should have put a lot more on the floor. Some people were a bit lackadaisical on how they held their cups. Thus, we all had epoxy on the bottom of our shoes.

This shows all the supplies we needed. For the hardener, I ended up using the 2094 an extra-long cure. This is because the temperature when we began at 8 AM was about 83° and it warms to about 98° when we finished around 2 PM. Over

Here we go with the first fiberglass panel. Those Tyvek suits make me look fat. Glad that is not my shape!

The girls started helping around 9:30 AM. They both told me later that they did not enjoy fiberglass in. Thus, they will probably never help again. But I sure appreciated their effort.

Continued below...

Total Time to Date: 254 hours

Rework: 0 hours

Total Rework to Date: 79 hours (not part of time above)

Current Weight: To be weighed, but at least 660 pounds

It sure seems like a lot has happened since my previous post, but not really. Maybe the fact there was 22 hours of work for this update makes it seem like a long time. The work in this update fell in two areas: fiberglass prep and dry layup. The prep took about six hours and the layout was the remaining 16 hours. Luckily, the 16 hours included assistance from my wife, son, and daughter.

I had several activities I needed to complete before fiberglass and can begin. First was the final surface prep. I use expanding foam to fill all of the gaps but it was very porous and does not create a smooth surface. Thus I tried to use the glue I used to bond the foam to the frame. Unfortunately that did not work because the glue dries soft. Thus I use the only other thing I had, wood filler. It worked very well and was solid, the only concern was would it stick to the epoxy. A small test verified that it would. Given this part of the camper will be inside the truck bed I did not spend a lot of time ensuring it was smooth. I I wanted to get the fiberglass and done so I focused on the bigger problem areas. I figure the rest of it I can address after the fact. After, being after I have begun using the camper! In this picture the yellowish-brown color on the foam is the wood filler. Luckily I did not need to use a lot of it.

The first layer going on is the front of the camper, bottom, and sides. The interesting item in this picture, or at least to me, here are the tubes you in the corners where the camper stair steps downward. I cut these tubes to help ensure the fiberglass stays in the corner and does not cause delamination between the fiberglass and the foam.

After the surface and fiberglass was prepped I began taping plastic to the camper to protect sections of the camper I do not want epoxy on and the garage floor. I can tell you right now I should have put a lot more on the floor. Some people were a bit lackadaisical on how they held their cups. Thus, we all had epoxy on the bottom of our shoes.

This shows all the supplies we needed. For the hardener, I ended up using the 2094 an extra-long cure. This is because the temperature when we began at 8 AM was about 83° and it warms to about 98° when we finished around 2 PM. Over

Here we go with the first fiberglass panel. Those Tyvek suits make me look fat. Glad that is not my shape!

The girls started helping around 9:30 AM. They both told me later that they did not enjoy fiberglass in. Thus, they will probably never help again. But I sure appreciated their effort.

Continued below...

ITTOG

Well-known member

The result after two layers have been applied. If you noticed the black pigment in the supplies picture you can see here I forgot to use it. Now I have to decide if I want to paint the fiberglass or add another layer of epoxy using the pigment. Anyone have any experience you can share that would help me figure out which direction to go?

I did not sand the wood smooth so there are some places the fiberglass did not stick to it because there were gouges in the wood. But as you can see by far the majority of the fiberglass stuck to the wood. This was more than good enough for what I needed.

Everything I read about fiberglassing vertically required the use of a filler to thicken the epoxy so it would not fall down the wall and pool at the bottom. Therefore, I bought the recommended filler and applied it to the recommended thickness. What a disaster this became! First, it was almost impossible to force the epoxy through the fiberglass. Luckily I used the extra slow hardener for this stuff will harden long before we got the fiberglass to stick to the foam and I was only able to get the fiberglass to stick to the foam by pulling the fiberglass up and applying some epoxy directly to the foam and then laying the fiberglass back down. Luckily we were able to eventually get it to stick. The areas that are less transparent is where the filler was used. After that we did not use anymore filler and the job became easier and quicker.

We did end up having one more problem. The places we used the filler, ended up separating from the phone once we applied the second layer of fiberglass. Thus, when you look at the camper the top part of the step probably has about 40% separation from the foam while the bottom part is about 1% separated. The 1% represents areas I did not get the foam surface perfectly smooth.

I feel the bottom of the camper looks really good.

Here I have removed the excess fiberglass and all of the plastic.

We did have some other smaller issues that will be easy to fix before I finished the fiberglass. This is an area where the fiberglass did not sit down all the way so I cut it off and will apply a patch of fiberglass and epoxy.

In this pic the really white part is where the fiberglass separated from the foam.

Looks like I overlooked the surface law and have a gap between the metal and foam but it is small enough I am not worried about it. For the areas that look like blisters I will most likely send them down and patch the fiberglass. But again, given this will set inside the bed of the truck I don't not want to spend too much time trying to make it perfect. As long as it is waterproof and strong enough to prevent cracks or breakage it will serve its purpose.

Overall I think it turned out great and I learned a lot of things for when I do my next fiberglass project. Now I just need to decide if I want to paint the fiberglass or use another layer of epoxy with black pigment. If I go the epoxy route I will most likely have to buy additional epoxy which will make it much more expensive than using a black paint. If anyone has experience with painting fiberglass I would love to hear your thoughts. Especially on what paint to use.

I did not sand the wood smooth so there are some places the fiberglass did not stick to it because there were gouges in the wood. But as you can see by far the majority of the fiberglass stuck to the wood. This was more than good enough for what I needed.

Everything I read about fiberglassing vertically required the use of a filler to thicken the epoxy so it would not fall down the wall and pool at the bottom. Therefore, I bought the recommended filler and applied it to the recommended thickness. What a disaster this became! First, it was almost impossible to force the epoxy through the fiberglass. Luckily I used the extra slow hardener for this stuff will harden long before we got the fiberglass to stick to the foam and I was only able to get the fiberglass to stick to the foam by pulling the fiberglass up and applying some epoxy directly to the foam and then laying the fiberglass back down. Luckily we were able to eventually get it to stick. The areas that are less transparent is where the filler was used. After that we did not use anymore filler and the job became easier and quicker.

We did end up having one more problem. The places we used the filler, ended up separating from the phone once we applied the second layer of fiberglass. Thus, when you look at the camper the top part of the step probably has about 40% separation from the foam while the bottom part is about 1% separated. The 1% represents areas I did not get the foam surface perfectly smooth.

I feel the bottom of the camper looks really good.

Here I have removed the excess fiberglass and all of the plastic.

We did have some other smaller issues that will be easy to fix before I finished the fiberglass. This is an area where the fiberglass did not sit down all the way so I cut it off and will apply a patch of fiberglass and epoxy.

In this pic the really white part is where the fiberglass separated from the foam.

Looks like I overlooked the surface law and have a gap between the metal and foam but it is small enough I am not worried about it. For the areas that look like blisters I will most likely send them down and patch the fiberglass. But again, given this will set inside the bed of the truck I don't not want to spend too much time trying to make it perfect. As long as it is waterproof and strong enough to prevent cracks or breakage it will serve its purpose.

Overall I think it turned out great and I learned a lot of things for when I do my next fiberglass project. Now I just need to decide if I want to paint the fiberglass or use another layer of epoxy with black pigment. If I go the epoxy route I will most likely have to buy additional epoxy which will make it much more expensive than using a black paint. If anyone has experience with painting fiberglass I would love to hear your thoughts. Especially on what paint to use.

You might want to look at:

epoxycraft.com

epoxycraft.com

"Both pigments and WEST SYSTEM 420 Aluminum

Powder provide protection from sunlight. Epoxy breaks

down under prolonged exposure to ultraviolet light; if

you do not plan to coat your hull with a finish system

immediately, add either pigment or powder to your last coat of epoxy.

This is a temporary measure which does

not replace a final paint finish." is from:

Rudder Repair

By Tom Pawlak — GBI Technical Advisor A typical spade rudder for sailboats is made up of two fiberglass skins that define the shape of the rudder, a metal mandrel that is an extension of the rudder post, and foam core which bridges the space between the skins and mandrel. In order for a rudder...

"Both pigments and WEST SYSTEM 420 Aluminum

Powder provide protection from sunlight. Epoxy breaks

down under prolonged exposure to ultraviolet light; if

you do not plan to coat your hull with a finish system

immediately, add either pigment or powder to your last coat of epoxy.

This is a temporary measure which does

not replace a final paint finish." is from:

ITTOG

Well-known member

Interesting, I have never seen that last statement anywhere else. I guess I will paint it! Thank you very much for including that.You might want to look at:

Rudder Repair

By Tom Pawlak — GBI Technical Advisor A typical spade rudder for sailboats is made up of two fiberglass skins that define the shape of the rudder, a metal mandrel that is an extension of the rudder post, and foam core which bridges the space between the skins and mandrel. In order for a rudder...epoxycraft.com

"Both pigments and WEST SYSTEM 420 Aluminum

Powder provide protection from sunlight. Epoxy breaks

down under prolonged exposure to ultraviolet light; if

you do not plan to coat your hull with a finish system

immediately, add either pigment or powder to your last coat of epoxy.

This is a temporary measure which does

not replace a final paint finish." is from:

You are welcome!Interesting, I have never seen that last statement anywhere else. I guess I will paint it! Thank you very much for including that.

Time: 3 hours

Total Time to Date: 224 hours

Rework: 0 hours

Total Rework to Date: 79 hours (not part of time above)

Current Weight: 651 pounds

Roof: 123 (need to reweigh and add lift support weight)

Camper: 480 (calculated)

Wedge Weight: 48

These are the latches I plan to use to latch the roof to the camper. They are way beefier than required but I didn't like they were made to fit only a 4mm bolt. So I drilled them out to accept 6mmx1.0 and beveled the heads so the screws will sit flush and not interfere with the latch. This first pic shows the first one I had converted.

View attachment 725324

After about an hour I had all of them drilled out and beveled.

View attachment 725325

Thank goodness for sons. I have been itching for working a little on the camper but knew I wouldn't be able to get the camper of the trailer and turned over. So in comes my son. We have traded roles of providing the muscle around the house. That is probably true even when I haven't had surgery.

I filled in the holes and flaws in the plywood and then sealed it so it doesn't soak in all the epoxy when I fiberglass it.

View attachment 725326

In order to fiberglass the tub of the camper I needed some walls to lay the glass on. I decided to use, with the help of @AbleGuy, 2" foam board. My tubing is 1.5" thick, thus the inside of the camper will have about 1/2" thick foam over the tubing and 2" elsewhere. This should help reduce condensation with temps in the 20F and higher. Any lower and I will probably see some condensation by the tubing.

View attachment 725327

In order to install it I used a hot knife to cut out the locations of the tubing. For straight-line cuts it is like a hot knife in butter. But when cutting out the interior grooves it takes a bit more pressure and is a lot slower. But it does work.

View attachment 725328

View attachment 725329

Here it is installed and you can see the 1/2" over the tubing.

View attachment 725330

First piece fully installed. Upon final installation I plan to glue it and fill gaps with expanding foam.

View attachment 725331

View attachment 725332

Before I put my camper in storage I put a piece of tubing on the camper with 3M tape, 4991. I affixed the tube around April 10 so it was on the camper almost two months. I used isopropyl alcohol to clean the bare steel and the paint before applying the 3M tape. You will see in the video that the tape came off the paint, without damaging the paint or the tape. I was able to pull it off the bare steel as well but it was more difficult. The first pull in the video is just me pulling with one hand and it passed that test. But when I pushed off the camper with the other hand it came off pretty easily. Thus, this tape probably needs a primer or something to make it work better. I also have 3M 5952 so I need to test it. Hopefully it will work without a primer.

ARGH ! I ordered about $1k of 4950... was planning to adhere my fiberglass over plastic honey comb panels to the painted steel... guess I will do a test with the pannels... Are you going to use rivets now or just adhesive or a combo of adhesive and tape which is something I was thinking of doing... That test was depressing...

ITTOG

Well-known member

Don't forget that I used isopropyl alcohol and no primer, or whatever they call it. So with the right primer you might find better results. I ended up using a different tape, 5952, that did much better. I posted a video of its performanc a few posts later. I plan to use the 5952 tape and Sikaflex for adhesion. I then plant to use angle iron on all the corners. I am thinking about welding all the angle together so that you cannot remove it without cutting it. I am hoping by doing this It will sandwich the skin to the camper and I will not have to use rivets, or at least will greatly reduce the number I use.ARGH ! I ordered about $1k of 4950... was planning to adhere my fiberglass over plastic honey comb panels to the painted steel... guess I will do a test with the pannels... Are you going to use rivets now or just adhesive or a combo of adhesive and tape which is something I was thinking of doing... That test was depressing...

ITTOG

Well-known member

Primarily because I was looking for something easy. This part will be hidden inside the bed of the truck so I am not too concerned about looks. Also, there are some fiberglass delamination spots. Using a paint will make it easier to repair in the future.Why not just use gel coat? It can be had in black and is designed to go on fiberglass

Sent from my iPhone using Tapatalk

ITTOG

Well-known member

Time: 4 hours

Total Time to Date: 258 hours

Rework: 0 hours

Total Rework to Date: 79 hours (not part of time above)

Current Weight: To be weighed, but at least 660 pounds

Before I could paint the fiberglass I needed to make some repairs to some of the worse areas. Some of the problems were with the delamination and somewhere with air bubbles. So I cut and/or sanded the issues out and repaired them. I did not take any pictures of that process.

For paint I use TotalBoats Wet Edge Marine Topside Paint.it goes on easily and is supposed to cure to a hard finish. I am around 48 hours of the total 72 hours required for curing. You can see a few patches I made in this picture. I was not worried about patch edges showing up given this area will set inside the truck. So there are some issues with the final job but it will definitely keep everything dry which is all I really cared about. I had a great adhesion between the fiberglass and steel frame of the camper so I do not expect any issues there.

The finished job. As I said, you can see blemishes but nothing I am worried about.

Once the paint is fully cured I will flip the camper over and get more pictures. I am excited to see it upright with most of the tub in place. I was supposed to have surgery on my other hip today but it was canceled because the doctor was sick. So I may be able to do some additional work before putting it up for two months.

Total Time to Date: 258 hours

Rework: 0 hours

Total Rework to Date: 79 hours (not part of time above)

Current Weight: To be weighed, but at least 660 pounds

Before I could paint the fiberglass I needed to make some repairs to some of the worse areas. Some of the problems were with the delamination and somewhere with air bubbles. So I cut and/or sanded the issues out and repaired them. I did not take any pictures of that process.

For paint I use TotalBoats Wet Edge Marine Topside Paint.it goes on easily and is supposed to cure to a hard finish. I am around 48 hours of the total 72 hours required for curing. You can see a few patches I made in this picture. I was not worried about patch edges showing up given this area will set inside the truck. So there are some issues with the final job but it will definitely keep everything dry which is all I really cared about. I had a great adhesion between the fiberglass and steel frame of the camper so I do not expect any issues there.

The finished job. As I said, you can see blemishes but nothing I am worried about.

Once the paint is fully cured I will flip the camper over and get more pictures. I am excited to see it upright with most of the tub in place. I was supposed to have surgery on my other hip today but it was canceled because the doctor was sick. So I may be able to do some additional work before putting it up for two months.

ITTOG

Well-known member

Time: 7 hours

Total Time to Date: 265 hours

Rework: 0 hours

Total Rework to Date: 79 hours (not part of time above)

Current Weight: To be weighed, but at least 660 pounds

After letting the paint cure for 72 hours I turned the camper upright and set it on a dolly. It was a little exciting to see it as it will sit in the truck.

Today's work was to fabricate the anchor points for the latches that hold the roof down. The top screw will attach to a barrel nut in the top tube and the bottom two screws will attach to 1/8" steel plate.

This is the back side and you can see the back of the barrel nut, which is just a 1/2" diameter by 1.5" long rod that I drilled and tapped for a M6x1.0 thread. The barrel nut is the shiny silver circle.

For the top part of the latch both screws will be attached to barrel nuts. The barrel nuts get welded to the tube on both sides to help distribute load stresses.

Just mocking up the top latch placement on the roof. This is two 1.5" tubes but the roof is actually one 3" tube. After seing the mock up I think I will put the latch towards the bottom of the 3" tube as in the first photo.

Tools of the trade.

A shot from the back of the camper through the entry door.

A shot from the top of the camper looking down at the floor. The front of the camper is at the top of the pic.

Looking good. I can't wait to see it in the truck.

Total Time to Date: 265 hours

Rework: 0 hours

Total Rework to Date: 79 hours (not part of time above)

Current Weight: To be weighed, but at least 660 pounds

After letting the paint cure for 72 hours I turned the camper upright and set it on a dolly. It was a little exciting to see it as it will sit in the truck.

Today's work was to fabricate the anchor points for the latches that hold the roof down. The top screw will attach to a barrel nut in the top tube and the bottom two screws will attach to 1/8" steel plate.

This is the back side and you can see the back of the barrel nut, which is just a 1/2" diameter by 1.5" long rod that I drilled and tapped for a M6x1.0 thread. The barrel nut is the shiny silver circle.

For the top part of the latch both screws will be attached to barrel nuts. The barrel nuts get welded to the tube on both sides to help distribute load stresses.

Just mocking up the top latch placement on the roof. This is two 1.5" tubes but the roof is actually one 3" tube. After seing the mock up I think I will put the latch towards the bottom of the 3" tube as in the first photo.

Tools of the trade.

A shot from the back of the camper through the entry door.

A shot from the top of the camper looking down at the floor. The front of the camper is at the top of the pic.

Looking good. I can't wait to see it in the truck.

Last edited:

ITTOG

Well-known member

Yes it is. Kind of exciting to see it start to look like a camper. I am hoping to cut one of the skins for the top this weekend, if I can find the time. If not, it will probably be a couple months before I can get back to it, which would suck.Making progress!

ITTOG

Well-known member

Time: 2 hours

Total Time to Date: 267 hours

Rework: 0 hours

Total Rework to Date: 79 hours (not part of time above)

Current Weight: To be weighed, but at least 660 pounds

Not much was done because I had to move the trailer to storage since I am having surgery on my hip Friday. Thus, this will be the end of work for the next six to eight weeks. However, I had to cut out one panel before putting in storage. I used a router for most of it. That made it very quick and easy to cut but made a huge mess. I wanted to remove the protective wrap but decided that would guarantee it gets scratched. Without any further ado.

From the side.

I did pull the protective wrap back on one scrap piece. The color is a flat black.

Total Time to Date: 267 hours

Rework: 0 hours

Total Rework to Date: 79 hours (not part of time above)

Current Weight: To be weighed, but at least 660 pounds

Not much was done because I had to move the trailer to storage since I am having surgery on my hip Friday. Thus, this will be the end of work for the next six to eight weeks. However, I had to cut out one panel before putting in storage. I used a router for most of it. That made it very quick and easy to cut but made a huge mess. I wanted to remove the protective wrap but decided that would guarantee it gets scratched. Without any further ado.

From the side.

I did pull the protective wrap back on one scrap piece. The color is a flat black.

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 2

- Views

- 648

- Replies

- 3

- Views

- 670

- Replies

- 3

- Views

- 519