ITTOG

Well-known member

Time: 10 hours

Total Time to Date: 289.5 hours

Rework: 0 hours

Total Rework to Date: 79 hours (not part of time above)

Current Weight: To be weighed, but at least 660 pounds

These family commitments are making it hard to make progress but I was finally able to make a little. I did some bondo work and was able to get the back skin on the camper.

I began by sanding the first coat of bondo glass on the camper. As you can see I do have good bondo coverage but I have some spots where the metal shines through. So I may have to do three or four coats to get the desired thickness.

This is the curb side. A bit more metal showing through so I was not consistent on my thickness but this side was the first time I had ever used bondo.

This is the street side and after the second coat of bondo was applied. I used a little less hardener and was able to get this coat a little thicker and smoother.

The primary reason I did not have time to put skins on the side is because I decided to attach my VHB tape to bare metal. This decision was made because I ran a test and the tape held strongly on the paint but I was able to roll it off without the tape tearing or leaving residue behind. This was not the case on the metal. On the metal the tape would tear and I was not able to roll it off. Thus I had to sand off some of the paint and then had to do a major cleanup before applying VHB tape.

These pics show all of the VHB tape applied to the camper.

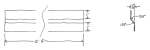

The leading edge of the skin near the bondo will slide into the groove in this pic. This is to ensure wind and rain will never be able to get underneath the skin when driving 85 mph down the road.

After applying the skin to the camper I lightly applied pressure using bars and clamps to ensure I get solid adhesion with the VHB tape. It also helped thin the Sikaflex 252 appropriately.

Total Time to Date: 289.5 hours

Rework: 0 hours

Total Rework to Date: 79 hours (not part of time above)

Current Weight: To be weighed, but at least 660 pounds

These family commitments are making it hard to make progress but I was finally able to make a little. I did some bondo work and was able to get the back skin on the camper.

I began by sanding the first coat of bondo glass on the camper. As you can see I do have good bondo coverage but I have some spots where the metal shines through. So I may have to do three or four coats to get the desired thickness.

This is the curb side. A bit more metal showing through so I was not consistent on my thickness but this side was the first time I had ever used bondo.

This is the street side and after the second coat of bondo was applied. I used a little less hardener and was able to get this coat a little thicker and smoother.

The primary reason I did not have time to put skins on the side is because I decided to attach my VHB tape to bare metal. This decision was made because I ran a test and the tape held strongly on the paint but I was able to roll it off without the tape tearing or leaving residue behind. This was not the case on the metal. On the metal the tape would tear and I was not able to roll it off. Thus I had to sand off some of the paint and then had to do a major cleanup before applying VHB tape.

These pics show all of the VHB tape applied to the camper.

The leading edge of the skin near the bondo will slide into the groove in this pic. This is to ensure wind and rain will never be able to get underneath the skin when driving 85 mph down the road.

After applying the skin to the camper I lightly applied pressure using bars and clamps to ensure I get solid adhesion with the VHB tape. It also helped thin the Sikaflex 252 appropriately.

Last edited: