I’ve been following all the fiberglass projects, but we haven’t seen you build a fg box yet! Sounds silly, but I want to see how you build something “simple” like a box.

I haven't made anything as simple as a box before, but the military trailer lid I made is basically a box so I'll show the steps for that project. The steps for making a box are pretty much the same.

I started by making a mold master out of MDF:

I use MDF often for this because it's perfectly flat and smooth, cuts easily, takes a finish nicely and it's not expensive.

Then I put a nice finish on it. Whatever finish (and flaws) are on the surface will be faithfully reproduced in the mold and on the final product.

I made a mold on it, I'll skip those steps, here's the finished mold:

One thing to notice about the mold - there are boards bolted to around the top of the mold - these are forms used to make an inward-facing flange around the edge. I would do the same thing for a weatherproof box, the inward-facing flange give the cover something to seal against. The board facing front in the photo is removable, I did that to make it easier to get the finished lid out of the mold (more on that technique in moment).

To begin making the "box", the inside of the mold is shot with gelcoat:

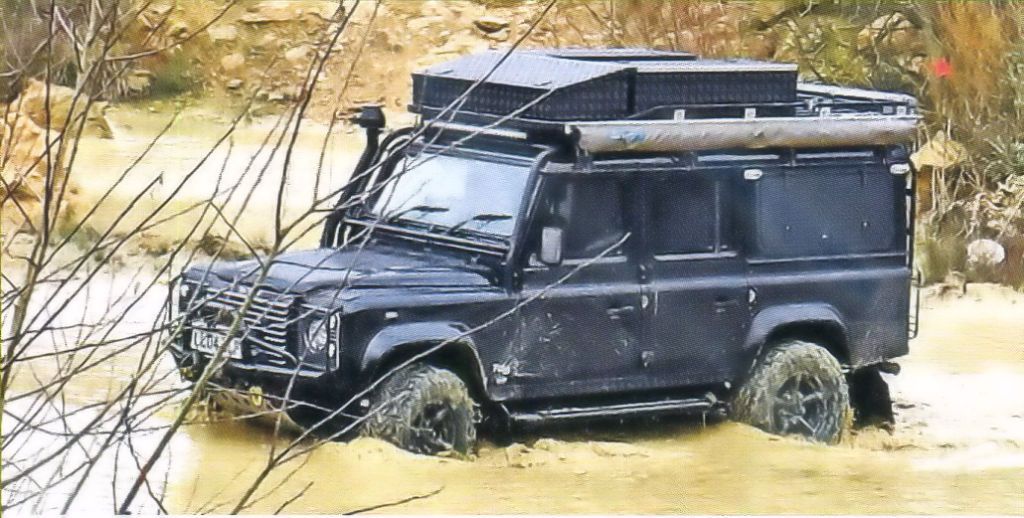

And once that's cured to the right point, the fiberglass is laid up. I added ribs to the lid to make it strong enough to support a roof top tent and reinforcement pads where the bolts for a roof top tent will go through.

The lid has been popped out of the mold in these next photos, in the first photo you can see the inward-facing lip.

I made the mold for half a cover, the two halves get bolted together to form the full lid. In this next photo, the 225-lb. gorilla test is being done to verify that the lid is strong enough...

The "box" above is not very deep and there's one more consideration when making a mold for a deeper box - draft angle. To allow a deep box to be removed from the mold, one (or both) of two techniques has to be used:

1. Draft angle. A box with perfectly vertical sides won't slip out of the mold very easily, so the sides need to be angled very slightly - the top of the box needs to be slightly larger than the bottom of the box, this is called draft angle.

2. To make a box without draft angle it would be best to make a multi-part mold - a mold that bolts together in the corners. The mold parts are bolted together, the box is molded in the mold and then to remove the box from the mold the mold is disassembled. The inward-facing flanges I did on the trailer lid above are bolt-on parts to the mold, it's the same idea except the entire mold would come apart.

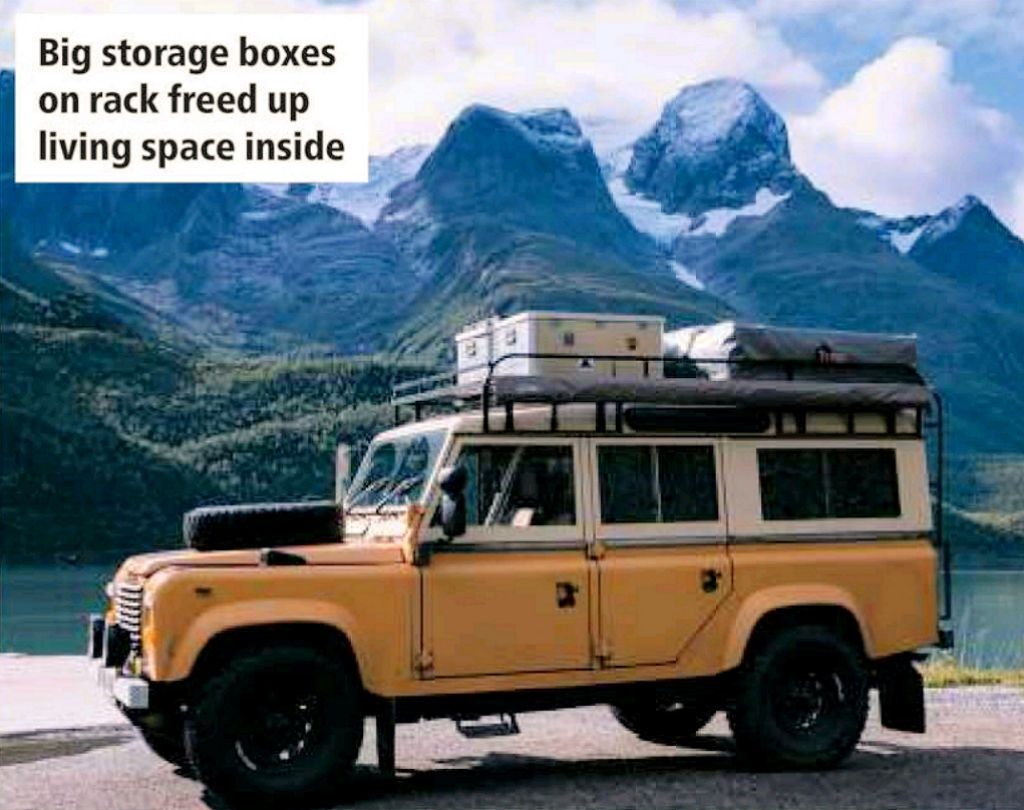

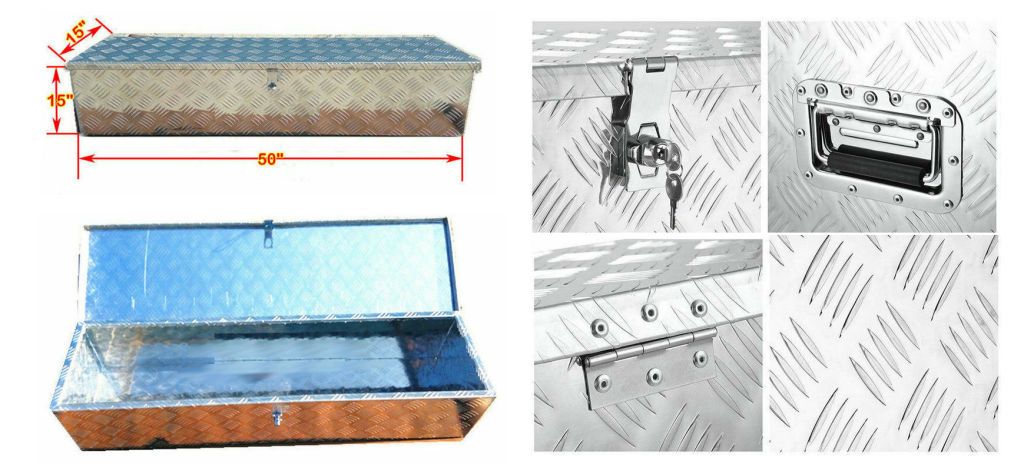

If I decide to make a roof rack box out of fiberglass, I'd probably do it with a diamondplate surface texture. I've got a brand-new 4x8 sheet of thin aluminum diamondplate here, it's too thin to make a box out of but if could be used as a skin for a mold master. I'd make a wooden mold master box, skin it with this thin diamondplate and then make a mold from that. The resulting boxes out of the mold would look just like a metal diamondplate box. A box with a diamondplate surface texture would need to be made in a multipart mold; the raised bumps in the diamondplate would lock the box into the mold so the only way to get the box out of the mold would be to make a mold that can be disassembled.

.jpg?width=1920&height=1080&fit=bounds)