Metcalf

Expedition Leader

Just a little detail.

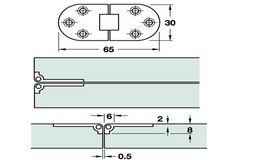

I have been thinking about the sleeping platform and how it will flip/slide forward over the passenger seat and center console. It took me a bit but I think these hinges would be a simple and clean solution to having the platform flip forward in one or more section. I think with the roll bar the platform might need to flip forward in two sections to make eveything clear inside. Anyways....cool little hinges.

http://www.sdslondon.co.uk/product/self-supporting-folding-table-hinge-1.html

This style of hinge allows everything to fold flat back 180 degrees on itself. They also kinda self support the multiple panels. I won't rely on the hinges to support everything but it can't hurt.

I am thinking maybe some plywood with lots of holes to make a light platform? The platform will only have a 36" unsupported width between the wheel tubs. The forward leaves can be supported on the center console, a small bracket on the roll bar, the seat back, and perhaps the grab handle on the dash. I may also have a separate leaf on the drivers side to give a little more room when sleeping two people.

My basic organization plan for camping inside on solar trips is to have my personal gear bag strapped to the deck behind the drivers seat far over the drivers side toward the window. My bed roll can be on the opposite side. It will basically be my foam sleeping pad, sleeping bag, and pillow all rolled up in one unit. It should be simple to store and unroll for use. The kitchen box and a small cooler may fit behind the spare tire ( on the rear forward floor ) and the tailgate.

I was looking at another LJ in real life today.....they really are not THAT big. I will need to be careful with space....

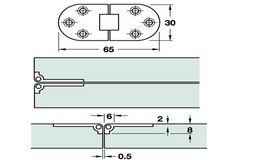

I have been thinking about the sleeping platform and how it will flip/slide forward over the passenger seat and center console. It took me a bit but I think these hinges would be a simple and clean solution to having the platform flip forward in one or more section. I think with the roll bar the platform might need to flip forward in two sections to make eveything clear inside. Anyways....cool little hinges.

http://www.sdslondon.co.uk/product/self-supporting-folding-table-hinge-1.html

This style of hinge allows everything to fold flat back 180 degrees on itself. They also kinda self support the multiple panels. I won't rely on the hinges to support everything but it can't hurt.

I am thinking maybe some plywood with lots of holes to make a light platform? The platform will only have a 36" unsupported width between the wheel tubs. The forward leaves can be supported on the center console, a small bracket on the roll bar, the seat back, and perhaps the grab handle on the dash. I may also have a separate leaf on the drivers side to give a little more room when sleeping two people.

My basic organization plan for camping inside on solar trips is to have my personal gear bag strapped to the deck behind the drivers seat far over the drivers side toward the window. My bed roll can be on the opposite side. It will basically be my foam sleeping pad, sleeping bag, and pillow all rolled up in one unit. It should be simple to store and unroll for use. The kitchen box and a small cooler may fit behind the spare tire ( on the rear forward floor ) and the tailgate.

I was looking at another LJ in real life today.....they really are not THAT big. I will need to be careful with space....