You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

M416 trailer build my brother and I

- Thread starter Crush Jeep

- Start date

Mark Harley

Expedition Leader

Very nice fab work and design!

Crush Jeep

Adventurer

So the tongue box that he had on it was scrapped and he went another way with the box. The sheet metal had one bend put into it and the rest had to be welded together.

So here is the new box shape, the same as the trailer tub. No Harbor Freight tongue box here, it's all home made.

The tongue box is an extension of the tub.

The start of the tailgate.

So here is the new box shape, the same as the trailer tub. No Harbor Freight tongue box here, it's all home made.

The tongue box is an extension of the tub.

The start of the tailgate.

Mark Harley

Expedition Leader

Would you guys be willing to adopt another brother?

Love the first build.....and the second one is way cool too!

Love the first build.....and the second one is way cool too!

Crush Jeep

Adventurer

Well Mark we are originally from the Poconos in PA so you could be a long lost brother.Would you guys be willing to adopt another brother?

Love the first build.....and the second one is way cool too!

Crush Jeep

Adventurer

So a few more pictures. The fenders were purchased at Northern Tool, they were not wide enough for the tires so the fenders were cut in half and extended a few inches to accommodate the tires.

Here's the fender on the trailer. You can see where it was extended on these pictures. You will not be able to notice it on the finished product.

Here's the lid / top that was fabricated, it was opposite of the bottom. Unlike when we worked on my lid the tub is square on this one. It makes it much easier.

The finished product of the lid. This trailer is going to weigh a lot more then my trailer.

The axel and springs are 3500 pound and the lug pattern is for a Toyota Tacoma.

Here's the fender on the trailer. You can see where it was extended on these pictures. You will not be able to notice it on the finished product.

Here's the lid / top that was fabricated, it was opposite of the bottom. Unlike when we worked on my lid the tub is square on this one. It makes it much easier.

The finished product of the lid. This trailer is going to weigh a lot more then my trailer.

The axel and springs are 3500 pound and the lug pattern is for a Toyota Tacoma.

Crush Jeep

Adventurer

Here's a few more pictures that I just found. This is the tongue jack from my trailer that was changed out. This trailer is a little taller so we will be able to cut the foot plate off and replace it with a wheel.

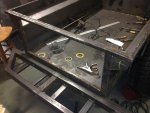

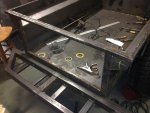

Here are some shots of the tub being built. At the metal shop you can get them to place a bend in the metal. So the first angle was bent and the other was welded on.

The top welds completed and to front of the tub welded.

Here are some shots of the tub being built. At the metal shop you can get them to place a bend in the metal. So the first angle was bent and the other was welded on.

The top welds completed and to front of the tub welded.

highlandercj-7

Explorer

Why would you not have them bend it twice and save all that weld time?

Crush Jeep

Adventurer

Good question, the bend has to be at least 9 inches apart to fit on the machine, so there's the issue, I think the second bend is 6 or 7 inches from the first. If they would put the second one in there it would save a lot of time.Why would you not have them bend it twice and save all that weld time?

VanIsle_Greg

I think I need a bigger truck!

Looking great.

Crush Jeep

Adventurer

Here's a few more pictures of the progress.

The main box open and the start of the roof rack.

Roof rack with the adjusters on it for the RTT.

Both boxes open.

If you look at the center of the tongue box you will see the winch for the generator.

Next it's going to be painted and then all the small finishing touches.

The main box open and the start of the roof rack.

Roof rack with the adjusters on it for the RTT.

Both boxes open.

If you look at the center of the tongue box you will see the winch for the generator.

Next it's going to be painted and then all the small finishing touches.

Crush Jeep

Adventurer

Crush Jeep

Adventurer

Here's a few of the finishing touches. Mounted the vin tag on the tongue and had the sheriff come by and inspect it. The tags will be next.

Of course you have to have the bottle opener.

Wood inlay in the tailgate.

The wiring for the battery box. I know it's hard to see but it's a six switch marine switch to operate the lights.

It has not been weighed yet but it's going to be heavy. It's well built and bullet proof almost like this.

The floor in the garage was repainted, the black trailer sucked all the light out of the room. My brother needed to brighten it up, he said it was too depressing in there.

Of course you have to have the bottle opener.

Wood inlay in the tailgate.

The wiring for the battery box. I know it's hard to see but it's a six switch marine switch to operate the lights.

It has not been weighed yet but it's going to be heavy. It's well built and bullet proof almost like this.

The floor in the garage was repainted, the black trailer sucked all the light out of the room. My brother needed to brighten it up, he said it was too depressing in there.

Crush Jeep

Adventurer

Some final pictures of the trailer as it is finished up.

On board air.

Another picture of the air hose and bottle opener (some of you my recognize the insignia on the opener), a little special touch.

A few more pictures from the inside of the front box with and without the shelf.

The winch controller and scissor jack handle.

On board air.

Another picture of the air hose and bottle opener (some of you my recognize the insignia on the opener), a little special touch.

A few more pictures from the inside of the front box with and without the shelf.

The winch controller and scissor jack handle.

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 20

- Views

- 5K

- Replies

- 27

- Views

- 5K

- Replies

- 6

- Views

- 3K

Forum statistics

Members online

- Reeces Pieces

- gnel

- Trailrunnerdad

- Recon1342

- 85_Ranger4x4

- avlfj40

- Crazy Schooner

- karlfunk

- matttahoe53

- Undergroundroot

- BP89

- JDaPP

- 94LandCruiserDude

- mark5280

- ValveCoverGasket

- zelseman

- ARDOR

- Obsessed2findARuggedHybid

- roaming.nomads

- Pskhaat

- Gabe357

- g_m

- Hegear

- Pauly1980

- jruba

- perlhammer

- ovrland6250

- coski

- TheTrailWhale

- Expedit

- porteur

- valcon1

- austastar

Total: 3,113 (members: 36, guests: 3,077)