Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Metal frame or 3/4" plywood box?

- Thread starter Mox1968

- Start date

Teardropper

Well-known member

Wood some day will rot are break .

Any poorly built trailer will have a limited lifespan no matter what material is used.

I'm working on my fourth teardrop. I use wood. The other three are cruising like there is no tomorrow and should end up in the owner's wills.

I suggest using the material you are most familiar with and have the necessary tooling to do the job.

Tony

Teardropper

Well-known member

If you eliminate rain, snow, moisture in the off season. you reduce the reasons to not use wood.

They do need to be properly stored.

T

Photomike

White Turtle Adventures & Photography

I have built a couple trailers with wood.

The first one was a 4x8 trailer with a box on it 4' high, 1/4" plywood. It was NOTHING fancy and I used it for hauling my bicycles to keep them secure and dry. It had a flat roof on it and nothing special. I stained it and used it for 6 years without an issue. It stayed outside 24/7/365 when I sold it I had not used it for several years and just had stuff inside and it was still perfectly dry and zero rot.

The second one I built I took a lot more time and care. The unit was soild and not that heavy but not a light weight. 4'x8'x36" high, used 1/2" and it was like a rock. Only issue with this one was I put a front access in and it would leak in strong rain storms when I was pulling it. I mounted three bikes on the roof and they were perfectly solid there. Used that for 8 years and when I sold it it was as good as the day it was built with the exception of a little rot at the front where I had the leak (poor design more than poor product).

I built out of standard plywood as I could work with it and it was affordable.

The first one was a 4x8 trailer with a box on it 4' high, 1/4" plywood. It was NOTHING fancy and I used it for hauling my bicycles to keep them secure and dry. It had a flat roof on it and nothing special. I stained it and used it for 6 years without an issue. It stayed outside 24/7/365 when I sold it I had not used it for several years and just had stuff inside and it was still perfectly dry and zero rot.

The second one I built I took a lot more time and care. The unit was soild and not that heavy but not a light weight. 4'x8'x36" high, used 1/2" and it was like a rock. Only issue with this one was I put a front access in and it would leak in strong rain storms when I was pulling it. I mounted three bikes on the roof and they were perfectly solid there. Used that for 8 years and when I sold it it was as good as the day it was built with the exception of a little rot at the front where I had the leak (poor design more than poor product).

I built out of standard plywood as I could work with it and it was affordable.

billiebob

Well-known member

I call that the recipe for rot.They do need to be properly stored.

T

Definitely not stored in a garage.

Zero room for air to circulate. The tarp traps moisture.

IdaSHO

IDACAMPER

Built correctly, with proper materials, methods, and design your camper should never need shelter.

We have had ours on the road since 2012.

Never seen the underside of a roof since.

Never a problem, not a single repair to the exterior since.

And yes, its wood.

VG fir frame

XPS foam rigid insulation

3mm ply interior skins

6mm bs1088 okoume ply exterior skins

Epoxy coated, glassed, and painted.

We have had ours on the road since 2012.

Never seen the underside of a roof since.

Never a problem, not a single repair to the exterior since.

And yes, its wood.

VG fir frame

XPS foam rigid insulation

3mm ply interior skins

6mm bs1088 okoume ply exterior skins

Epoxy coated, glassed, and painted.

Teardropper

Well-known member

I call that the recipe for rot.

Definitely not stored in a garage.

Zero room for air to circulate. The tarp traps moisture.

Sorry, Billiebob. It's been winter-stored with that cover for six years. No rot. No moisture. No scratches on the aluminum.

From the manufacturer: "Adjustable front and rear tension panels and elasticized hem corners provide a custom fit, integrated air vent system combined with quick drying PolyPRO™ 1 sides reduce wind stress and vent inside moisture"

What you don't understand is that the 'drop is covered with aluminum. The edges are sealed. The exterior plywood underneath is sealed with epoxy. The interior wood is sealed with three coats of oil-based polyurethane.

Build it right. Store it right.

That's the real world, not the Internet.

T

Last edited:

Photomike

White Turtle Adventures & Photography

That's the real world, not the Internet.

T

So true!!! I stored my TCer and my motorhome outside not under cover for years and they were in perfect shape when I sold them. From the heat of summer to the winds of fall and the snow and -40C winter to the rains of spring - never covered and used as much as I could. Many said to me that you cannot do that because they read about it on the net - real life is better than a made up life!!

Built correctly, with proper materials, methods, and design your camper should never need shelter.

I like your method of construction. I am thinking about using 3/4 plywood on an teardrop sized camper. I would like to have large radius corners, in contrast to most boxy square corners on most homebuilt teardrops.

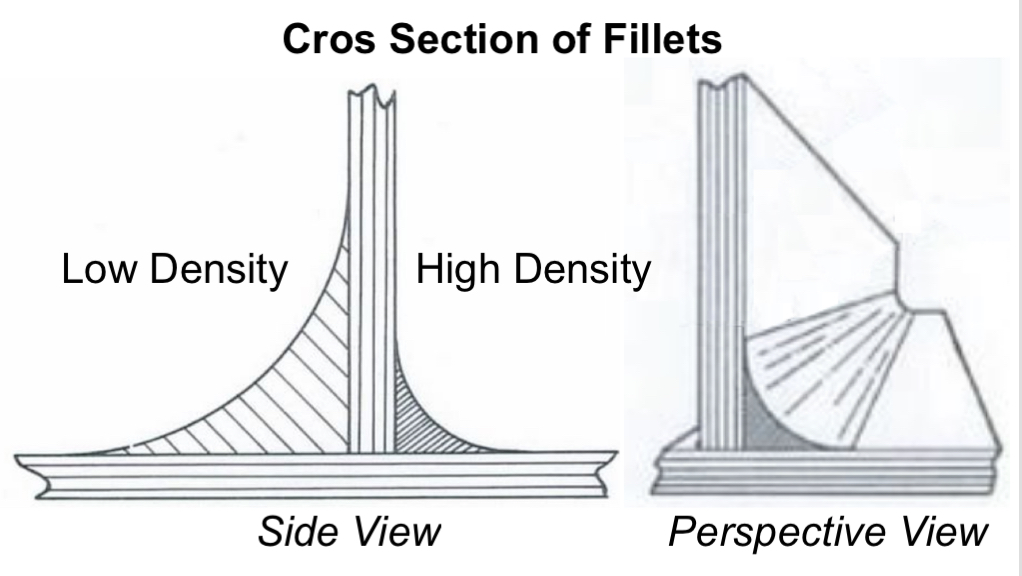

Do you think a router jig as shown in the drawing will help me achieve my dreams? Also shown in the drawing is an internal strip. 3/4 x 3/4. It will allow me to drive some screws prior to fiberglass. What do you think?

Yes the yellow is wood. I was thinking screws from the inside. I was thinking square would be good because I could drive screw both 90 degree directions.

Thanks for the info on fillets. Seems like there are many crossovers between camper building and boatbuilding. I think most of us would be better to lean towards the marine style of building and not as much build like a house

Thanks for the info on fillets. Seems like there are many crossovers between camper building and boatbuilding. I think most of us would be better to lean towards the marine style of building and not as much build like a house

IdaSHO

IDACAMPER

What adhesive are you using?

If it is PL Premium or any bonding epoxy you shouldn't need screws at all.

Wet set and brad nailed is more than enough.

Only time I use screws is if Im having trouble holding a joint together.

Screws are then used to tighten things up during assembly, then removed once cured.

I see screws under the surface as a liability. If they corrode, or loosed somehow, they can and will destroy the surface/paint/coating

If it is PL Premium or any bonding epoxy you shouldn't need screws at all.

Wet set and brad nailed is more than enough.

Only time I use screws is if Im having trouble holding a joint together.

Screws are then used to tighten things up during assembly, then removed once cured.

I see screws under the surface as a liability. If they corrode, or loosed somehow, they can and will destroy the surface/paint/coating

Yep. Planning to use PL premium.

I was thinking screws driven from the inside, but not too long that they protrude through the outside. Screws would partially function as clamps for the adhesive.

Also keep the screw back and away from the router.

What do you think of my “round over router jig” idea? I am hoping to try this idea on a small sample first.

I was thinking screws driven from the inside, but not too long that they protrude through the outside. Screws would partially function as clamps for the adhesive.

Also keep the screw back and away from the router.

What do you think of my “round over router jig” idea? I am hoping to try this idea on a small sample first.

Similar threads

- Replies

- 10

- Views

- 1K

- Replies

- 4

- Views

- 2K

- Replies

- 1

- Views

- 765

- Replies

- 1

- Views

- 906

- Replies

- 6

- Views

- 1K