slimtwo

Adventurer

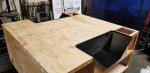

Yesterday, I got the sides all glued up, and I cut out the access hatch for the plumbing stuff; pump, pre-filter, valves and the like. I need to so the one for the other side, the propane bottle and fittings for that.

Today, I worked on the “positive air flow ventilation system”. I had an idea that I think will work very well. I have a 12 V server fan that puts out 640 cfm, at 1,500 rpm. It is fairly quiet, and should move a fair amount of air. I made the penetration in the front bulkhead, in the fridge compartment, so it will draw in fresh air, and push the heated air out.

And for the filter, I am using an air filter used for a riding lawnmower engine, 6” OD, and 4.5” ID (same as the fan). At this point, I just need to make a cover, to hold the filter in place.

My hope, is that the pressure will equalize through the whole box, and bleed off through the many gaps in the door seals. However, If I did to good a job with the weather stripping, I will install a tiny vent, so the air is aloud to move. The list of parts is pretty low cost. The fan cost about $18.00 bucks, and the filter and pre-filter was about $14.00 for two filter sets. I'm really anxious to see how it works. Another step closer to finishing.

Happy Trails!

Today, I worked on the “positive air flow ventilation system”. I had an idea that I think will work very well. I have a 12 V server fan that puts out 640 cfm, at 1,500 rpm. It is fairly quiet, and should move a fair amount of air. I made the penetration in the front bulkhead, in the fridge compartment, so it will draw in fresh air, and push the heated air out.

And for the filter, I am using an air filter used for a riding lawnmower engine, 6” OD, and 4.5” ID (same as the fan). At this point, I just need to make a cover, to hold the filter in place.

My hope, is that the pressure will equalize through the whole box, and bleed off through the many gaps in the door seals. However, If I did to good a job with the weather stripping, I will install a tiny vent, so the air is aloud to move. The list of parts is pretty low cost. The fan cost about $18.00 bucks, and the filter and pre-filter was about $14.00 for two filter sets. I'm really anxious to see how it works. Another step closer to finishing.

Happy Trails!