ben_j_c

Active member

Thanks for the kind words. I have a bio-electrical engineering degree and mostly do engineering & business management these days.What do you do for a living and what is your background?

Working on projects like this helps me keep my hands busy and learn new skills. I enjoy doing it all myself, it makes me understand all the systems that could break when I am out using it, and hopefully gives me good insight into fixing them when they eventually break.

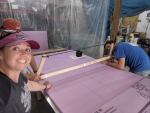

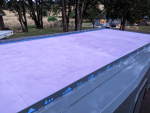

As to the skills and knowledge, it is mostly attitude and self confidence. You can do it too! This was my first time with serious aluminum fabrication (I built a few rafting tables before this to learn on), TIG welding, automotive painting, LASER cutting metal, differential work, insulated composite sandwiches, and more. Just take the time to research it and give it a try!

We see so many camper CAD builds that end at the CAD design.

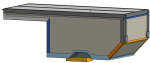

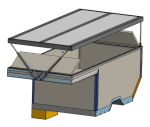

I certainly have more time into the CAD design and material selection than the fabrication. So much to think about when building a rig like this. For instance our entire rafting setup is designed to fit inside the camper, that alone took probably 30-50 hours of planning to make it all fit in CAD and I am working on the fabrication now. I went through probably 100 variations of the nose, hundreds of hours of work to hopefully hit my head less than I do in my Grandby!

I also have a graveyard of unbuild design iterations that I rejected before settling on this one. My favorite reject idea is a hard sided popup with linear actuators (link here: https://cad.onshape.com/documents/4...renderMode=0&uiState=6260e786a0700c52f6b1bebd )

I might build it some day, but it requires thinner panels than I had, the folding sides get too heavy to manage practically if there was ever a malfunction when they are 2.5" thick. Additionally the thick panels make the a fairly tall popup, but still a few inches shorter than the current design.

I am still shorter than most real RVs with the current design, so I figured it would work and keeps the first build simple. The down side is that I cannot fit in a shipping container assembled currently, so the camper has to come off the truck to all fit in a high cube container (and it only clears by 1.25 inches through the door) so I will need to rig up a special container with the gantry setup to facilitate fully enclosed overseas transport.

Anyway, if you ever decide to build one like this, let me know I will walk you through more of the decision making I went through and you are welcome to the CAD files.