luthj

Engineer In Residence

The bumper arrived a few days ago. Packaging was a bit Spartan, but it is a bumper… It's fairly beefy, but not overly so. I am not satisfied with the mounting provisions, so I will be making some brackets to attach it to the vans “frame” tubes.

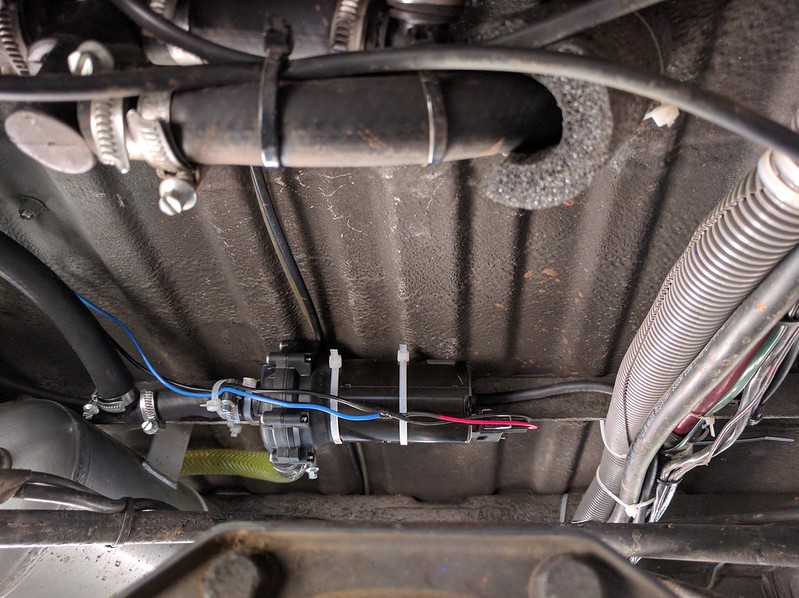

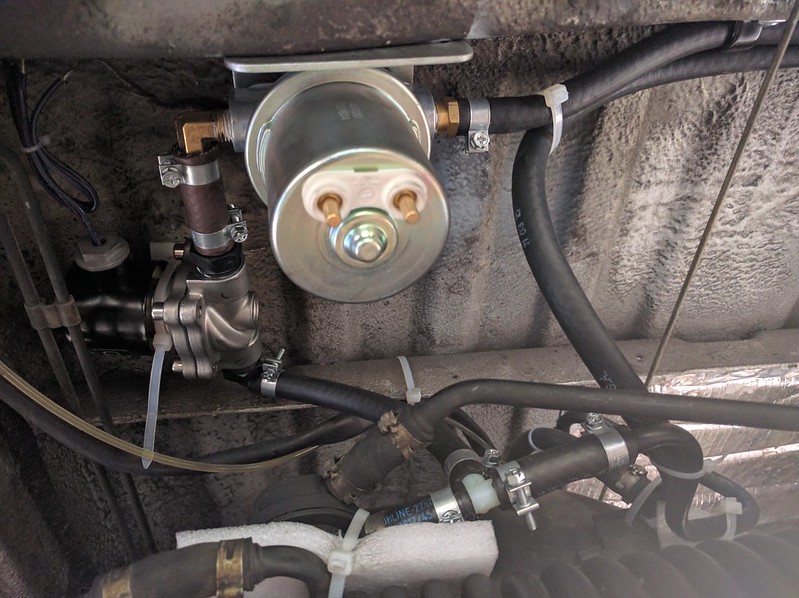

A friend of mine plasma cut and bent some steel sheet for me. It will become a fairly unusually shaped fuel tank. 16 gauge would have been ideal, but beggars cannot be choosers. So I will have a 10 gauge galvanized tank welded up soon. One of the bends is off a hair, so I will need to trim one edge before assembly. This may be a challenge with my limited tools.

The tank fits in the space under the sliding door and should be around 14 gallons. I could have gotten an 19 gallon tank to fit, but the alternator charging wire interferes, and it wasn't worth the cost to make a new one.

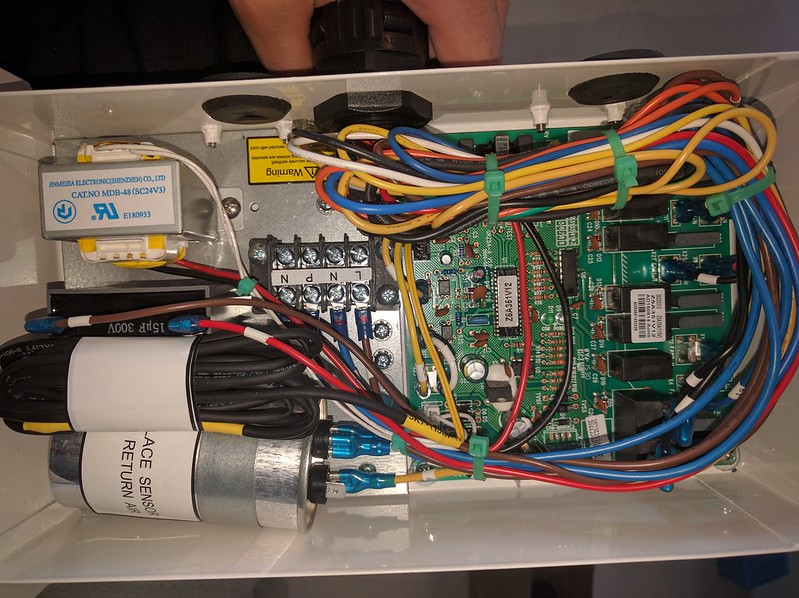

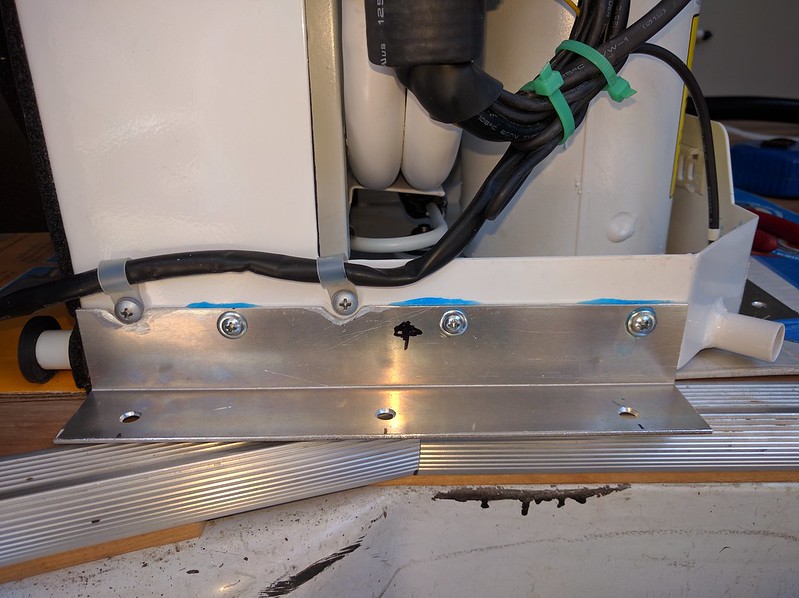

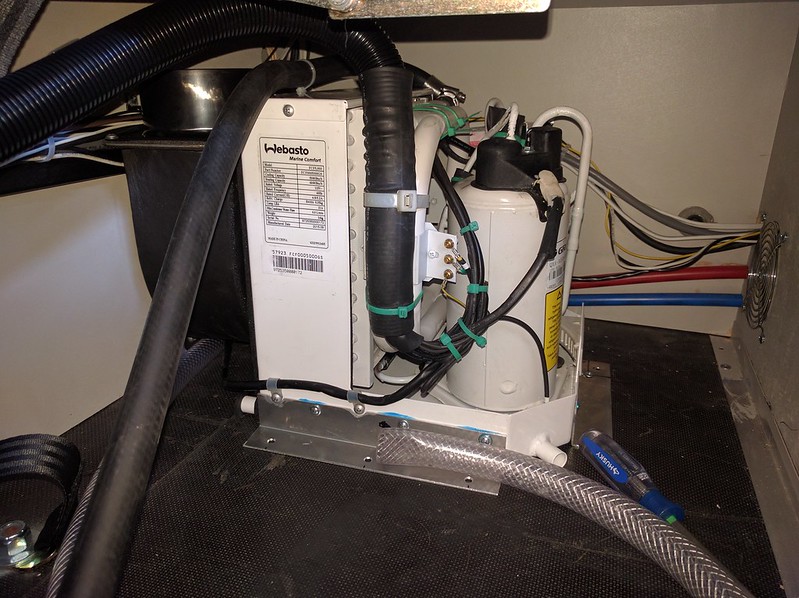

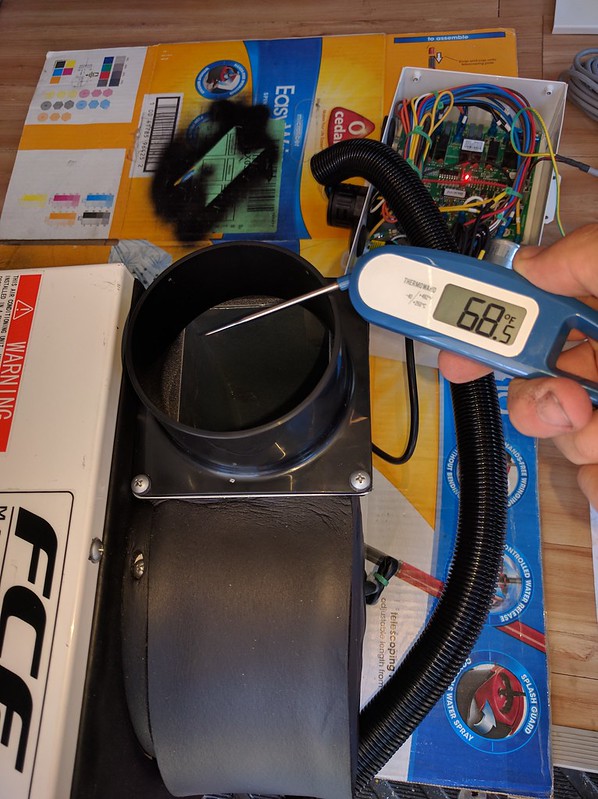

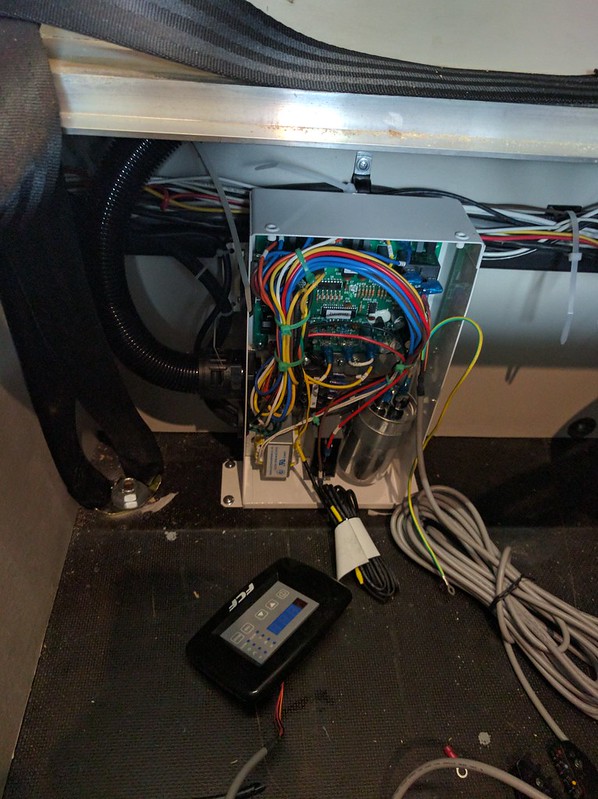

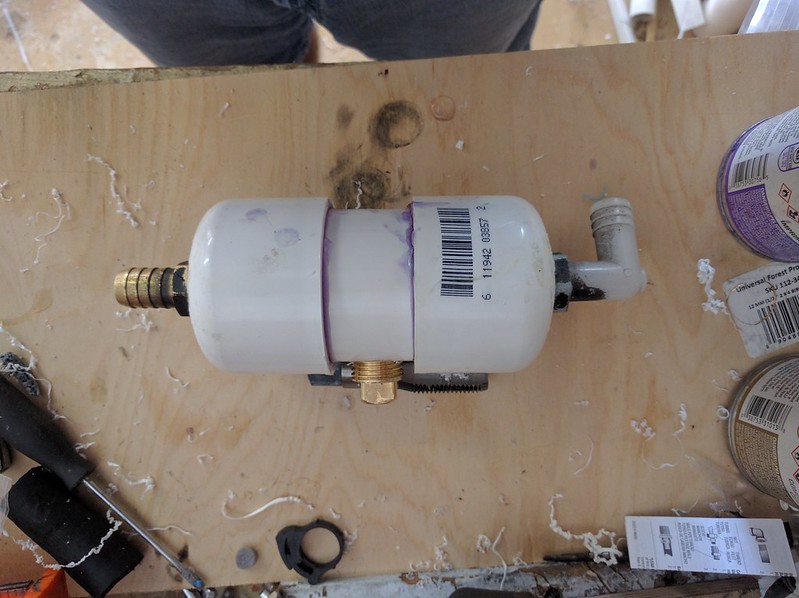

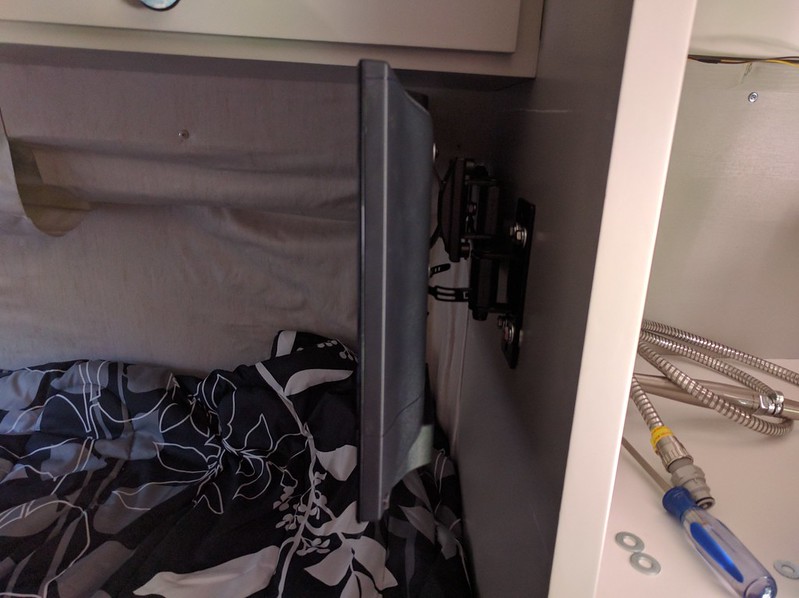

The AC unit should be arriving today. I will post some pictures of the install. I did some measuring and there are a number of places where I can fit a medium sized radiator under the van. Browsing the web shows plenty of air to water intercooler radiators for less than 200$. Some back of the envelope math indicates that a 2” thick double pass radiator with an area of 150+ square inches should be sufficient for the 2.2kW heat rejection requirements of the 5k BTU webasto unit.

A friend of mine plasma cut and bent some steel sheet for me. It will become a fairly unusually shaped fuel tank. 16 gauge would have been ideal, but beggars cannot be choosers. So I will have a 10 gauge galvanized tank welded up soon. One of the bends is off a hair, so I will need to trim one edge before assembly. This may be a challenge with my limited tools.

The tank fits in the space under the sliding door and should be around 14 gallons. I could have gotten an 19 gallon tank to fit, but the alternator charging wire interferes, and it wasn't worth the cost to make a new one.

The AC unit should be arriving today. I will post some pictures of the install. I did some measuring and there are a number of places where I can fit a medium sized radiator under the van. Browsing the web shows plenty of air to water intercooler radiators for less than 200$. Some back of the envelope math indicates that a 2” thick double pass radiator with an area of 150+ square inches should be sufficient for the 2.2kW heat rejection requirements of the 5k BTU webasto unit.

Last edited: