brentonodon

Member

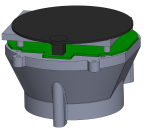

New nozzles finally arrived and I got them assembled into the housings. These old mechanical diesels are interesting beasts.

The old nozzles had worn in a really interesting pattern that I thought might have been part of the design but after comparing to the new ones it's not.

Took all the shims out and measured them. The shims help set the pressure that the injector begins to open which affects your timing. Too high and you've got a retarded injection, too low and it'll be advanced. So tonight I've gotta take each injector and throw them on the tester to see what pressure they open at. I believe that since this is a naturally aspirated 4D56 the opening pressure should be right around 125bar. When I eventually sort out the turbo I picked up for this I'll have to move that to I think 140bar.

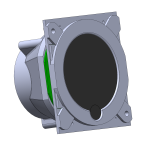

Here's the injector parts pre-assembly.

The old nozzles had worn in a really interesting pattern that I thought might have been part of the design but after comparing to the new ones it's not.

Took all the shims out and measured them. The shims help set the pressure that the injector begins to open which affects your timing. Too high and you've got a retarded injection, too low and it'll be advanced. So tonight I've gotta take each injector and throw them on the tester to see what pressure they open at. I believe that since this is a naturally aspirated 4D56 the opening pressure should be right around 125bar. When I eventually sort out the turbo I picked up for this I'll have to move that to I think 140bar.

Here's the injector parts pre-assembly.