G100

Adventurer

Rack build moving along but slowly

Thanks for all input guys, I have been working on this project a lot slower than I would like, but now I have a deadline so hopefully I will speed things up a little. I plan on going down to baja for a week at the end march and I want the rack to come with me, its going to be tough so we'll see.

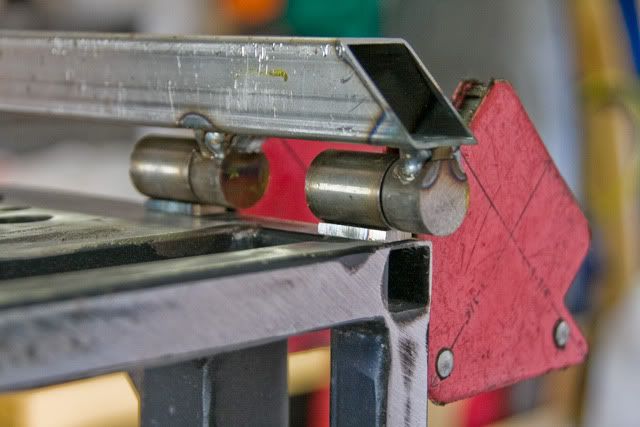

So I did end up welding on the frame bracket, it went pretty smooth, it was a difficult space to get to but I think it will hold up just fine. Here is a shot of the end result.

Getting the compound angles cut right on the uprights took some time and a lot of trial and error.

I am hoping that things should move a lot faster now that most of the cuts will be 90s or 45s.

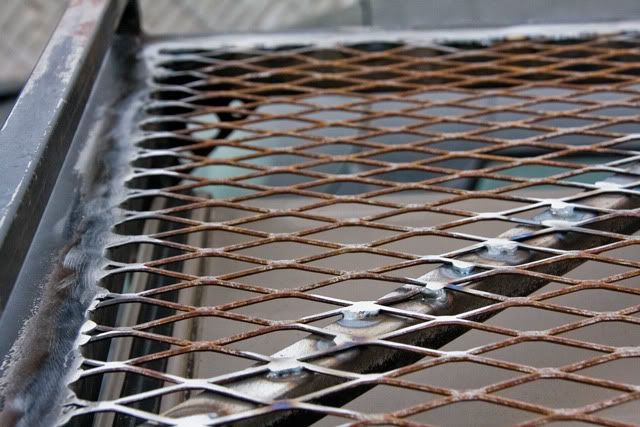

I started putting together the actual rack which felt good. I am using 16 guage 1.25" square tubing for the frame and .75" square tubing for the rails.

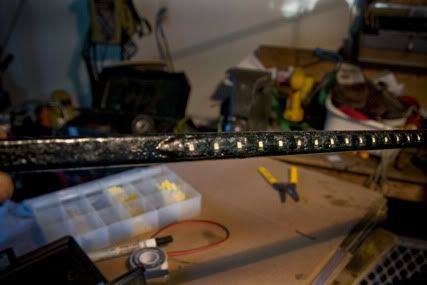

The top of the rails are going to be 2" above the 1.25" tubing. The vertical pieces of the rails are stainless steel because I will be leaving the tops open to be able to recieve 5/8" square tubing for accessories like surf racks, kayak racks and maybe even a custom roof top tent in case the family starts getting bigger.

[?????] I am trying to figure out how to make drain holes at the bottom that won't ruin my lineX coating down the line when the 1.25" tubing at the bottom starts rusting. I was thinking maybe put a stainless cap on the vertical pieces then weld it on cap side down, then once the lineX coating is on, drill a small hole. This way no rust is bubbling up the lineX, I am affraid though, it might just happen anyways because water is going to eventually seep under the coating through the seam. If you guys can actually figure out what I am talking about and have a suggestion I would love to hear it. Maybe the best option would be stainless steel, no drain hole, let it evaporate.[/?????]

I bought some Vision X LED euro lights off ebay for the front, they should be here this week, hope I made the right choice.

Thanks for all input guys, I have been working on this project a lot slower than I would like, but now I have a deadline so hopefully I will speed things up a little. I plan on going down to baja for a week at the end march and I want the rack to come with me, its going to be tough so we'll see.

So I did end up welding on the frame bracket, it went pretty smooth, it was a difficult space to get to but I think it will hold up just fine. Here is a shot of the end result.

Getting the compound angles cut right on the uprights took some time and a lot of trial and error.

I am hoping that things should move a lot faster now that most of the cuts will be 90s or 45s.

I started putting together the actual rack which felt good. I am using 16 guage 1.25" square tubing for the frame and .75" square tubing for the rails.

The top of the rails are going to be 2" above the 1.25" tubing. The vertical pieces of the rails are stainless steel because I will be leaving the tops open to be able to recieve 5/8" square tubing for accessories like surf racks, kayak racks and maybe even a custom roof top tent in case the family starts getting bigger.

[?????] I am trying to figure out how to make drain holes at the bottom that won't ruin my lineX coating down the line when the 1.25" tubing at the bottom starts rusting. I was thinking maybe put a stainless cap on the vertical pieces then weld it on cap side down, then once the lineX coating is on, drill a small hole. This way no rust is bubbling up the lineX, I am affraid though, it might just happen anyways because water is going to eventually seep under the coating through the seam. If you guys can actually figure out what I am talking about and have a suggestion I would love to hear it. Maybe the best option would be stainless steel, no drain hole, let it evaporate.[/?????]

I bought some Vision X LED euro lights off ebay for the front, they should be here this week, hope I made the right choice.