Back To Work!

Alright after a four month hiatus, its time to get some stuff done. So here is the start of my rack project that I started during my time off over the holidays. I need some opinions on some stuff also, so help me out.

Okay so to start out here is a picture of the basic plan, but of course to be improved upon.

What I want to improve/change:

-lower profile design

-air deflector in front (for MPGs) with recessed/inset lights (only 2,not 4)

-use LED light strips for side lights

First thing to get done are the vertical supports. The rear is basic, just 1" square tubing straight up from the bumper. I will be adding a tab that will come off of a little "ladder" step that will bolt in to the bed just above the tail light for more side to side support.

The front, not so basic.

Long story long: Old design has a trapazoid shaped piece resting on the bed rail under the rear window. This worked great for about 5 years, until I started noticing the floor forming cracks on both sides right next to where the bed mounts to the frame. I would weld them up and they would just crack again, so I ended up welding some plates on there. I figure the cracks are from the top heavy weight of the rack swaying side to side. I inspected this area when I had my bed off the truck during the rear window project to see if I could just weld a plate on there before I put it back on, but toyota already has a reinforcement plate there. Then I inspected how strong the back bed rail looked, not very. The back bed rail is just a bent piece of probaly 16 guage steel spot welded about every two inches to the floor to allow for drainage.

Long story short : I need to have supports coming up from the frame cause I don't think the bed is strong enough.

plus I have to create a design that has two sides that fit around my camper shell boot and then attach together.

Heres what I have come up with so far:

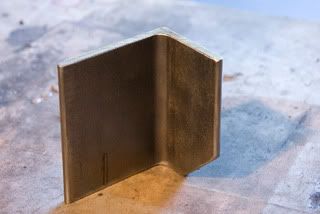

Frame brackets out of some 1/4" angle iron.

I welded a top side to the bracket so that I could have a mounting plate to take advantage of the huge unused area directly above and behind (as seen in photo above). I was thinking maybe a propane tank, possibly a battery, or maybe a water tank.

Any suggestions? it would be nice to figure out what I want to do to this, so I can plan around it.

To create the inter-locking pieces that fit together above and below my truck boot, I am going to use 1" square tubing with a piece of 3/4" square tubing that will slide inside, of course permantly attached to one side.

The connection above my boot will just slide together and attach with some bolts running down through the connection. Because I can not access the connection below my boot I will run a piece of all-thread inside the tubing. I welded some pieces of 3/4" tubing inside the 1" tubing about 4" back from the end, this is what the all thread will tighten up against.

For the supports going from the bed rail piece to the frame mounts I used 3/16" channel that measures about 2 1/2" wide by 1/2" thick which just fits perfectly in the space between my cab and bed, though I did have to grind the top a little to get it fit.

The supports come down perfectly to the where the brackets will be, and I will just bolt them in.

My question to you guys is: Do you think I should weld on my bracket or drill some holes in my frame and just bolt it on? I am leaning toward welding it on cause it seems like a bad place to be drilling two holes in my frame. It just seems like a high stress area, and I don't want to weaken the frame.

What do you think?