Making the skins for the wire frame......

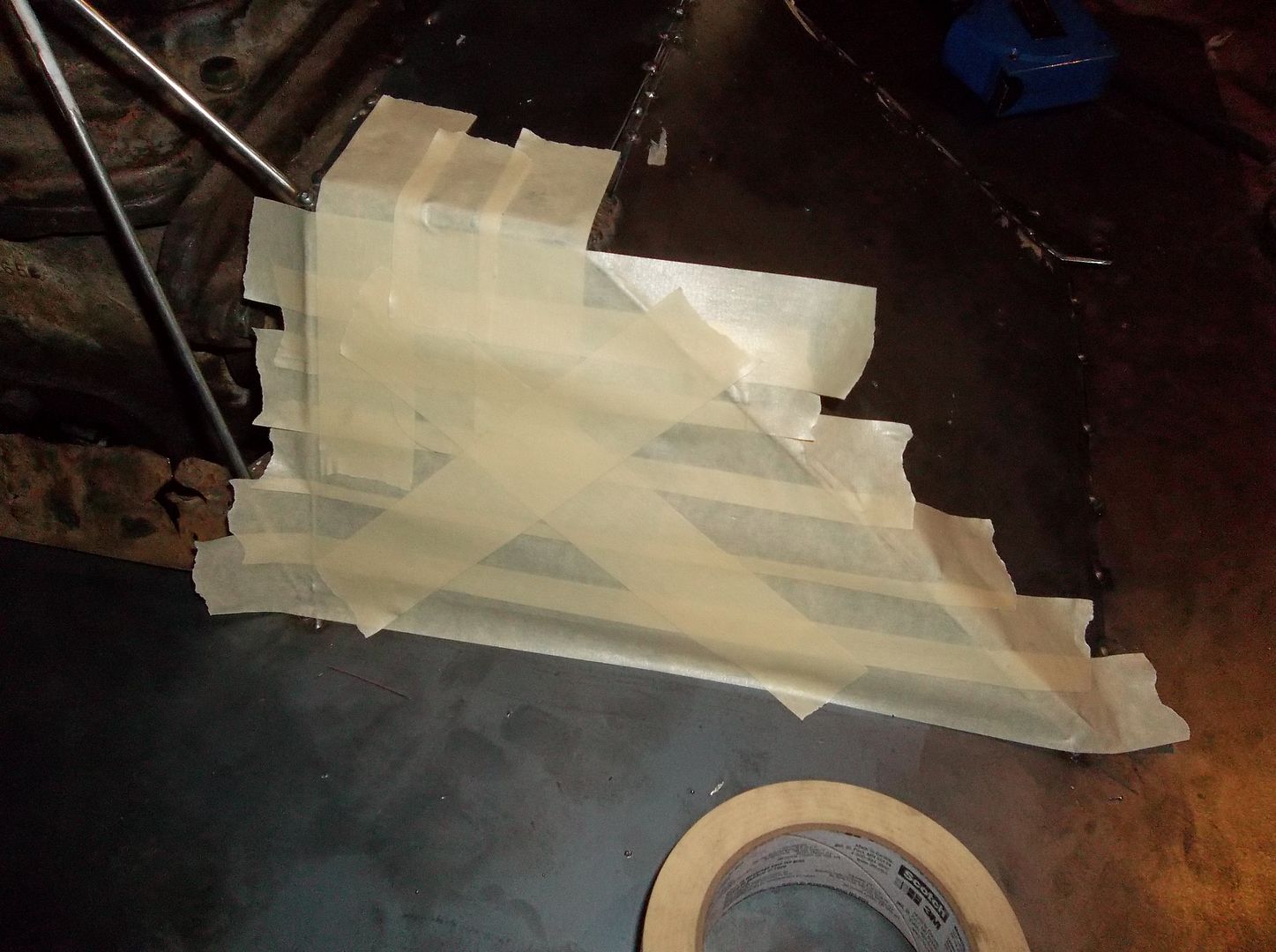

First you get some masking tape. I like the 3M basic stuff for this. It works really well.....sticky but not too sticky. Its light in color that whatever sharpy you have close at hand will show up.

Cover the area you want to skin with tape. I overlap it a big and put a few crosses in there too....

Then cut it off the frame with a box cutter or razor blade, try not to use your good pocket knife when your lose said box cutter or razor blade in the garage mess.....

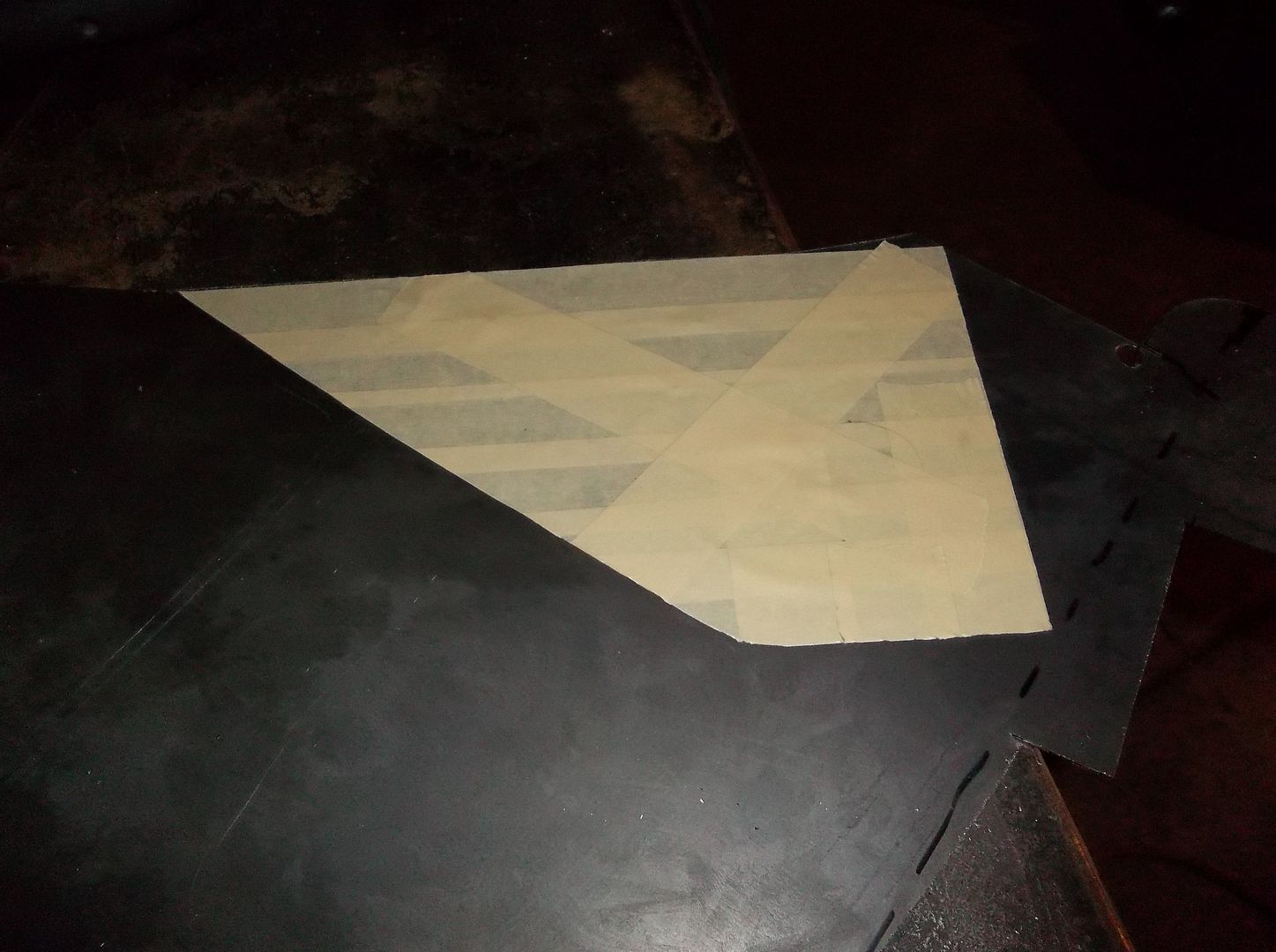

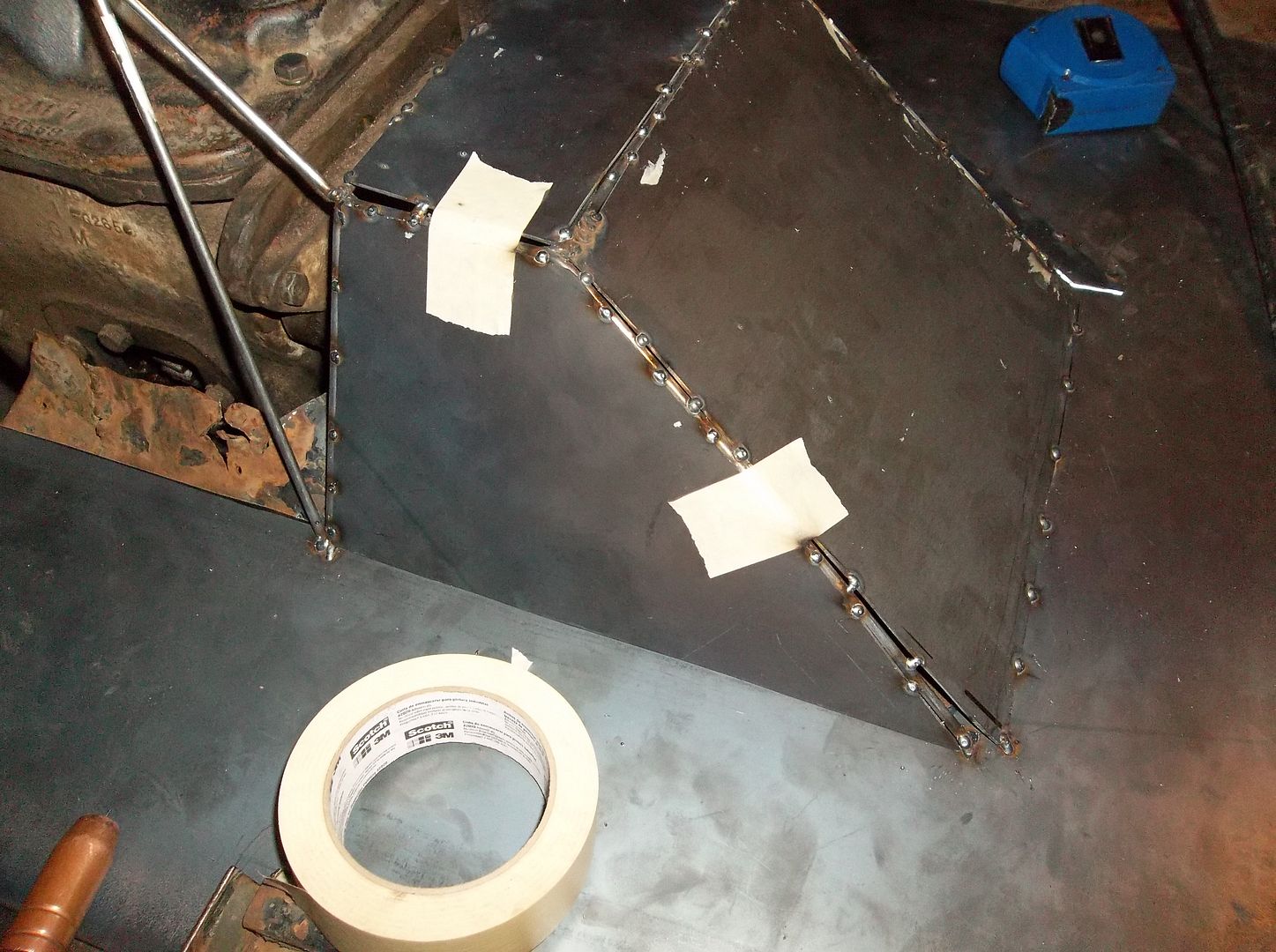

Lay the pattern sticky side down on some metal. The pattern isn't so sticky that you can't align it pretty careful. Once you have it lined up you can press it down firmly. This makes a great cut template I think. I usually cut it out with a combination of a jig saw and my band saw depending on the size of the host piece of metal. These patterns seemed to REALLY use up the smaller sections of 'waste' material.

Once its cut out I hit the edges with a worn out flap disc.....

Test fit, trim or sand the edges for clearance if needed to tune the fit. I then usually tape it in place to hold it. Then I tack weld it down. If the panel isn't totally flat you can use some pressure to slightly bend the panel for a better alignment and tack weld.

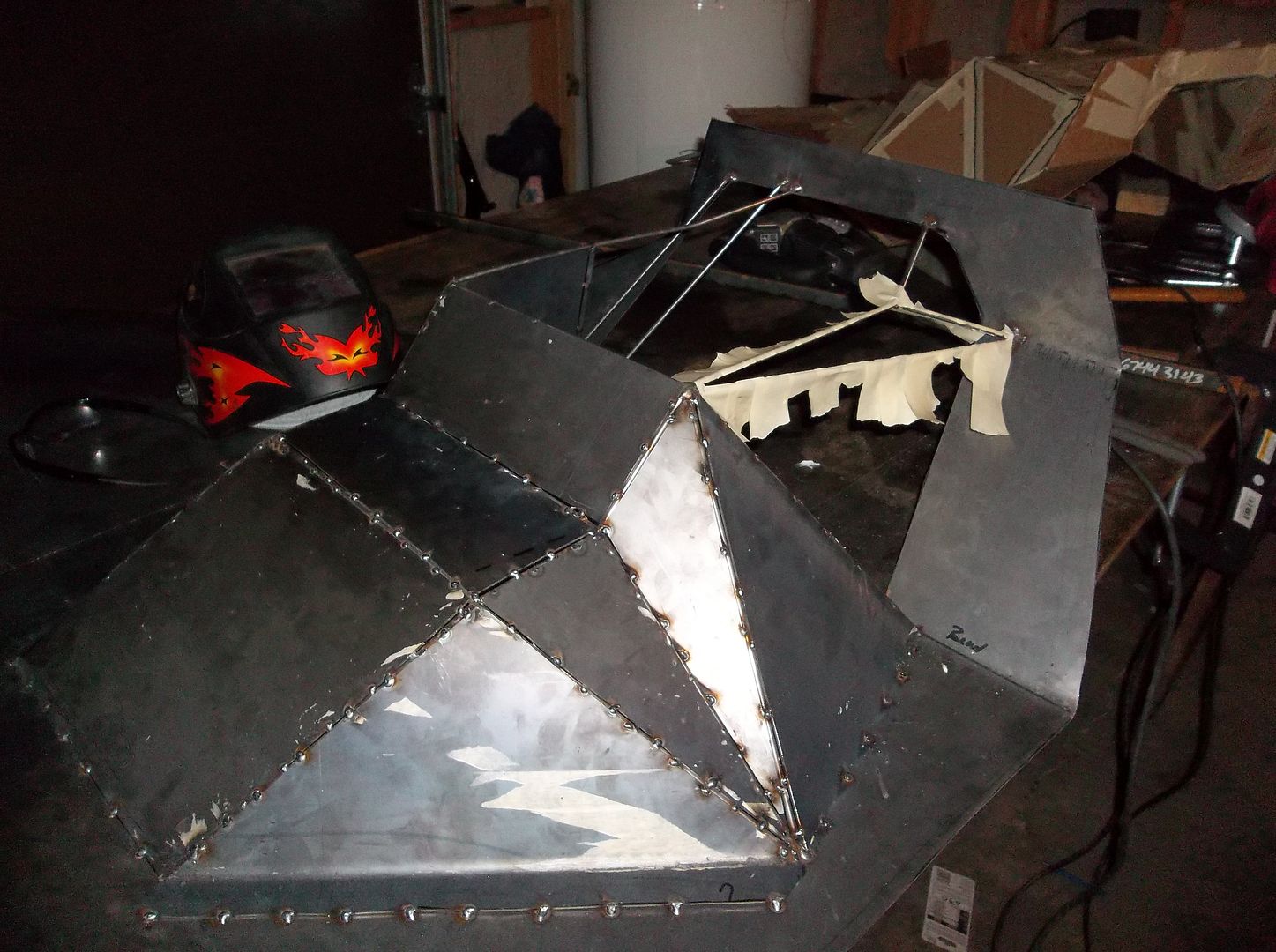

I removed the tunnel once I got to the front panels. It was just too tight to weld them in the vehicle and under the dash. The wire held everything in place pretty dang well! I was able to pull it out in once piece still!

I probably have at least another night to get it skinned. I also need to rebend the shifters before I make the final top panel. Getting it over the transfer case levers will be more challenging. I need to make a access hole for the pin that holds those shifters in place I think? That way I can remove them before I pull the tunnel off. I could also make the top panel removeable....I might to that too.