Highline front fenders part one....

Mark the grill mount location. It will be moving forward 1 3/8" when you raise the fenders along the back angled edge/mounting surface. My mounts are not welded on yet, moving them is easy. If your doing this on a factory frame you may have to make new mounts.

Mark the fender where the grill will be located. A square works well for this. Make sure this mark doesn't come off or else you are going to have to guess.

Mark the leading edge of the fender where it bolts to the grill. All this is just getting moved up, but remember the shape of the leading edge is going to change. Mark down 2.75" from the lowest bend in the grill and work from there. It takes a little thinking to figure out where its all going to end up.

The bottom mounting hole should be welded up and that mounting hole moved to just above the location of the first bend in the leading edge. Drill this mounting hole by making two holes and connecting them with a dremel cut off wheel. If you do this BEFORE you cut the fender up its a LOT easier.

Now you need to cut the leading edge out and start to rework it. A hammer and a few scraps of metal work fine, or you can use some auto body tools.

You basically need to start to reposition the lowest bend in the grill.

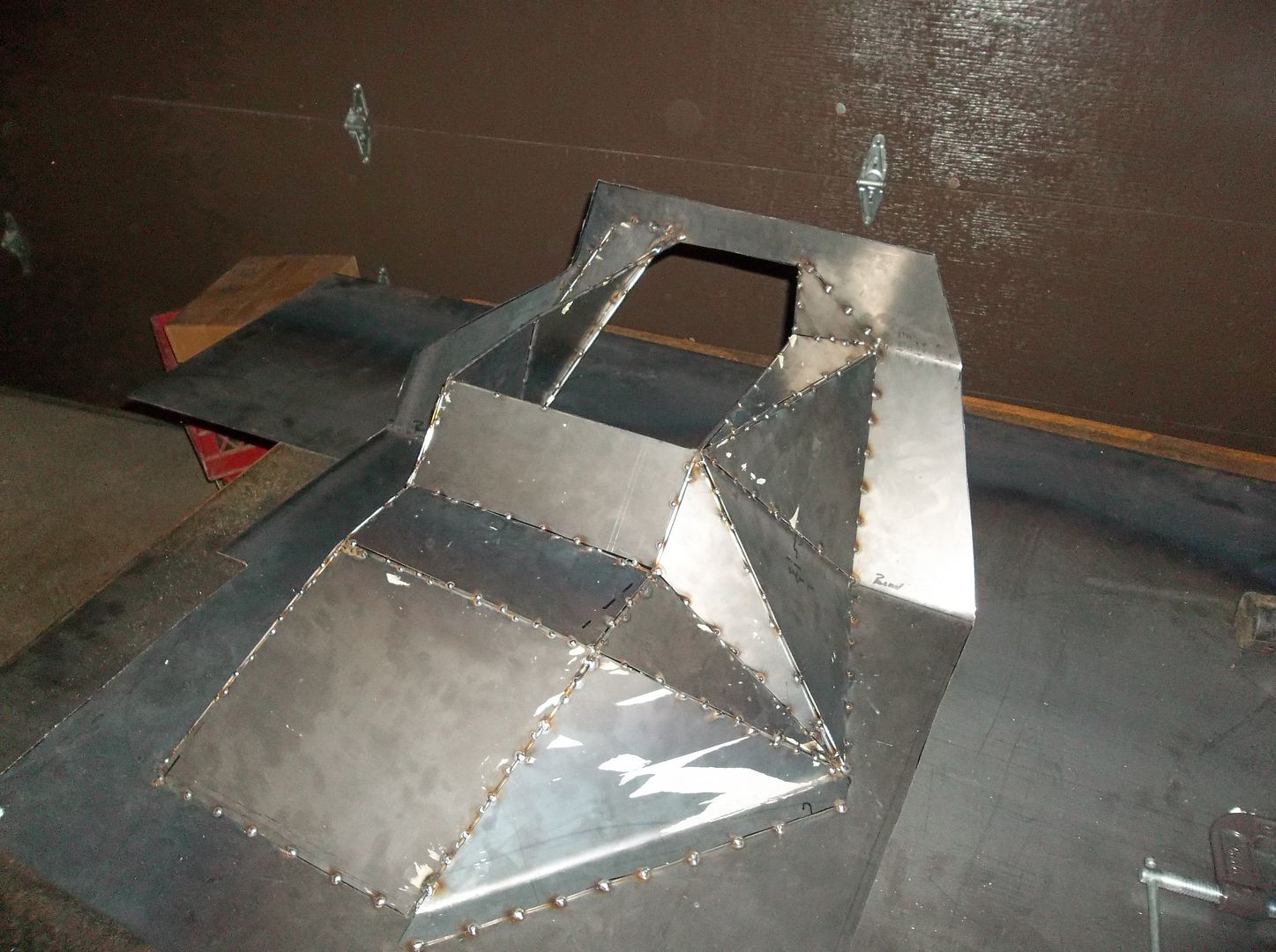

Next you need to cut out the top of the fender where it mates to the grill. This area is just too thick to reshape easily. The profile changes enough I think its going to be easier to just replace it. You can see the new leading edge starting to form. Its the same angle as the old one, jut lower on the fender.

Before you can bolt the fender back on the rear mounting holes need to be relocated 3.0" down the same plane. You only have room to move the top two bolts.

Those two holes get drilled out to 1/2" dia.

This bracket on the MB grill for the marker light needs to be cut and bend down at a 90 degree angle. Take your time. I still need to tack weld the bracket to the flange on the bottom and maybe make a little tab to make it stronger again.

Now you can bolt up your fender in its new home using the two bolts on the rear of the fender and one bolt on the grill for a test fit! Its amazing what 2.75" more clearance looks like. Remember, the grill has to be pushed forward 1.38" at this point to get things to line up!