Today was kinda lame. I got a lot done, but it just didn't go as fast as I wanted.....

I added some shiny stuff to the engine bay. This was the lowest profile setup I could find for a normal carb. The plenum will have to stick out of the hood about 1-1.5" or so. The hood is going to be trimmed to fit snugly around the plenum and part of the down tube to the air cleaner. It should end up being a fairly clean look when it's done. I didn't really want to cut the hood, but I would rather have the extra room under the belly and oil pan. Things are sure getting tight under the hood. Even with just a V6 and the grill pushed forward 1.38" there still isn't a ton of extra room!

My new 10si alternator (3-wire) also bolted right in place of the old externally regulated unit....nice! I think I will need a belt about 1" longer or so and a a connector plug for the sense and indicator wire.

I got a shock mounted.....big whoopy do! I ended up getting a 9.3" travel narrow body shock in there. With only 1" lift spring, the axle pushed forward, the narrow axles, and the big tires.....things are getting tight!

I tried not to totally destroy the inner fender. I was able to retain most of it for almost a 10" stroke shock. The other side will be much the same.

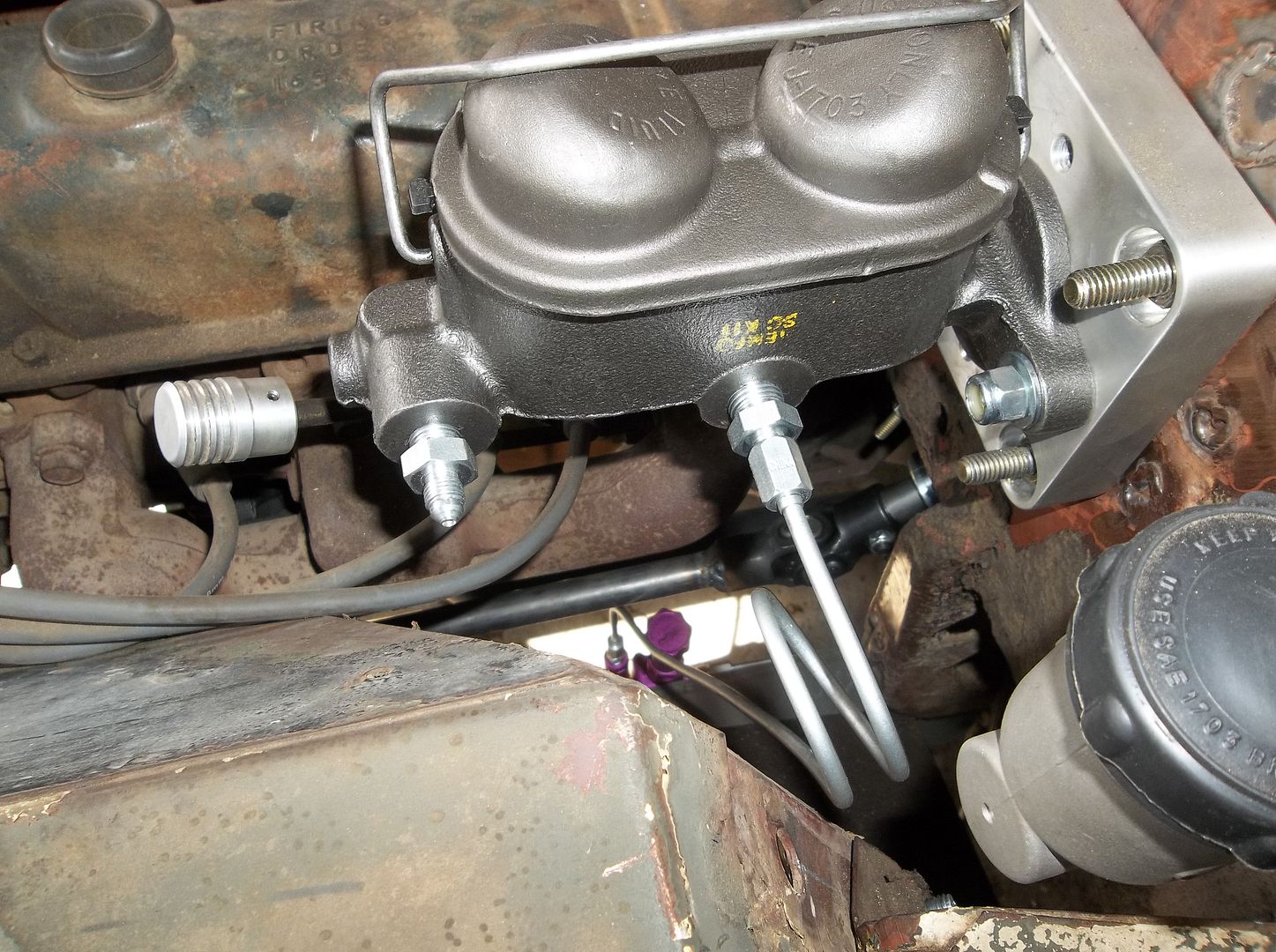

I also got the new waterjet cut brake bracket bolted on. I ended up having to make some .310 thick spacers to get the caliper mount centered over rotor with the .250 thick brackets. That was a little bit off of what my rough math predicted, but oh well. Interesting enough. Once squared up my cheapie saw is able to maintain .003-.005 on a saw cut with the set stop. Making small spacers is pretty easy and doesn't require any lathe time.....

The rear driveshaft fits! I had Tom Woods make up one of there standard 1310 shafts. The angle is just about 11-12 degrees, not great, but it will work for this old thing. The rear driveline is also just about 22" long, not bad for a flat fender!