I had a productive evening....

First I made a new fitting for my clutch master cylinder. The speedway/afco/wilwood units all come with an adapter to female 3/8 brake double flare. I purchased an adapter to go to AN-4 male from that but once I put it all together it was to long and the cluch hose ( with a 90 fitting ) ran into the firewall/cowl lip on the flat fender.......

So. After a little digging and thinking I got one of these.....

This is an Earls 963243. It is AN-4 male on one side and AN-3 male ( bulkhead ) on the other.

I had tested before ordering this fitting that the base threads on the clutch master where compatible with an-3. A normal AN-3 male fitting almost works, but its not long enough to seat at the bottom.

In comes the above fitting.....with modification....

I chucked it up in the lathe, trimmed it down, and stuck the correct 45 degree taper on the end. AN fittings are 37 degree. It ended up working sweet and saving me almost an inch in total length from the multiple adapters!

Next I decided to cut the hole in my hood for the carb plenum.....

I was scratching my head for the past few days trying to come up with a way to cleanly cut the hold in the hood......

First I threaded a misc 1/4-20 bolt into the carb. Then I used a straight edge to mark the level of the 'hood' by going from the grill to cowl.

Then I chopped the bolt down and put a rough point on it. It then was threaded into the carb so that the point sat slighty above the level of the hood by about 1/4"

Then I set the hood on and attached the latches to help hold it in position. The closer you can get the hood to its final home the better. One you get it where you want it tap the hood with a dead blow hammer over the stud location. Use light taps till you find the location and then tap is slightly harder. What you end up with is a nice little dimple in the hood giving you the location of the center of the carb......

Now take the hood back off and stick the carb plenum back on. Use a straight edge to find the distance from the carb center to the point where the air intake dips below the hood. Write this down. For me it was 11"

Find your dimple in the hood, drill it to 1/4" or so, flip the plenum upside down and bolt it to the hood. Then use a sharpie to trace the outline. Remember to keep the sharpie as perfectly upright as you can. Then remove the carb plenum and mark the distance where the air intake goes below the hood ( 11" for me ). A half roll of duct tape happened to be the right radius to connect everything on the air intake end.

Drill a pilot hole for a jigsaw blade. Then cut it out. Be careful, take your time, and don't force it through the rib on the bottom of the hood.

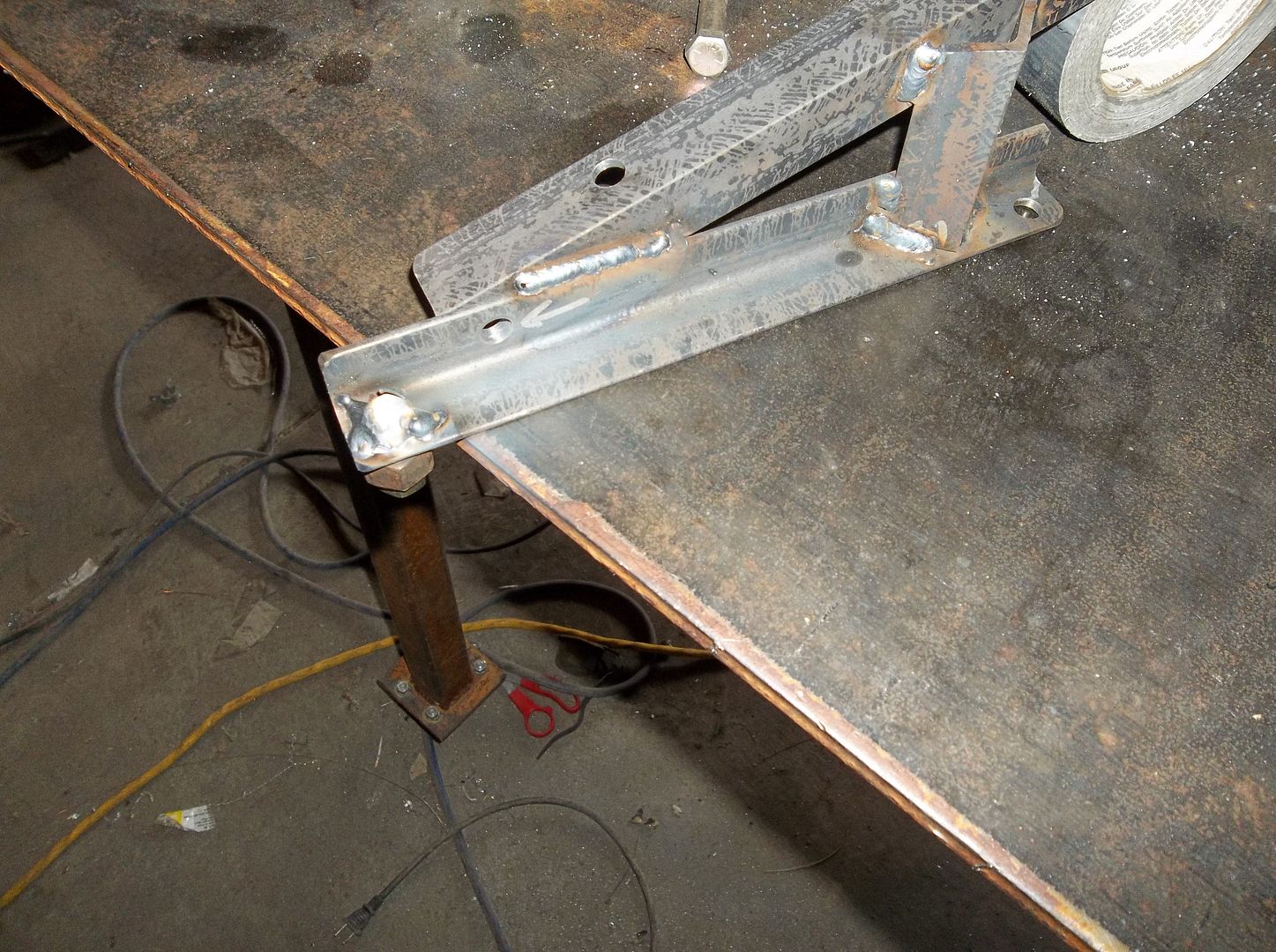

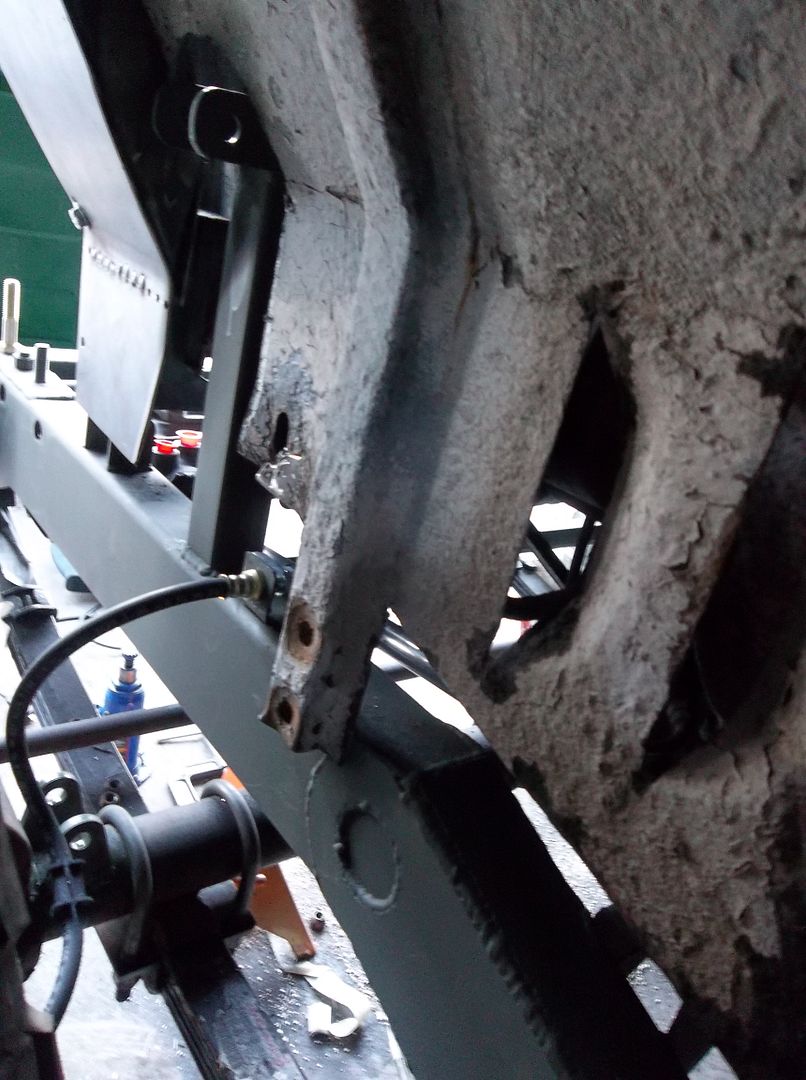

Reinstall the hood and check for fit. This was with ZERO additional trimming! I will be adding a support strip on the bottom of the hood to the drivers side of the plenum to replace the section I removed.

Not done yet, more in a few....