Metcalf

Expedition Leader

Out with the old....

Notes:

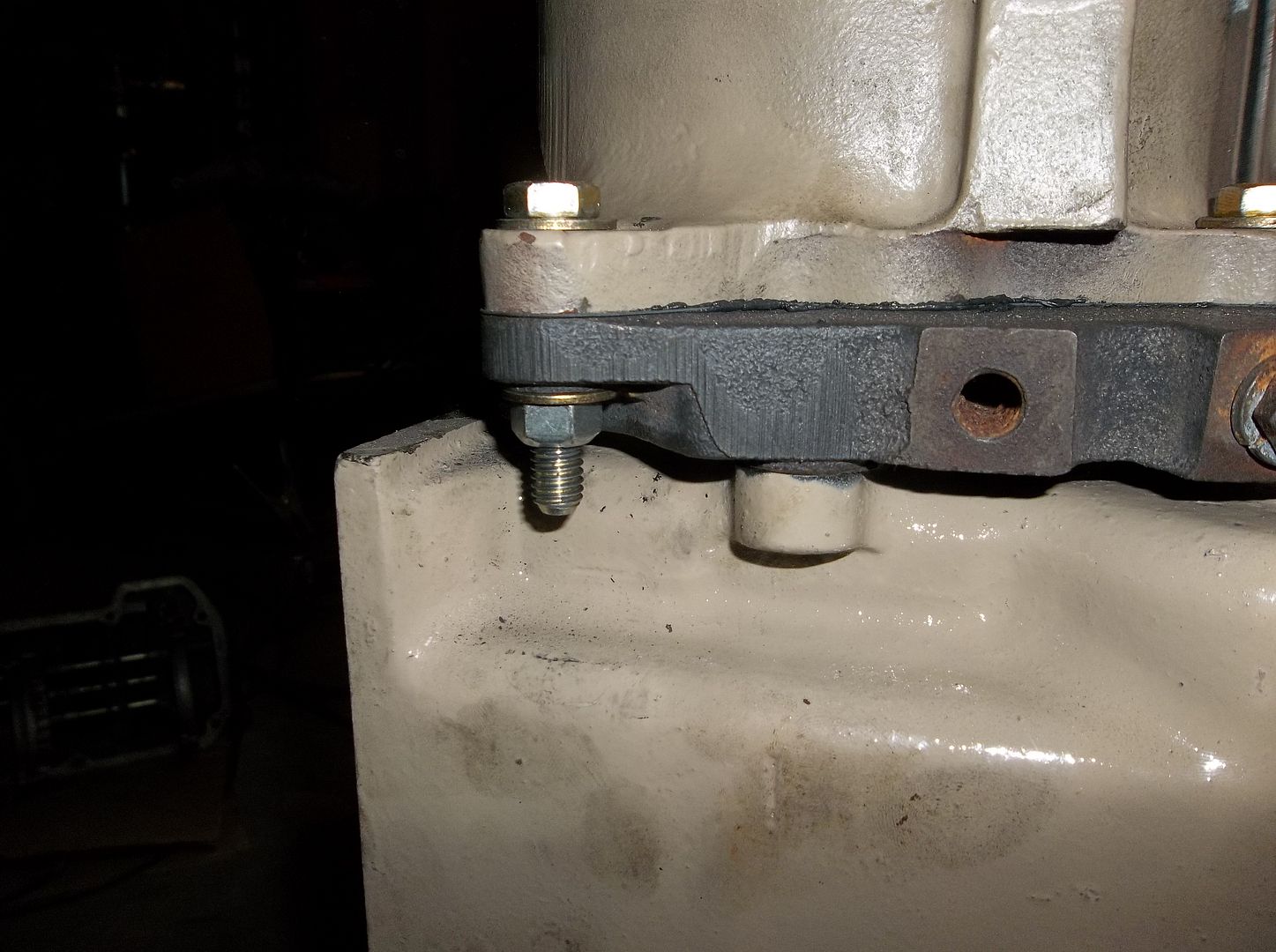

-I only had one pain in the *** mistake. I had one motor mount bolt in backwards that got trapped between the drivers side exhaust down pipe and the mount. I had to unbolt the mount from the block, and it was still a pain.

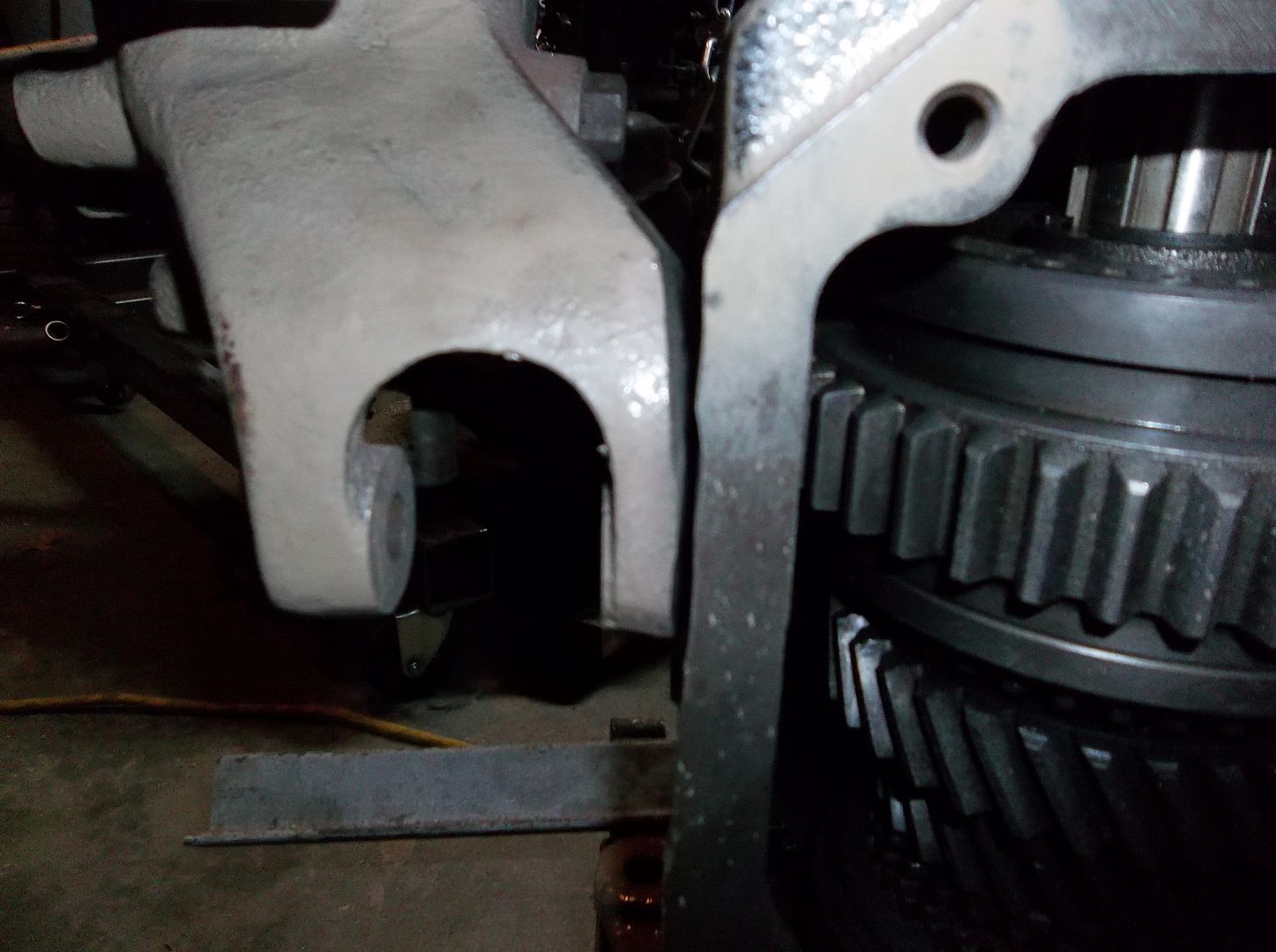

-$40 engine tilty hoist thing for the win. Best money I have spent in a LONG time. With it I was able to pull the engine, transmission, and transfer case as one unit.

-Having the Y-pipe bolted to the engine was really nice. It just comes out with the engine as a unit. A little more clearance on the drivers side would have been good.

-If I was going to do it again I would make the motor mount towers a little different for a little more room. Maybe they would unbolt from the frame for a wider space or maybe just drop out the bottom or something.

-I'm conflicted about having the tunnel welded in. Having a big hole was nice. I did have to take the top cover off also. A welded in tunnel is going to be tighter. Maybe I should just take my chances. Worst case I would have to pull the motor out the front and the transmission and transfer case out the bottom.

-Having the shock mounts a little further out would have been nice.

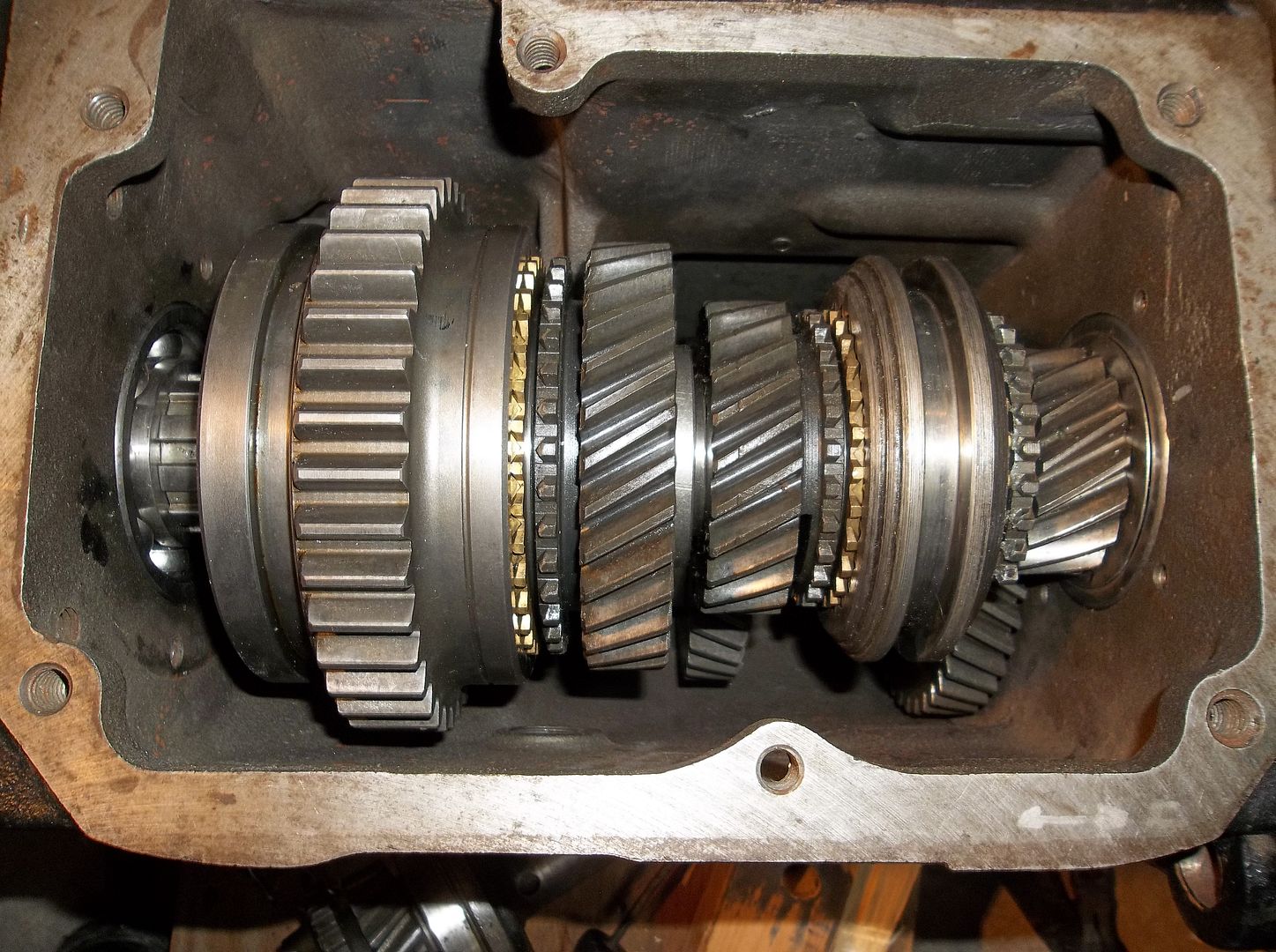

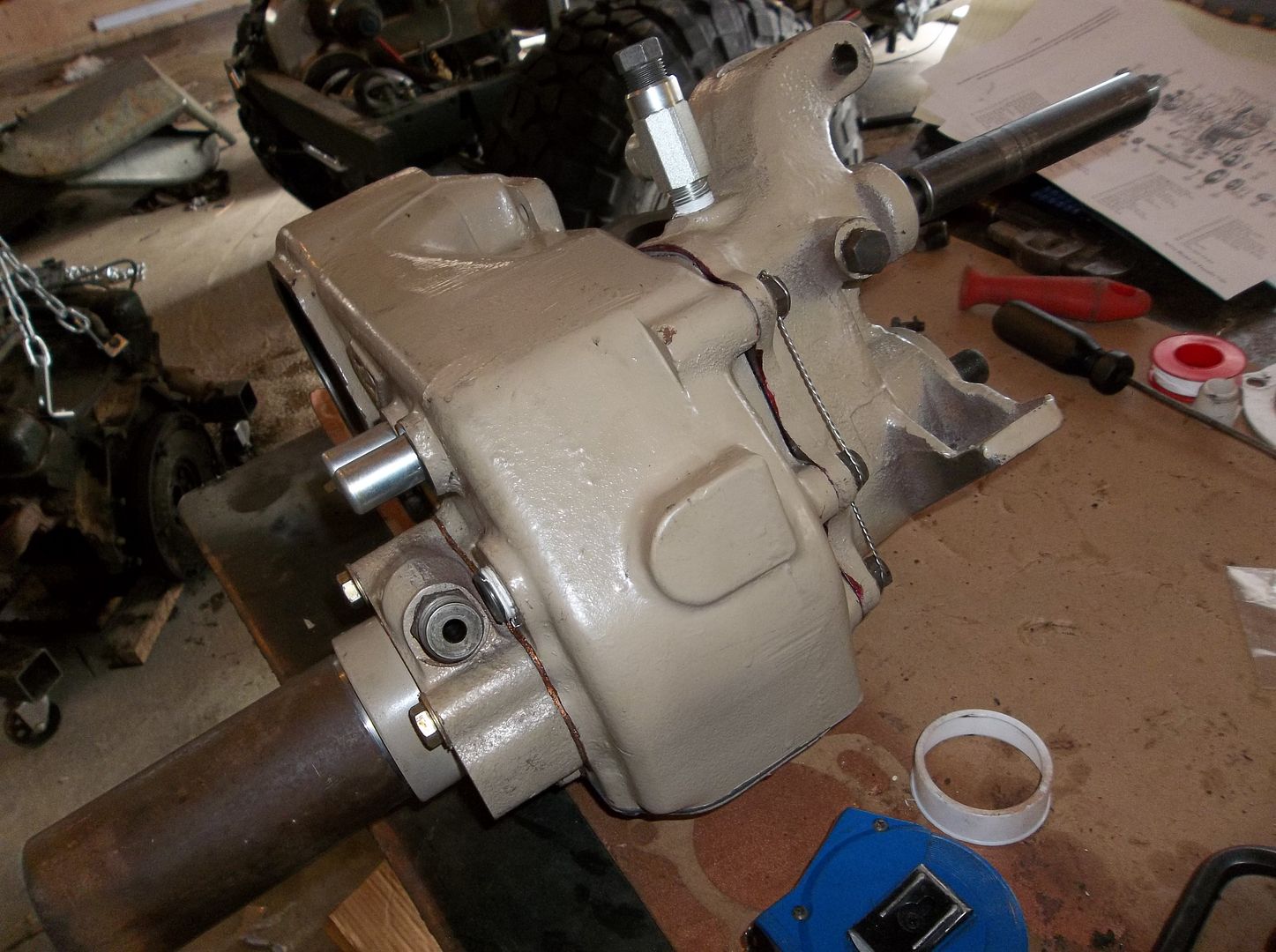

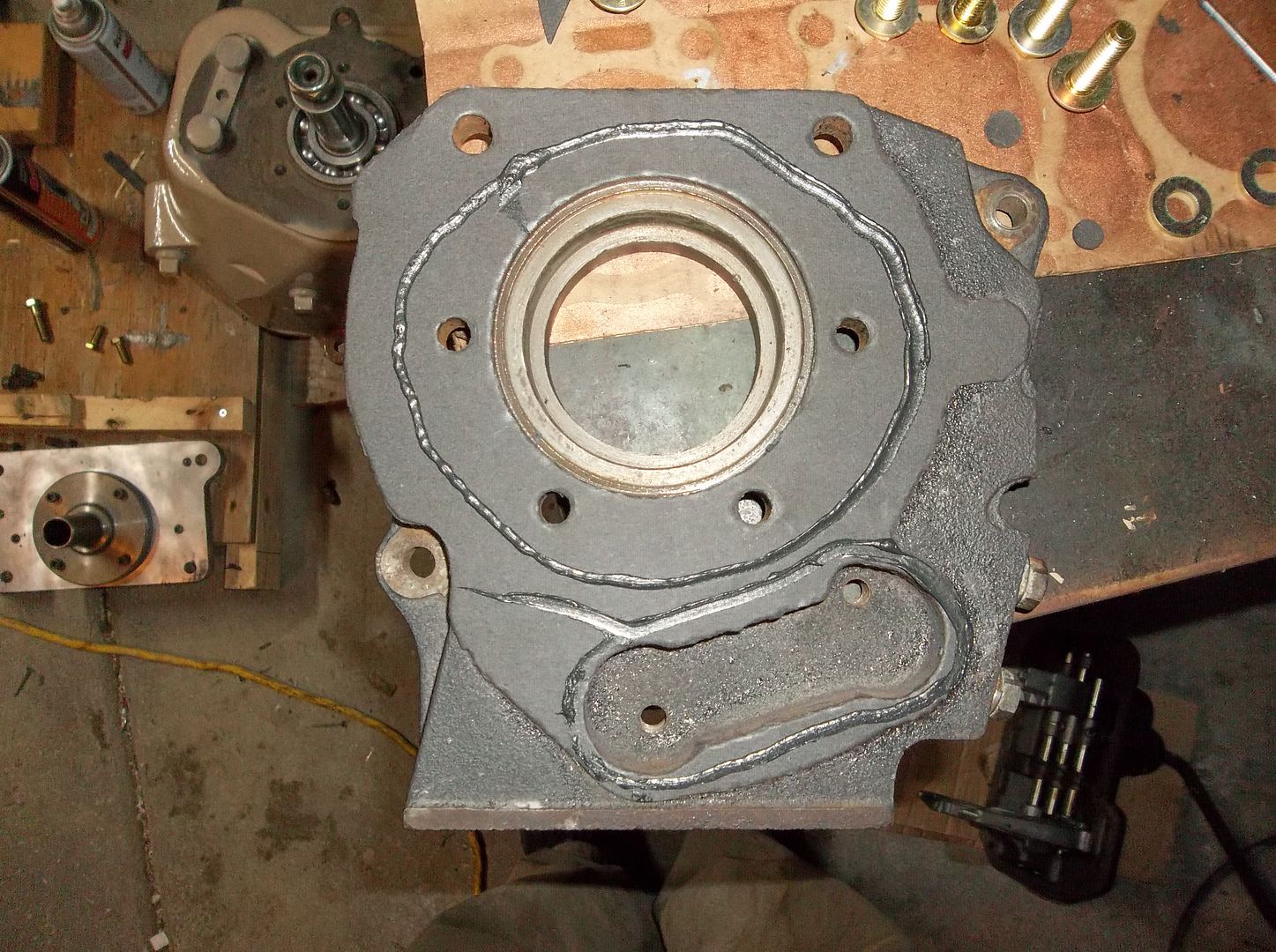

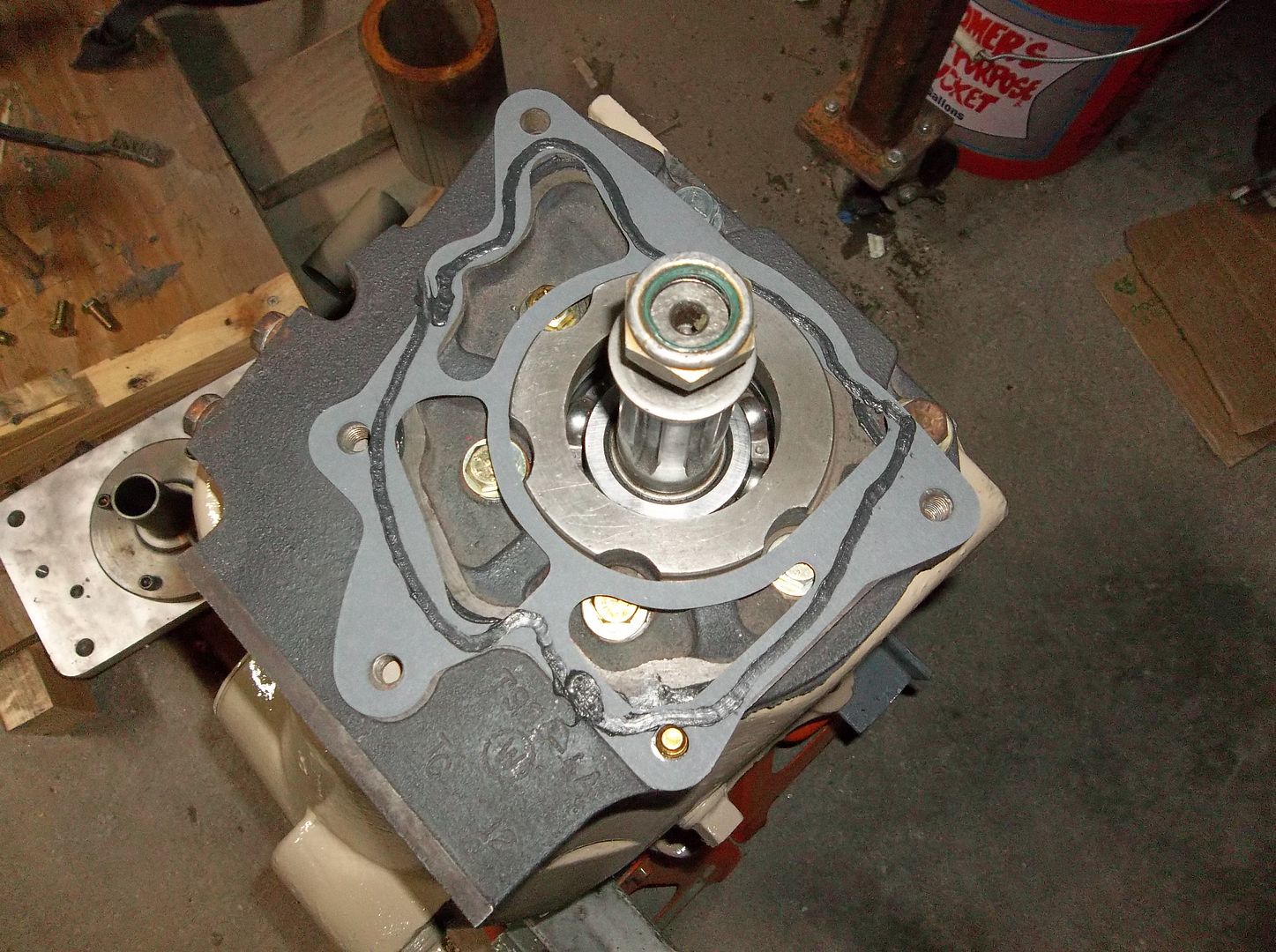

Tomorrow I will be taking off the old transmission and transfer case. I ordered all the small parts I needed to put the new transmission on the engine and finish up a bunch of little bits.

Notes:

-I only had one pain in the *** mistake. I had one motor mount bolt in backwards that got trapped between the drivers side exhaust down pipe and the mount. I had to unbolt the mount from the block, and it was still a pain.

-$40 engine tilty hoist thing for the win. Best money I have spent in a LONG time. With it I was able to pull the engine, transmission, and transfer case as one unit.

-Having the Y-pipe bolted to the engine was really nice. It just comes out with the engine as a unit. A little more clearance on the drivers side would have been good.

-If I was going to do it again I would make the motor mount towers a little different for a little more room. Maybe they would unbolt from the frame for a wider space or maybe just drop out the bottom or something.

-I'm conflicted about having the tunnel welded in. Having a big hole was nice. I did have to take the top cover off also. A welded in tunnel is going to be tighter. Maybe I should just take my chances. Worst case I would have to pull the motor out the front and the transmission and transfer case out the bottom.

-Having the shock mounts a little further out would have been nice.

Tomorrow I will be taking off the old transmission and transfer case. I ordered all the small parts I needed to put the new transmission on the engine and finish up a bunch of little bits.