Mwilliamshs

Explorer

Driveshaft length plays a large role in angularity.

that was one of my greatest concerns on my build, with the solid aam9.25 up front and no disconnect/lockouts I knew my shaft would be spinning all the time and unloaded so if there was anything it didn't like about the angles it would hum...thankfully I haven't had any of that, even at 80+ on the hwy (which I rarely do).Yeah, with the front axle disconnect, I won't have any shaft vibrations cruising in 2WD, so thats less of a concern. I just don't want annoying NVH stuff in 4hi.

IMG_20190717_164550979

IMG_20190717_164550979

IMG_20190717_173134560

IMG_20190717_173134560This circular bolt pattern is identical to that of the NP208/241

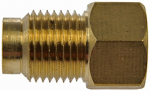

Summit Racing has about the best selection of brake fittings I've found. Be careful when ordering 7/16" brake fittings, there are a lot of 7/16-20 out there as well.Moving on to more mundane things. The sprinter uses 3/16 bubble flare. There is a union right at the subframe, so thats an easy place to connect up. It uses M10x1 nuts, which will sometimes thread into the 3/8 fittings.

View attachment 528244

The brake lines I have use 1/4" tube, with that appears to be 7/16x24 nuts. The flare is SAE double style.

Originally I was going to make a new hard line from the union to the flex line. But with them being two different sizes, I need to find a reducing union. Its turning out to be a challenge, as female-female reducing unions don't show up with a google search. I really don't want to cobble together several fittings either...

It looks like I can use dorman 785-432. It shows 7/16-24 male, which fits the GM brake line. The female side is 3/8-24. I will need to buy some 3/8-24 nuts, and 3/16 brake line. One end will be 3/8-24 SAE double flare, the other will be M10x1 DIN/Bubble/ISO flare.

Dorman Products - Aftermarket Auto Parts & OE Solutions - 785-432

Brake Line Adapter-Tube-3/16 In. x 1/4 In.www.dormanproducts.com

Looking even deeper, it looks like there are 7/16-24 nuts for 3/16" Tubing. So I think I can avoid the adapter all together.