..

CONTINUED FROM PREVIOUS POST

********************************************

5. The Ideal TerraLiner heating-incineration Air-Intake/Exhaust Vent: A Co-Axial Roof Chimney

********************************************

Of course in the case of the TerraLiner, given that it will have an incinerating toilet, a roof chimney would be strongly preferred for that reason alone. But it's interesting to learn that there are lots of additional reasons why sidewall venting in a motorhome may not be such a good idea.

Instead, the TerraLiner's ideal air-intake/exhaust format will be a "

direct power co-axial roof chimney". There are no images on Alde's website describing diagrammatically what this looks like. So I "cheated" a bit, and using

Haf-E's post which appears next, I inserted phrases like

roof co-axial Type L direct power vent chimney ,

roof co-axial direct power vent chimney ,

co-axial vent ,

L-type vent ,

type L vent ,

type L vent systems , etc. into Google image search. The key words here are "

co-axial" and "

vent", although "

Type L", "

direct", and "

chimney" may have helped -- see

http://inspectapedia.com/chimneys/Type_L_Vent_Chimneys.php ,

http://inspectapedia.com/chimneys/Direct_Vent_Chimneys.php , and

http://www.mtlfab.com/media/L-Vent_Installation_Instructions-L2147.pdf :

Also see

http://woodensun.com/showroom/what-to-bring-with-you/ ,

https://basc.pnnl.gov/resource-guides/condensing-boilers ,

http://www.slideshare.net/Wermbo/b-i-g-e-p-e-l-l-e-t-s-t-o-v-e-p1000-2009-manual ,

http://coalbasket.com/coal baskets Direct Vent.htm ,

http://www.woodstove.com/pages/pdffiles/Woodstock Gas Brch.pdf , and

http://valorfireplaces.com/media/Horizon/specs/534I Horizon Co-Axial Venting Jan-10.pdf .

There are complete Duravent catalogs of co-axial or "concentric" venting systems (pipes and chimneys), intended for use by gas or propane stoves and fireplaces, at

http://www.duravent.com/docs/product/L820_DVP_W.pdf ,

http://www.duravent.com/docs/product/directventpro_L820_2012-sep_w.pdf , and

http://www.duravent.com/docs/product/L915_W.pdf .

Note that the TerraLiner venting system could start out co-linear, and then become co-axial nearer to the chimney -- see

http://gadgetsgo.com/Z-Flex-Coaxial-Termination-indoor-tankless-hot-water-heater-ventilation.html , and

http://www.duravent.com/docs/product/directventpro_L820_2012-sep_w.pdf :

Indeed, the TerrraLiner's venting system could become co-axial

right at the chimney -- see

http://valorfireplaces.com/media/Generic Title PDF manuals/English/530_colinear_venting_Oct09.pdf and

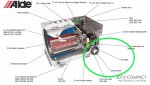

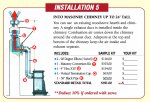

http://valorfireplaces.com/media/Generic Title PDF manuals/English/530-Colinear-Venting.pdf . In the image above I circled in green various chimneys that function simultaneously as co-axial adaptors.

This is important, because Alde's heater/boiler system will not be ideal for the TerraLiner, if only because it uses LPG. And as near as I can tell, even though Alde is a major force in the motorhome industry in Europe, and sells more heater/boilers than anyone else, all of them are LPG. Alde seems relatively uninterested in diesel, although I could be wrong about this. Hence, one cannot necessarily count on the idea that the pipe that exits the TerraLiner's heater/boiler, will be a co-axial pipe as per the Alde. It may in fact be co-linear, depending on the brand of heater/boiler used.

There is a good short article about the difference between co-axial and co-linear at

http://thehomestylecollection.com/C...ollinear-and-a-coaxial-direct-vent-system.cfm:

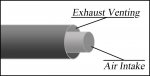

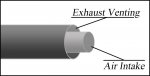

What is the difference between a collinear and a coaxial direct vent system?

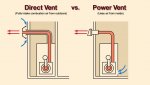

There are two types of direct vented appliances: co-linear or collinear, and co-axial. The term "direct vent" is used interchangeably between the two which sometimes adds to the confusion.

In a co-linear system, the vent and the intake liners run parallel to each other, hence the name co-linear. Co-linear systems use two continuos flexible aluminum chimney liners as the venting system. Nearly all co-linear installations occur in a masonry chimney. A bottom view of a co-linear termination is below.

In a co-axial system, the vent and intake pipe are nested into one another or share the same axis, hence the name co-axial. Co-axial systems use two rigid single wall pipes as the venting system. This configuration allows for air flow through the pipe to prevent heat transfer to the surrounding combustible structure. Unlike the continous co-liner liner, co-axial pipe is installed in sections. Most co-axial installations occur in a chase. A bottom view of a co-axial termination is below.

What's really wanted is a dual-energy, diesel/electric boiler-heater, one that heats both hydronically (for under-floor heating), as well as circulating air, as per a "forced-air" heater like the Webasto Air-top. But such a thing probably does not exist. One probably has to choose between hydronic versus forced-air circulation.

"Forced-air" is a British expression that seems very descriptive and precise, and I prefer it to "central heating", the North-American expression -- see

https://en.wikipedia.org/wiki/Forced-air and

https://en.wikipedia.org/wiki/Central_heating . Central heating can also mean hydronic, heating via the circulation of water. So "central heating" does not have the degree of precision one needs in order to talk about motorhome heating in a clear way. Now given a choice between the two, I would probably opt for "forced-air" instead of hydronic, because I would view forced-air as supplementing thin-film far-infrared panel heating, i.e. heating by electricity. As already indicated a number of times in this thread, instead of the standard kinds of hydronic radiators placed under furniture and along the walls, radiators that heat through convection (this is what Alde uses), I would like the TerraLiner to have thin-film far-infrared panels. This may even mean that under-floor heating is far-infrared/electric, and not hydronic.

Truma, Webasto, Eberspracher, etc. all make diesel heaters that come in various combinations. And Aqua Hot, the system of choice for high-end Class-A motorhomes in the United States (Newell, Liberty, Marathon, etc.) makes a heater that can use either engine heat, AC electricity, or diesel fuel -- see

http://aquahot.com/Products/RV.aspx ,

http://aquahot.com/Products/RV/675D.aspx ,

http://aquahot.com/Products/RV/600D.aspx , etc.

The Aqua Hot system seems to be only hydronic and not forced-air, whereas the Truma Combi 6 D E and the Webasto Dual Top 7 and 8 are forced-air as well as having hot-water boilers -- see

https://www.truma.com/int/en/heating/diesel-heater-combi-d-6-e.php ,

https://www.truma.com/int/en/heating/overview-truma-combi-heaters.php ,

https://www.truma.com/downloadcenter/combi_d6_e_cp_plus_ready_installation_de_gb_fr_it_nl_dk_se.pdf ,

http://www.webasto.com/int/markets-...ng-solutions/integrated-heaters/dual-top-evo/ ,

http://www.webasto.com/gb/markets-p...ng-solutions/integrated-heaters/dual-top-evo/ , and

http://www.webasto.com/fileadmin/we...ternational/rv/data-sheet/rv-dual-top-evo.pdf :

[video=youtube;SbkpWYHy7vo]https://www.youtube.com/watch?v=SbkpWYHy7vo [/video]

But whether having hot-water boilers means that these heaters could also provide under-floor hydronic heating, is an open question. As near as I can tell, the answer seems to be "no". Please correct me if I am wrong. On the other hand, for a vehicle like the TerraLiner these heaters are very interesting, because they can also heat the water in their boilers via electricity alone. In the Truma, "D" stands for Diesel, and "E" for electric; and in the Webasto range, the Dual Top 7 and 8 specifically can heat electrically. I am currently leaning towards these two heater/boilers, because they seem like they would complement far-infrared thin-film panels most successfully. But I would need to speak with a heating expert in order to nail all of this down even further.

For a

very thorough discussion of dual-energy diesel/electric heaters, and a discussion that also factors in the problem of altitude, see page 4 in the ExPo thread "

What is the BEST....High Altitude Solution for Heating?" at

http://www.expeditionportal.com/for...BEST-High-Altitude-Solution-for-Heating/page4 . It gets very technical, but has tons of links to all the relevant manufacturers and their products, including some of the more obscure ones, like

ITR, which makes military-grade heating systems that can run on a variety of fuels, including kerosene -- see post #32 at

http://www.expeditionportal.com/for...de-Solution-for-Heating?p=1598613#post1598613 .

Note that one of the main reasons why I want the TerraLiner to have electrically powered, far-infrared thin-flim heating panels, is precisely because of the altitude problem that some diesel heaters may face. Although the Truma and Webasto are diesel-electric, in electric mode they generate much less heat. So boondocking for months on the Tibetan plateau may well require that the TerraLiner have the capacity to heat its living space mostly by electricity alone. Sure, there are various "fixes" allowing one to rejigger a Webasto, Truma, or Eberspracher heater beyond its operational specifications, enabling it to work at high altitudes; fixes also discussed in the "

What is the BEST...." thread. But having far-infrared thin-film panels seems like a simpler and much more reliable solution, and would be desirable for other reasons as well. There are health benefits to far-infrared heating, and there may also be energy benefits. The South Pole traverse only uses electric heating, and so that's also something to consider.

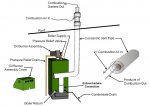

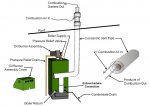

When designing the TerraLiner's combination heating system + incinerating toilet, one would then probably want their air-intakes/exhausts to fuse and culminate in a "

direct power co-axial chimney". However, a Truma, Webasto, Eberspracher, Aquahot, or ITR diesel/electric heater may not be set up to discharge and accept air to/from a co-axial pipe, as per the Alde. For instance, schematic drawings of the Truma and various Webasto products suggest that, while the Truma heater-boiler has a coaxial air-intake/exhaust, even in the Webasto Dual Top Evo the air-intake and exhaust outlet are quite separate -- see

https://www.truma.com/int/en/heating/img/combi_d_aufbau_xl.jpg ,

https://www.truma.com/downloadcenter/combi_d6_e_cpplus_ready_operating_de_gb_fr_it_nl_dk_se.pdf ,

http://www.ersatzteilbox.com/media/products/0955282001290383186.pdf ,

http://www.webasto.com/fileadmin/we...ternational/rv/data-sheet/rv-dual-top-evo.pdf , and

http://pbautoelectrics.co.uk/wp-content/uploads/2014/02/Webasto-Dualtop-EVO-Datasheet-PB.pdf :

Hence, one would want the co-linear pipes from a Webasto heater to be able to eventually fuse, and become a single co-axial chimney pipe, or chimney fixture. One would also probably need the same for the Cinderella incinerating toilet, whose air-intake and exhaust outlets are separate and co-linear, at least in the electric models (

Classic and

Comfort). Furthermore, to minimize the problem of exhaust gas from the heater venting into Cinderella toilet's combustion chamber when it's cold and not in use, one would probably want to be very careful and clever about how pipes from the Cinderella connect to the co-axial pipe that finally culminates in the roof chimney. Last but not least, one would want to locate the TerraLiner's diesel heater right beside or very near the primary 300 KW diesel generator, so that as per the Aquahot system, the TerraLiner's heating system could recover heat from the operation of the ICE-driven generator.

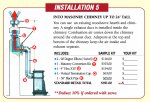

It's good to know that manufactures like Duravent exist, manufacturers who can provide co-axial pipes in a wide variety of sizes -- again see

http://duravent.com/Product.aspx?hProduct=5 ,

http://www.duravent.com/docs/product/L820_DVP_W.pdf ,

http://www.duravent.com/docs/product/directventpro_L820_2012-sep_w.pdf , and

http://www.duravent.com/docs/product/L915_W.pdf . Indeed, Duravent even produces a co-axial pipe that telescopes, with O-rings that seal off any possible exhaust leakage!!

However, my intuition tells me that the best solution for the TerraLiner will be having two co-linear hoses running up through the Pop-Up, separate hoses that only culminate in a short co-axial pipe + chimney on the roof of the TerraLiner. Further, it may even be possible that there should be four (4) hoses running through the Pop-Up, not two. On the one hand, when the incinerating toilet is going through its burn cycle, one would want it to draw in the hot air of the diesel heater's exhaust. However, if one merely had a "Y" junction much lower down in the TerraLiner from a single air-intake hose, nearer to where the incinerating toilet and heater will locate, then it seems much more likely that exhaust from the heater might "bleed" into the incinerating toilet when it's cold and not in use. The big plate in the Cinderella would be sealed, to be sure. But once one took a poop, for a brief moment when one lets the poop fall, any carbon monoxide that had collected in the toilet from the running the heater might enter the bathroom.

I don't know if "carbon monoxide bleed" or "backdraft" is a significant worry, and only fairly detailed discussion with Cabby and/or Cinderella could settle a question of this kind.

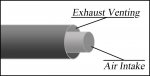

There's the added complication that one of the main advantages of co-axial pipes, is that the outer "intake" layer serves as insulation for the interior "exhaust" layer. Such pipes still need to be insulated, but less, because the inner exhaust layer is separated by fast-moving air drawn from the outside, air that is presumably cold. At least that's how Alde co-axial pipes are set up, and it's how co-axial pipes used in residential applications typically function. When renovating an old building with fragile masonry, for instance, if one wants to install a stove where before there was a fireplace and chimney, it's best to put a co-axial pipe inside the chimney. That way old masonry will be more protected from the heat. But I came across the following diagram, which seems to get things backwards:

In motorhome applications, the exhaust will most certainly be on the inside, and the air-intake on the outside.

So to add another layer of engineering intelligence (or complication), it may be best if the rigid pipes that lead vertically upwards from the incinerating toilet and the heater/boiler were co-axial in the camper box below. They would then become four co-linear flexible hoses inside the pop-up; and they would become completely co-axial again only at the final terminus on the roof, where the four hoses would merge to become a single co-axial chimney. That sounds complicated, but it's really not, because all the hardware already exists "off-the-shelf", as suggested by the images posted above, or a quick perusal through the Duravent catalogs. Including the culminating co-linear-to-co-axial roof chimney. Seems rather incredible that such stuff exists off-the-shelf, but it most certainly does.

Cleaning might be an issue. But on the other hand, a chimney broken down into "segments" that could be detached would be much easier to clean than a single unitary vent/chimney. The segments would just need to be connected in a very reliable, leak-proof way. Having flexible hoses that could detach inside the Pop-Up, for instance, would provide excellent cleaning access from above for the rigid co-axial pipes that lead down to the incinerator and heater/boiler. And the four flexible hoses could be taken outside for cleaning.

Finishing off this section, it's quite possible that Cinderella mistakenly translated the Swedish equivalent for "co-axial", as "bundled". So perhaps "

bundled roof chimney" really means "

co-axial roof chimney" -- see

http://www.hearth.com/talk/threads/cleaning-coaxial-pipe.120298/ . In any case, this seems by far the best form of venting. And if what I have written above is correct, then it will prove the most energy-efficient as well, contributing significantly to the power of the heater, and the speed of the incinerating toilet.

********************************************

6. Cabby Caravans: a well-deserved innovation prize at Düsseldorf 2013

********************************************

I am not an engineer, but when writing these posts I sure felt like one, albeit only very temporarily, using my very primitive level of pseudo-engineering reasoning. :sombrero:.. Many thanks to you both for your replies, because they sure got us thinking!! All of this also demonstrates how when exploring novel engineering solutions for an extreme-boondocking-capable motorhome, one needs to think "holistically", constantly going back and forth between systems, imagining how one system might dovetail with another. Hence, the complexity of this thread.....

Because the Cabby caravan/Cabby Loo/Cinderella Motion/Alde boiler-heater solution has become so exemplary, I now feel kind of duty-bound to insert all the images in the posting series a few pages back about the Cinderella/Cabby Loo incinerating toilet. That way others can refer to this material easily, and will know what we're talking about. What I just wrote above seems complicated to follow, even for me; even though I've been all over this material. So having Cinderella's and Cabby Loo's PDFs and images visually "ready to hand", and easily back-referenced in the course of further discussion, seems important. It's going to take a while to insert all that stuff; processing PDFs and inserting images always does.... So if the two of you respond to these three posts, as well as the one before addressed to

Haf-E -- which I hope you do! -- and if I don't respond for a while in turn, that's because I am trying to complete the Cinderella/Cabby Loo posting series by inserting all the visual material.

This discussion has become

extremely interesting. But it will only be interesting for others, beyond you two and myself, if I provide enough visual material such that others can wrap their brains around what seems to be a

very sophisticated engineering concept, developed co-operatively by Cabby caravans + Cinderella + Alde. I still don't know how Ecotech fits into all of this, but apparently Cabby caravans had help from Ecotech as well.

If I am right about all of the above, then

Wow. Cabby caravans sure came up with a very sophisticated solution, and no wonder it won the innovation prize at Düsseldorf 2013. The camper-capable "Motion" version of Cinderella's incinerating toilet then seems to be only one part of the solution. The "

bundled winter chimney" shared with an Alde heater/boiler is also important, and perhaps contributes significantly to the efficiency of the whole system? For instance, when the incinerating toilet is running,

its exhaust might in turn contribute to the heat of the intake-air used by the Cabby caravan's Alde boiler/heater. Thereby improving the efficiency of the boiler/heater even further?

What do you guys think?

The reason the Cabby Loo is so interesting, needless to say, is because it seems to be a rather unique example of an incinerating toilet used in a mass-production caravan. So far, it seems that incinerating toilets have only been installed in custom/bespoke motorhomes like the Maxi-mog and the Kiravan, or used in exotic applications like the sled-mounted living module on the South Pole traverse. Whereas the Cabby Loo seems to be the first example of an incinerating toilet developed for more widespread motorhome usage.

Here it's worth repeating that the toilet installed on the South Pole traverse is an Incinolet, and the end-users hate it. They despise the toilet, and needed to come up with special solutions to deal with the smell, like pooping in a plastic bag within one hour of using the kitchen:

Any similar concerns regarding your living/sleeping quarters? Or have you gone deliberately "all-electric" to avoid such worries about carbon monoxide, and because you have two big 50 KW generator available?

Everything besides the stove is electric- it's easier to maintain. Each room also has an escape hatch in the roof that we can crack for fresh air if needed. When designing the new modules we put the Incinolet inside the same module as the kitchen. This was a mistake. In the morning all 10 people use the crapatorium and that thing gets FULL. When we shut the generator off the fan no longer pulls the poop smoke out the vent and the foul stench starts leaking into the kitchen area. That smell doesn't make eating fun. So now we have to crap in a plastic bag if we are within an hour of shutting off the generator. That's not fun either.

See posts #53 to #58 in

Camper Thermal Engineering, at

http://www.expeditionportal.com/for...Arctic-Antarctica-Tibet?p=1655502#post1655502 and following.

By way of contrast, the Cabby Loo seems to be an incinerating toilet that actually works. Here "works" means what

Compostera means by the term: an alternative toilet that is successful on all fronts, aesthetically, psychologically, environmentally, and ethically. The Cinderella seems to be very popular in Scandinavia, and seems to receive glowing reviews on Scandinavian discussion forums -- see posts #2431 to #2434, at

http://www.expeditionportal.com/for...w-6x6-Hybrid-Drivetrain?p=2015800#post2015800 and following . It would then be interesting to find some web-discussions of the Cabby Loo specifically, and determine whether Scandinavian end-users think it is a success as well. That would be the next step in research. But as just remarked, first I first need to insert all the visual material in the Cinderella/Cabby Loo posting series.

All best wishes,

Biotect

PS --

Haf-E, you may have missed this in my reply to

Silverado; so because you have a particular interest in toilet technology, thought I'd repost.

In the course of more research, I chanced upon what is probably the most comprehensive survey yet produced of literally every experimental, alternative, or "eco" toilet design that has been proposed in recent years. See the PDF at

http://wedc.lboro.ac.uk/resources/books/Contemporary_Toilet_Designs.pdf. It must have been an expensive document to create, because it contains at least 50 custom-drawn explanatory diagrams of the toilets. These are not just lifted from manufacturer product literature, but were custom-commissioned for this survey. Perhaps paid for by the Bill & Melinda Gates foundation? Again, merely as a piece of graphic design the document looks expensive because it's so beautiful, the layout is first-rate, and the explanatory diagrams cohere. But perhaps the expense was worth it, because the diagrams are

very easy to understand.

This is a document that someone like you should have, because you will be able to digest it at deep level, and then draw interesting further conclusions. Conclusions, of course, that you would be most welcome to post in this thread....:sombrero:

..