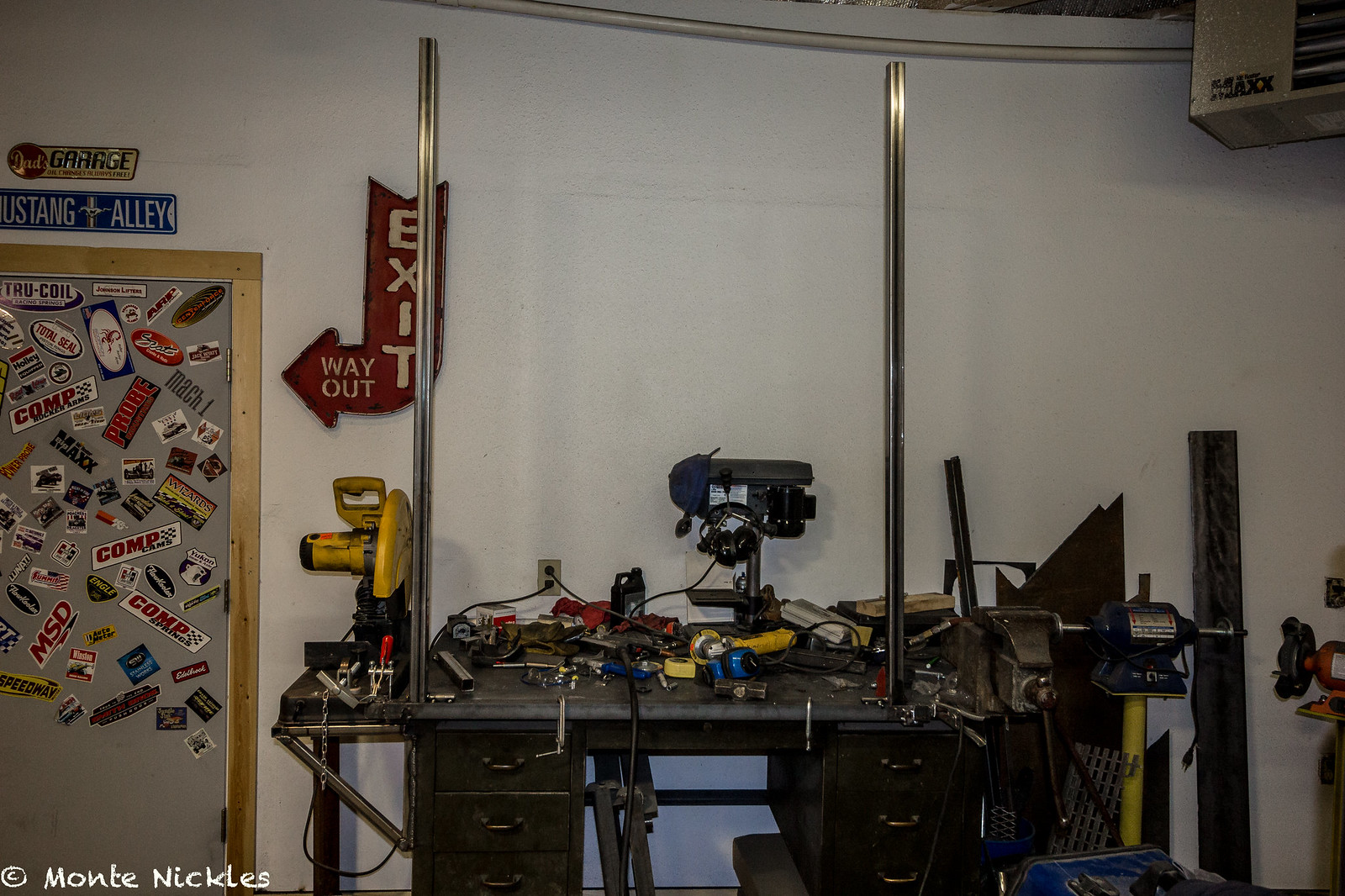

So this isn't much of a "write up" like i normally do. Mostly because..well..i hadn't planned on it at all ha. But since Mike took enough photos figured id mention it and show it off

cause...damn..it turned out awesome! I do have to apologize though. I do NOT have near as many photos as my usual write ups do for the detail. But you'll all live.

Basically, this is the rear bumper that I made. I can't take 100% credit as my very good friend Jon came and helped a lot. While it is almost all my design, he did a lot of the welding, and I did the details and cleaning haha Either way, this HurrDurr and FrankenFab collaboration turned out ************* bitchen

Like i didn't want to give it away cool. But i did.

Too start, Mike had expressed how he wanted a new rear bumper. Mostly after staring at Frankenstein's *** so much he wanted the swingout and “kitchen” setup. I agreed to give it ago and we hammered out some details.

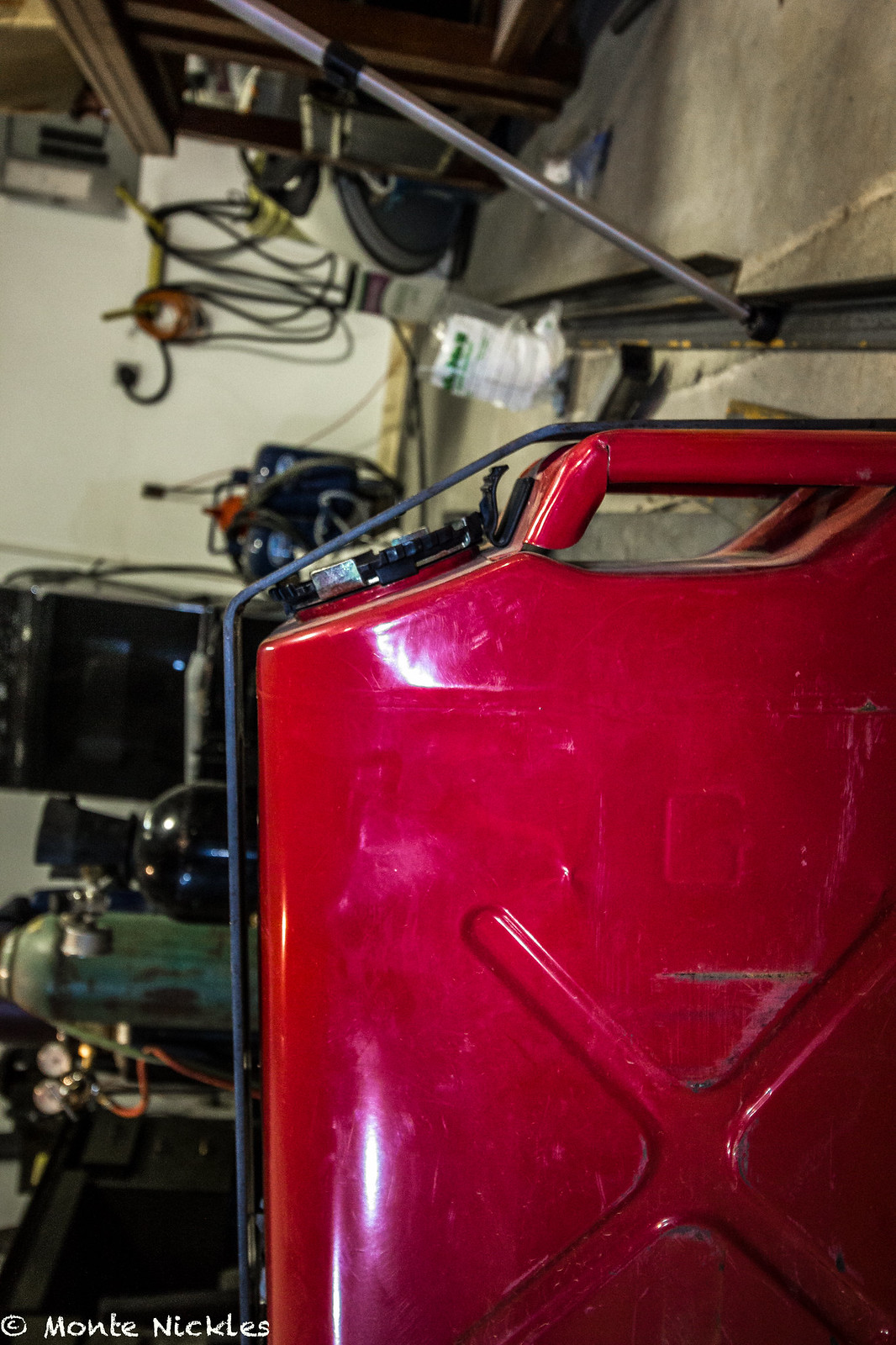

- Mike wanted a swing out with a tire mount and two jerry cans as well as the folding table and possibly the HiLift jack on it too.

- Mike wanted it slimmer then the Badlands bumper he had on it.

- Plate design of some sort, but a hybrid would be fine

- wrap around protection

- reverse lights

- built in 2'' receiver

- Tire couldn't be very high

- License plate mount

Then there where my requirements

- Be strong. Very strong

- Look damn good while being strong

- Beef as ****

- Be very slim and tight to the body

- 3/16'' plate and ¼'' plate all around

- Beef as ****

- Be stronger then my Elite bumper and better designed

- Have a camp light

- Beef...as..****

So. Pretty standard to do list for a bumper build. So I got busy with coming up with how to make it all happen with the tools and time I had. Of course my time line ended up being VERY far off, but whatever.

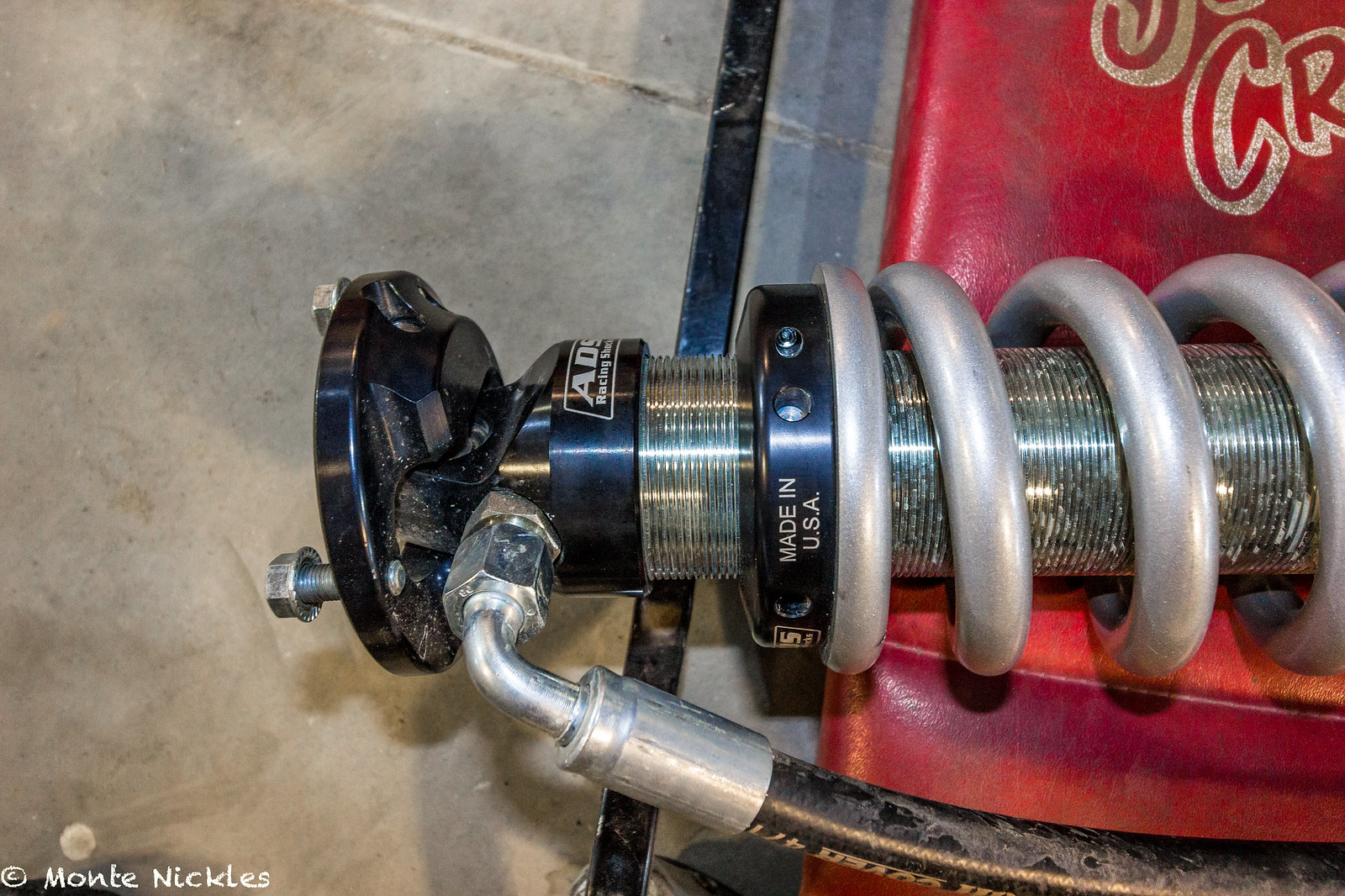

I'd be lying if I said I didn't base a lot of my design off of my own Elite rear bumper. Because, come on. It is like one of the best looking a functional bumpers ever made IMO. And seeing as to how Tim is MIA and no longer making them. They are even cooler. But there were many weakness's in mine that I wanted to address, mostly with the swingout and spindle setup.

Here is the original bumper that Mike had. Badlands built! Really its a strong bumper and has served him very well. Ben now has it on his rig. But after looking at it more..it hangs very low. The 2'' lower pipe is completely under the truck a good .5''. So 2.5'' below the body. No wonder he drug it over everything..

SOS extras-9.jpg

SOS extras-9.jpg by

Monte Nickles Photos, on Flickr

IMG_3208.jpg

IMG_3208.jpg by

Monte Nickles Photos, on Flickr

IMG_8904

IMG_8904 by

digirat99, on Flickr

Plenty of room for improvement.

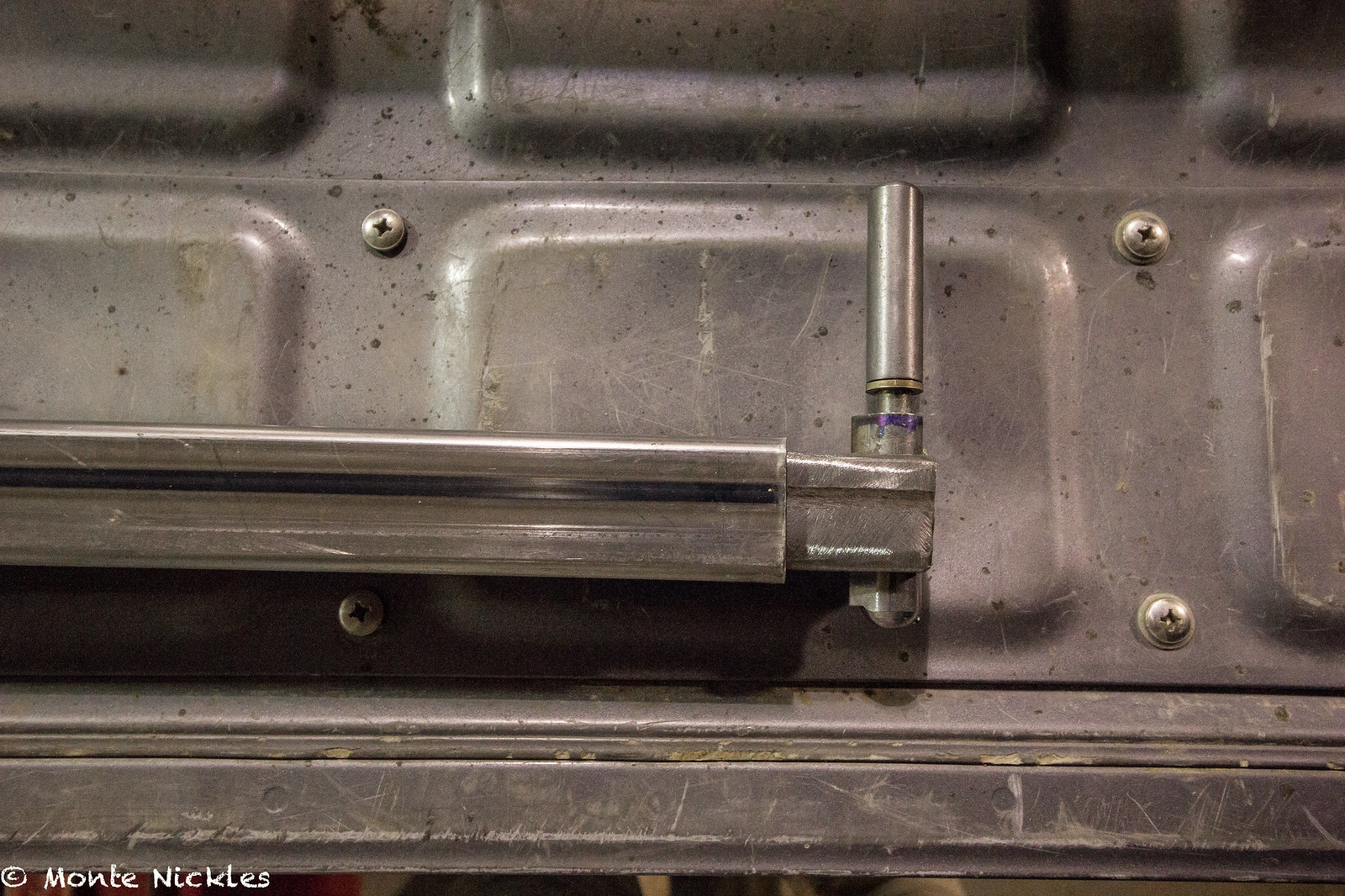

However knowing I didn't have a CAD and laser cutter or anything super fancy to make the super pretty but small beveled edges, I did what most do and bought some tubing. But I bought much bigger then most buy. Most guys that do DIY bumpers go with the classic 5''x3'' square tubing. I went for 6''x3''.

I then cut it half along the edge to make two pieces that where L shaped for the main section. Cut out holes for the reverse lights and the 2'' receiver.

IMG_8907

IMG_8907 by

digirat99, on Flickr

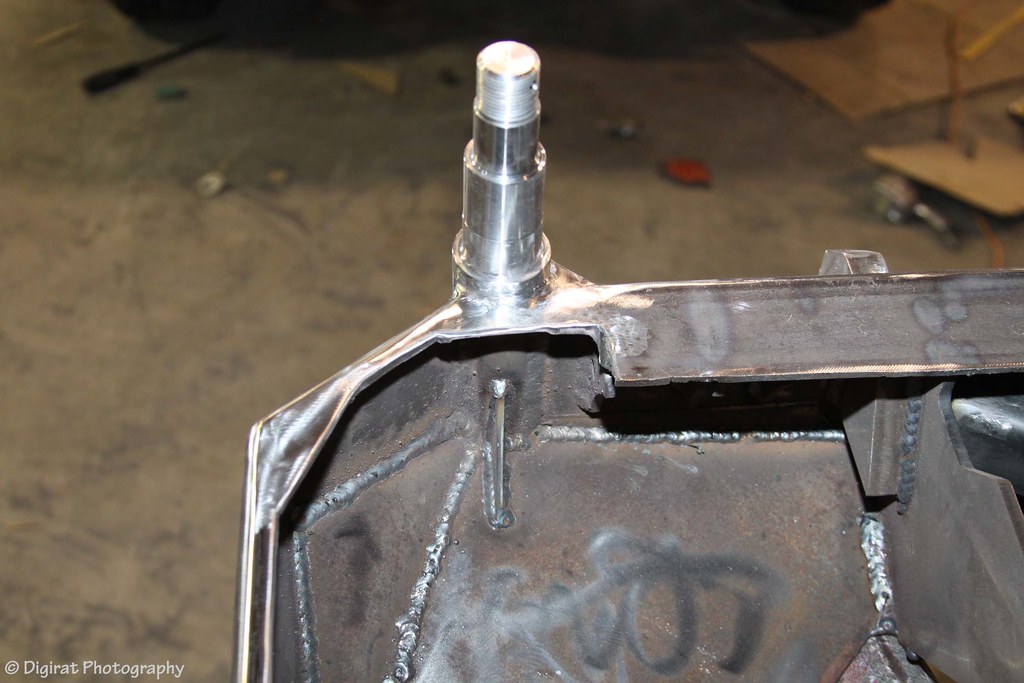

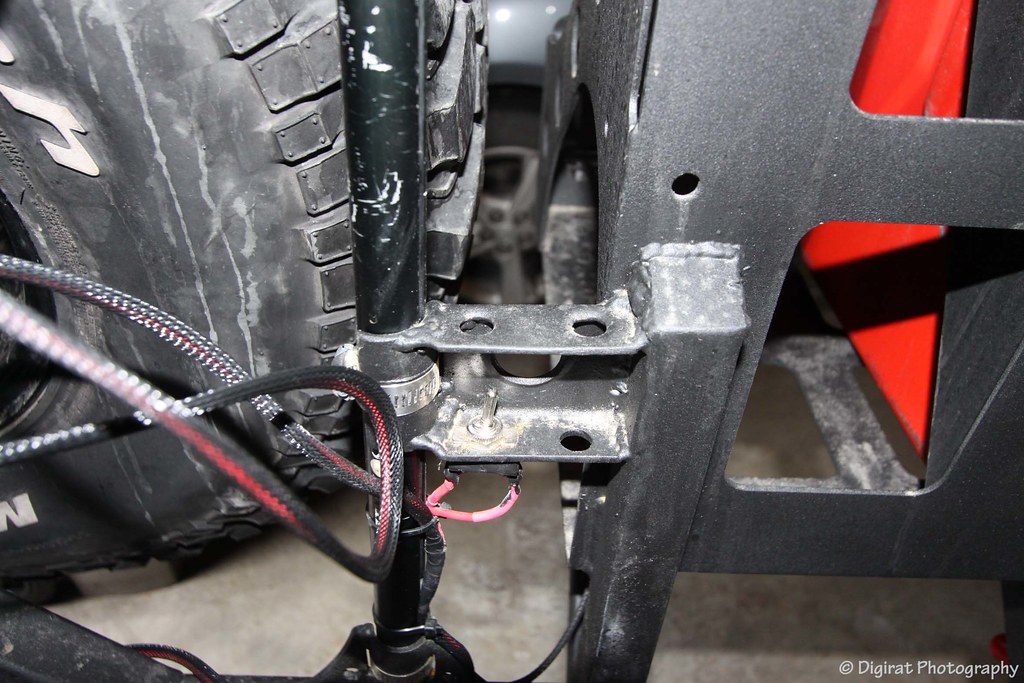

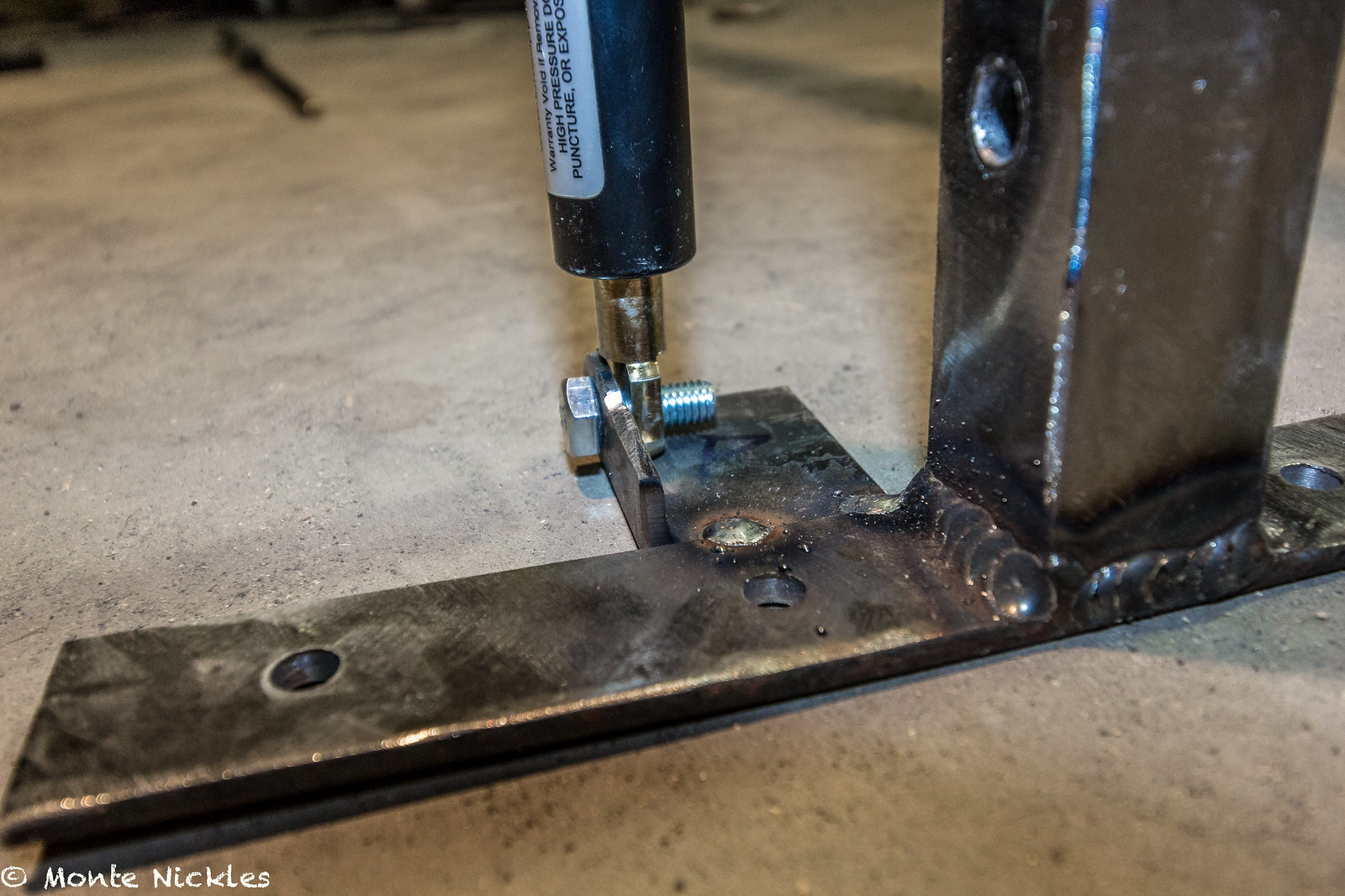

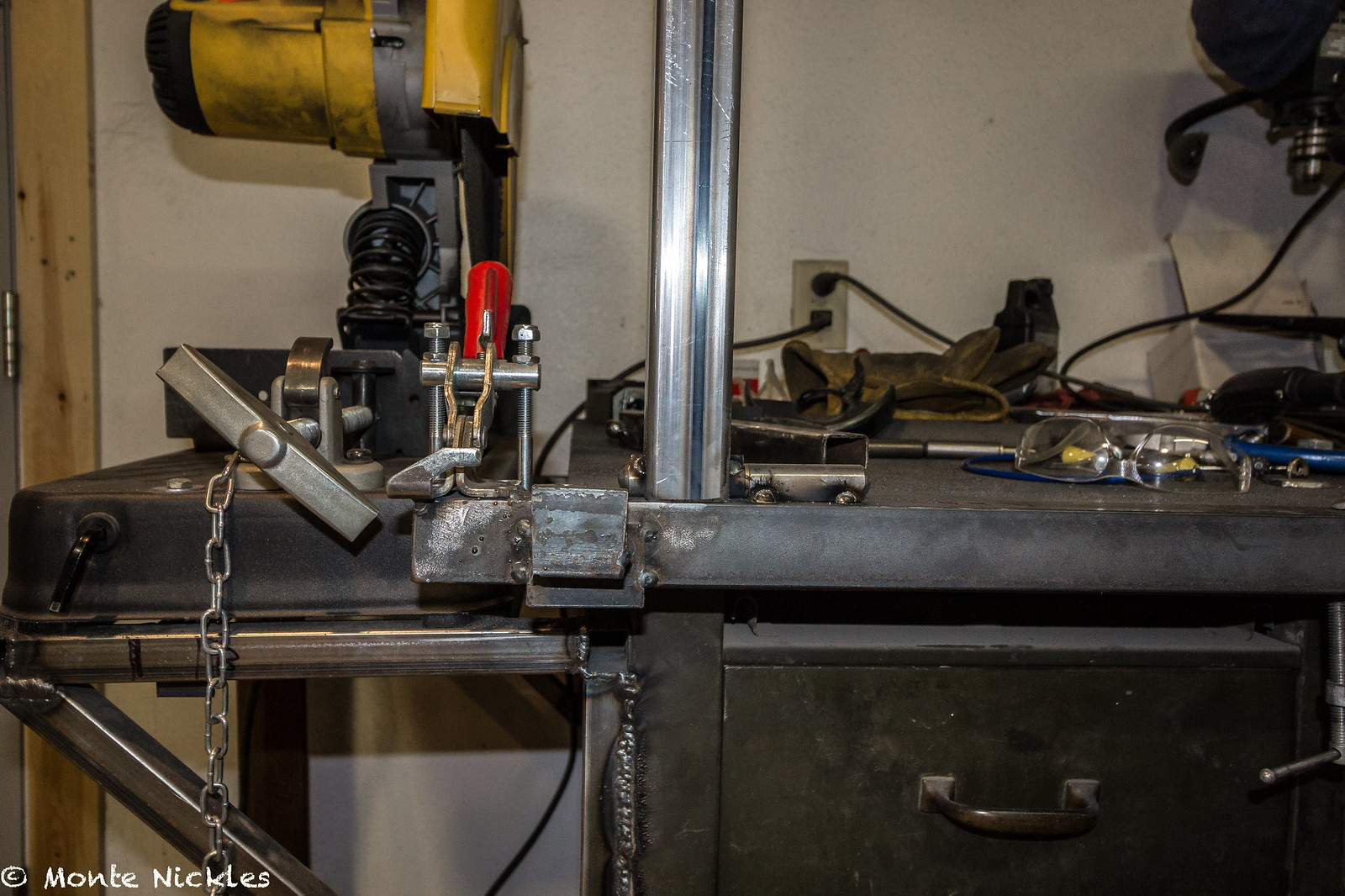

To mount the bumper I bought brackets made by Eric at Relentless Fab in his DIY section. I bought the spindle and tire mount and lights from him too. The brackets where well made. But, I did not like them for my own design. They stuck out too far and too high. So they where modified. I cut a lot off, about 2'' I think to really suck the bumper up to the truck.

IMG_8915

IMG_8915 by

digirat99, on Flickr

IMG_8920

IMG_8920 by

digirat99, on Flickr

IMG_8922

IMG_8922 by

digirat99, on Flickr

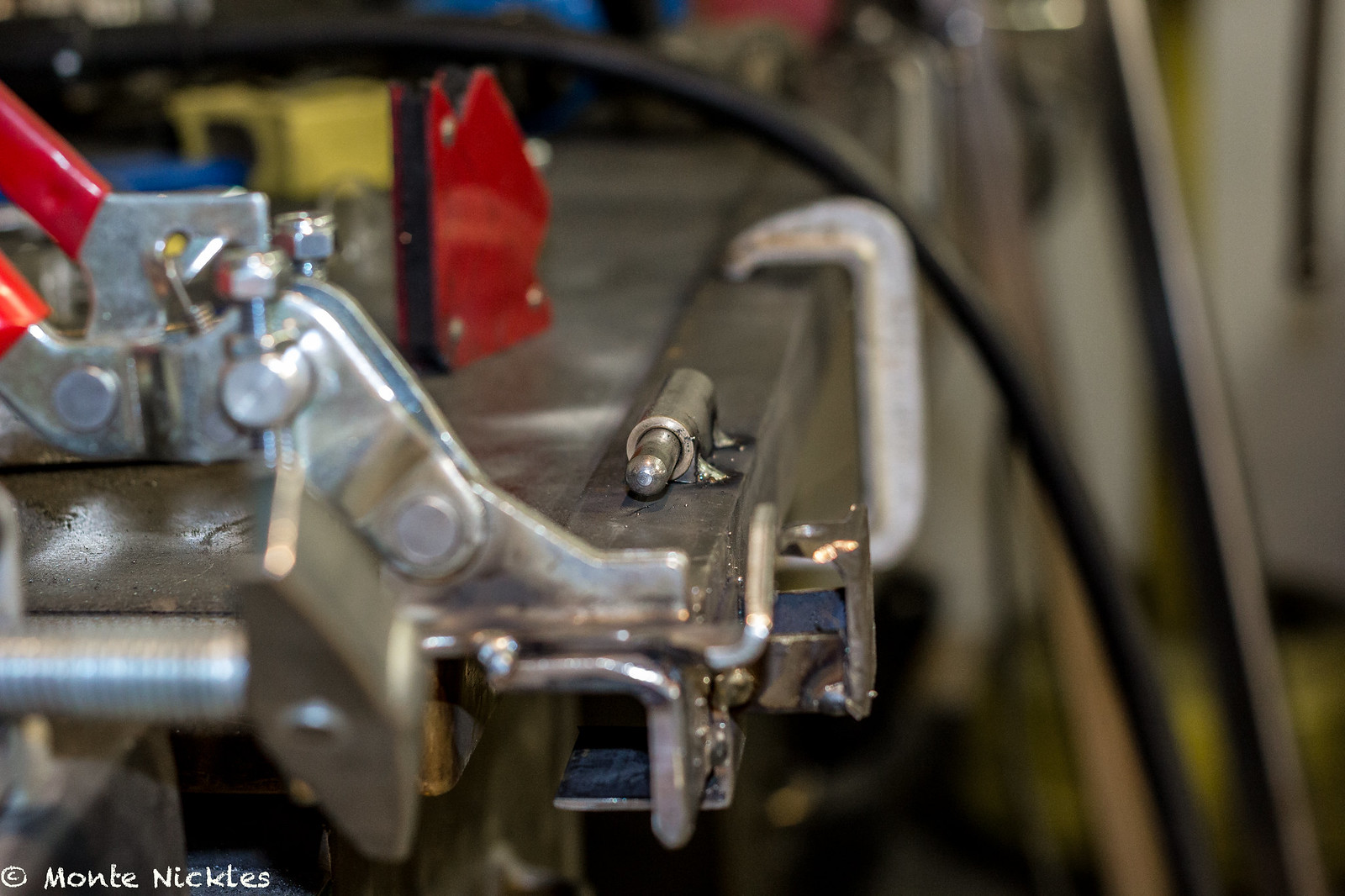

Then I cut holes for the lights and the recovery points. The recovery points tie straight into the .25'' frame mount plates. Mounting the spindle was tricky. I used a square and my eye to get it as close as possible. But really you have to wait till putting on the swing bar to really see how it lines up.

Roughed in..

IMG_8923

IMG_8923 by

digirat99, on Flickr

Of course many people stopped by to BS

it was a fun time

IMG_8925

IMG_8925 by

digirat99, on Flickr

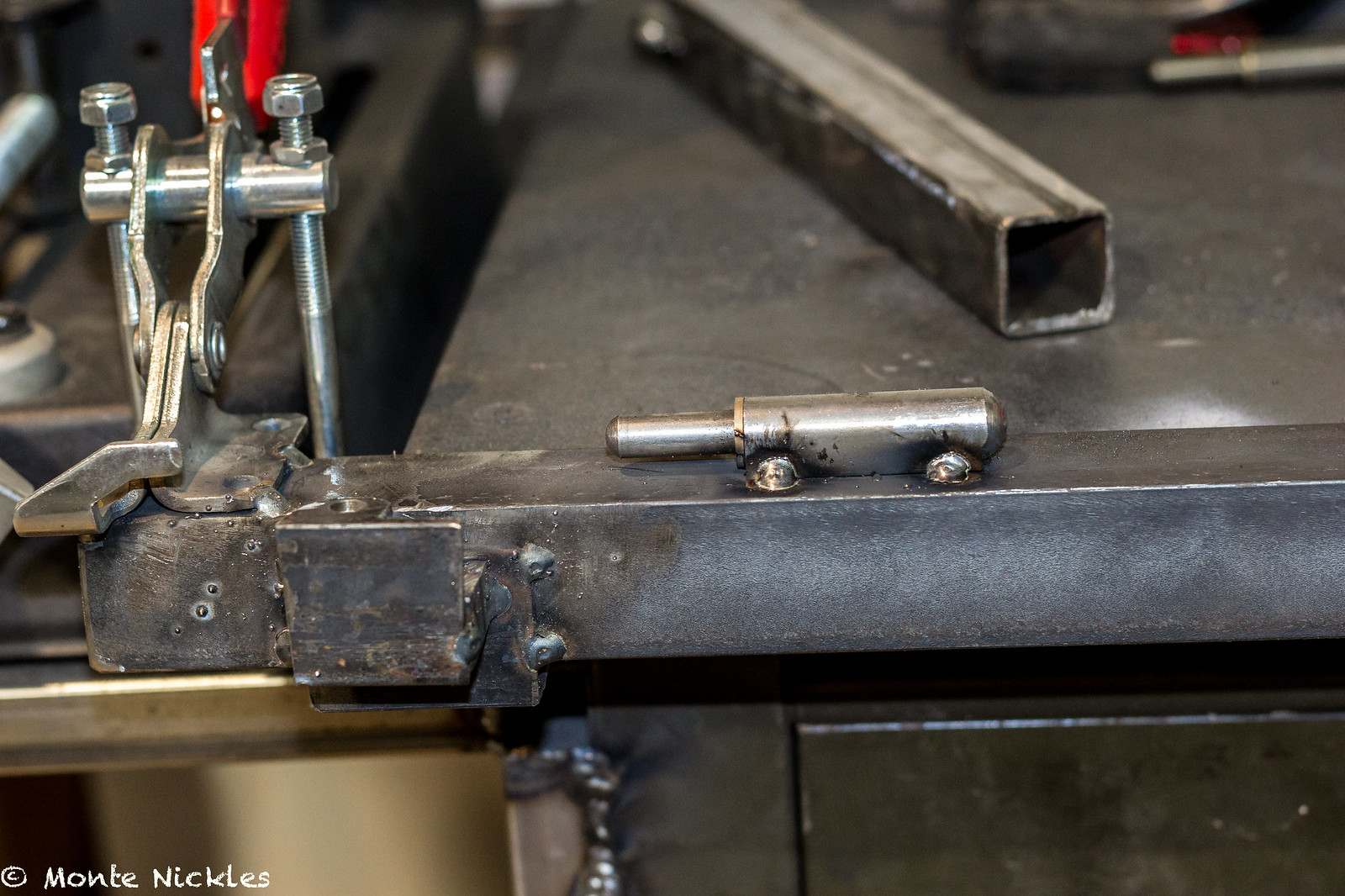

Then got back to work. I used .25'' wall square tubing to match the 2'' receiver and triangulated it back in a way that half of it was on the face of the 3/16'' plate on the bumper and the other was on the .25'' mount brackets. I also added another section of 3/16'' to the bumper side to make sure any pulling done with this thing would hold.

IMG_8927

IMG_8927 by

digirat99, on Flickr

IMG_8937

IMG_8937 by

digirat99, on Flickr

Lovely tac welds..

IMG_8938

IMG_8938 by

digirat99, on Flickr

Burned it in

IMG_8936

IMG_8936 by

digirat99, on Flickr

IMG_8931

IMG_8931 by

digirat99, on Flickr

Then Jon got there. Head of HurrDurr Fab. Where I told him of my vison and what I wanted and how I had roughly planned on how to implement it. He wasted no time and jumped in to help

IMG_8940

IMG_8940 by

digirat99, on Flickr

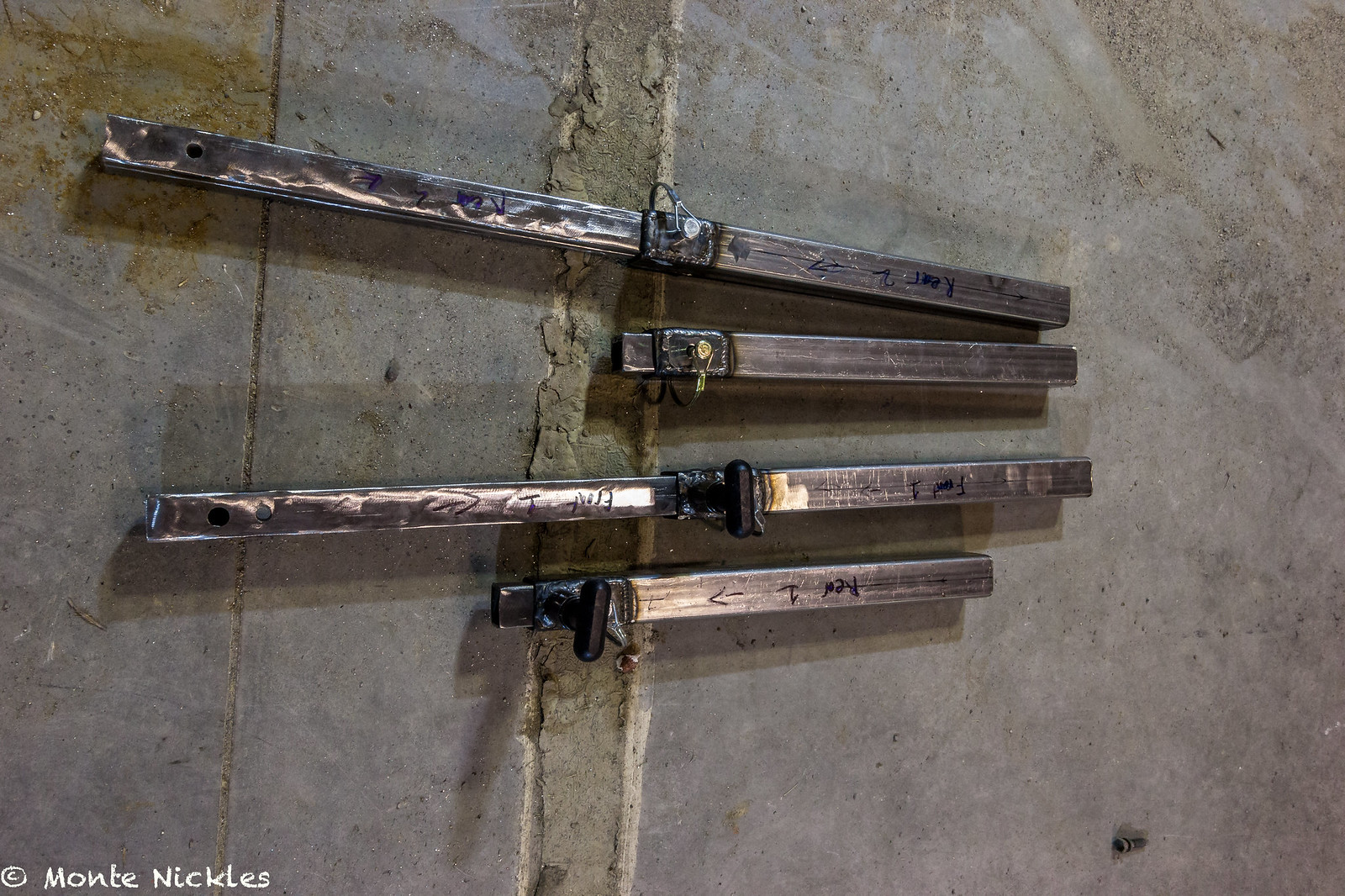

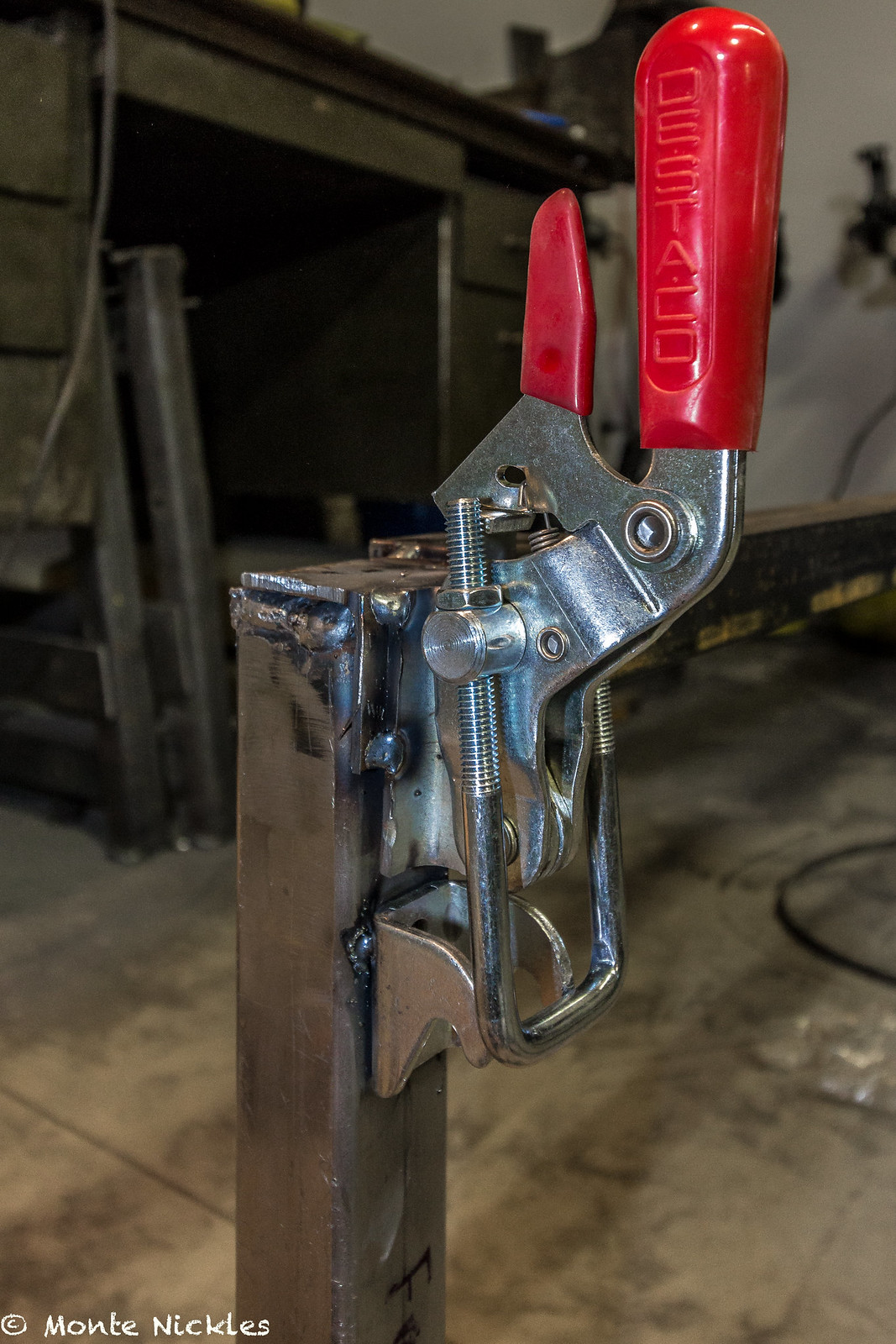

I gave Jon the job of cutting the pieces for the side protection and the corners. My Dad stopped briefly to help with me with the swingout tube

IMG_8954

IMG_8954 by

digirat99, on Flickr

IMG_8956

IMG_8956 by

digirat99, on Flickr

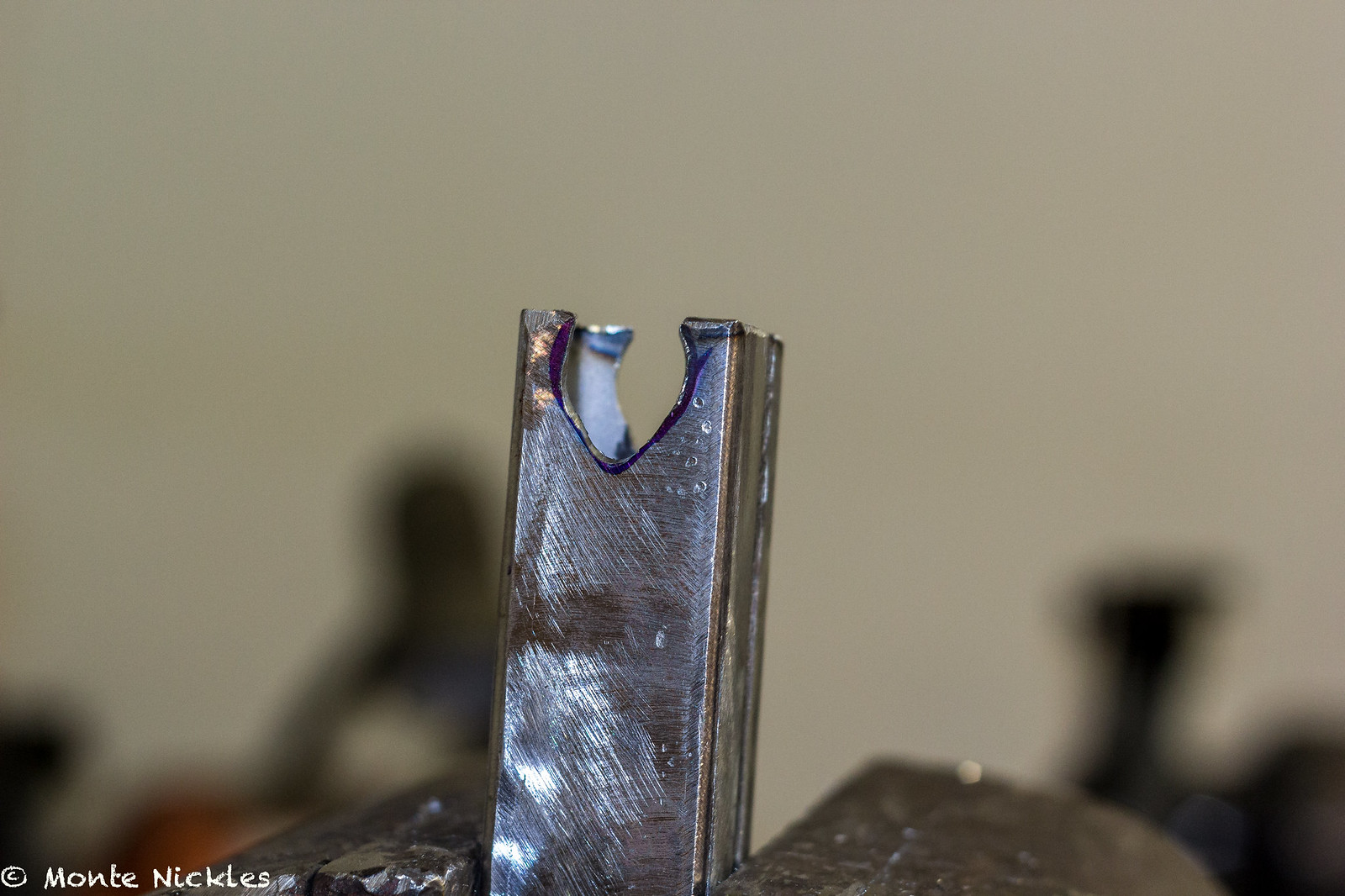

I had bought just the right amount of tube and there was a perfect full size section to do what I had wanted to originally for the side protection. I did just like I did with main section and had Jon cut in into two Ls.

IMG_8957

IMG_8957 by

digirat99, on Flickr

As you can see. It not only allows for plate for the under side protection but has the nice top beveled edge. Which makes it stronger and looks a hell of a lot better then straight plate.

IMG_8960

IMG_8960 by

digirat99, on Flickr

IMG_8961

IMG_8961 by

digirat99, on Flickr

LongTravel Install-145.jpg by Monte Nickles Photos, on Flickr

LongTravel Install-145.jpg by Monte Nickles Photos, on Flickr LongTravel Install-146.jpg by Monte Nickles Photos, on Flickr

LongTravel Install-146.jpg by Monte Nickles Photos, on Flickr LongTravel Install-147.jpg by Monte Nickles Photos, on Flickr

LongTravel Install-147.jpg by Monte Nickles Photos, on Flickr LongTravel Install-148.jpg by Monte Nickles Photos, on Flickr

LongTravel Install-148.jpg by Monte Nickles Photos, on Flickr LongTravel Install-149.jpg by Monte Nickles Photos, on Flickr

LongTravel Install-149.jpg by Monte Nickles Photos, on Flickr

SOS extras-9.jpg

SOS extras-9.jpg IMG_3208.jpg

IMG_3208.jpg IMG_8904

IMG_8904 IMG_8907

IMG_8907 IMG_8915

IMG_8915 IMG_8920

IMG_8920 IMG_8922

IMG_8922 IMG_8923

IMG_8923 IMG_8925

IMG_8925 IMG_8927

IMG_8927 IMG_8937

IMG_8937 IMG_8938

IMG_8938 IMG_8936

IMG_8936 IMG_8931

IMG_8931 IMG_8940

IMG_8940 IMG_8954

IMG_8954 IMG_8956

IMG_8956 IMG_8957

IMG_8957 IMG_8960

IMG_8960 IMG_8961

IMG_8961 IMG_8964

IMG_8964 IMG_8966

IMG_8966 IMG_8968

IMG_8968 IMG_8972

IMG_8972 IMG_8974

IMG_8974 IMG_8976

IMG_8976 IMG_8979

IMG_8979 IMG_8980

IMG_8980 IMG_8982

IMG_8982 IMG_8984

IMG_8984 IMG_8996

IMG_8996 IMG_8995

IMG_8995

IMG_8999

IMG_8999 IMG_9004

IMG_9004 IMG_9005

IMG_9005 IMG_9011

IMG_9011 IMG_9012

IMG_9012 IMG_9015

IMG_9015 IMG_9016

IMG_9016 IMG_9017

IMG_9017 IMG_9026

IMG_9026 IMG_9024

IMG_9024 IMG_9215

IMG_9215 IMG_9028

IMG_9028 IMG_9223

IMG_9223 IMG_9217

IMG_9217 IMG_9040

IMG_9040 IMG_9041

IMG_9041 IMG_9043

IMG_9043 IMG_9049

IMG_9049 IMG_9054

IMG_9054 IMG_9059

IMG_9059 IMG_9060

IMG_9060 IMG_9063

IMG_9063 IMG_9065

IMG_9065 IMG_9067

IMG_9067 IMG_9150

IMG_9150 IMG_9136

IMG_9136 IMG_9137

IMG_9137 IMG_9140

IMG_9140 IMG_9141

IMG_9141 IMG_9142

IMG_9142 IMG_9145

IMG_9145 IMG_9146

IMG_9146 IMG_9148

IMG_9148 IMG_9209

IMG_9209 IMG_9210

IMG_9210 IMG_9199

IMG_9199 IMG_9151

IMG_9151 IMG_9152

IMG_9152 IMG_9106

IMG_9106 IMG_9091

IMG_9091 IMG_9095

IMG_9095 IMG_9110

IMG_9110 BedRackRedo.jpg

BedRackRedo.jpg BedRackRedo-2.jpg

BedRackRedo-2.jpg BedRackRedo-3.jpg

BedRackRedo-3.jpg BedRackRedo-4.jpg

BedRackRedo-4.jpg BedRackRedo-5.jpg

BedRackRedo-5.jpg BedRackRedo-6.jpg

BedRackRedo-6.jpg BedRackRedo-7.jpg

BedRackRedo-7.jpg BedRackRedo-8.jpg

BedRackRedo-8.jpg BedRackRedo-9.jpg

BedRackRedo-9.jpg BedRackRedo-10.jpg

BedRackRedo-10.jpg BedRackRedo-11.jpg

BedRackRedo-11.jpg BedRackRedo-12.jpg

BedRackRedo-12.jpg BedRackRedo-13.jpg

BedRackRedo-13.jpg BedRackRedo-14.jpg

BedRackRedo-14.jpg BedRackRedo-15.jpg

BedRackRedo-15.jpg BedRackRedo-16.jpg

BedRackRedo-16.jpg BedRackRedo-17.jpg

BedRackRedo-17.jpg BedRackRedo-18.jpg

BedRackRedo-18.jpg BedRackRedo-19.jpg

BedRackRedo-19.jpg BedRackRedo-21.jpg

BedRackRedo-21.jpg BedRackRedo-20.jpg

BedRackRedo-20.jpg BedRackRedo-22.jpg

BedRackRedo-22.jpg BedRackRedo-23.jpg

BedRackRedo-23.jpg BedRackRedo-24.jpg

BedRackRedo-24.jpg BedRackRedo-25.jpg

BedRackRedo-25.jpg BedRackRedo-26.jpg

BedRackRedo-26.jpg New Bed Rack.jpg

New Bed Rack.jpg New Bed Rack-2.jpg

New Bed Rack-2.jpg New Bed Rack-3.jpg

New Bed Rack-3.jpg New Bed Rack-6.jpg

New Bed Rack-6.jpg New Bed Rack-7.jpg

New Bed Rack-7.jpg New Bed Rack-9.jpg

New Bed Rack-9.jpg New Bed Rack-10.jpg

New Bed Rack-10.jpg New Bed Rack-11.jpg

New Bed Rack-11.jpg New Bed Rack-12.jpg

New Bed Rack-12.jpg New Bed Rack-13.jpg

New Bed Rack-13.jpg New Bed Rack-16.jpg

New Bed Rack-16.jpg New Bed Rack-17.jpg

New Bed Rack-17.jpg New Bed Rack-14.jpg

New Bed Rack-14.jpg New Bed Rack-18.jpg

New Bed Rack-18.jpg New Bed Rack-19.jpg

New Bed Rack-19.jpg New Bed Rack-20.jpg

New Bed Rack-20.jpg New Bed Rack-21.jpg

New Bed Rack-21.jpg New Bed Rack-22.jpg

New Bed Rack-22.jpg New Bed Rack-23.jpg

New Bed Rack-23.jpg New Bed Rack-25.jpg

New Bed Rack-25.jpg New Bed Rack-27.jpg

New Bed Rack-27.jpg New Bed Rack-24.jpg

New Bed Rack-24.jpg New Bed Rack-26.jpg

New Bed Rack-26.jpg New Bed Rack-28.jpg

New Bed Rack-28.jpg New Bed Rack-29.jpg

New Bed Rack-29.jpg New Bed Rack-30.jpg

New Bed Rack-30.jpg New Bed Rack-31.jpg

New Bed Rack-31.jpg New Bed Rack-32.jpg

New Bed Rack-32.jpg New Bed Rack-42.jpg

New Bed Rack-42.jpg New Bed Rack-41.jpg

New Bed Rack-41.jpg New Bed Rack-43.jpg

New Bed Rack-43.jpg New Bed Rack-44.jpg

New Bed Rack-44.jpg New Bed Rack-45.jpg

New Bed Rack-45.jpg New Bed Rack-46.jpg

New Bed Rack-46.jpg New Bed Rack-49.jpg

New Bed Rack-49.jpg New Bed Rack-50.jpg

New Bed Rack-50.jpg New Bed Rack-47.jpg

New Bed Rack-47.jpg New Bed Rack-48.jpg

New Bed Rack-48.jpg New Bed Rack-51.jpg

New Bed Rack-51.jpg New Bed Rack-52.jpg

New Bed Rack-52.jpg New Bed Rack-53.jpg

New Bed Rack-53.jpg New Bed Rack-54.jpg

New Bed Rack-54.jpg New Bed Rack-55.jpg

New Bed Rack-55.jpg New Bed Rack-56.jpg

New Bed Rack-56.jpg New Bed Rack-57.jpg

New Bed Rack-57.jpg New Bed Rack-58.jpg

New Bed Rack-58.jpg New Bed Rack-59.jpg

New Bed Rack-59.jpg New Bed Rack-60.jpg

New Bed Rack-60.jpg New Bed Rack-61.jpg

New Bed Rack-61.jpg New Bed Rack-62.jpg

New Bed Rack-62.jpg New Bed Rack-63.jpg

New Bed Rack-63.jpg Bed Rack

Bed Rack Bed Rack 2

Bed Rack 2 Bed Rack 3

Bed Rack 3 New Bed Rack-2.jpg

New Bed Rack-2.jpg New Bed Rack.jpg

New Bed Rack.jpg New Bed Rack-72.jpg

New Bed Rack-72.jpg New Bed Rack-73.jpg

New Bed Rack-73.jpg New Bed Rack-75.jpg

New Bed Rack-75.jpg New Bed Rack-74.jpg

New Bed Rack-74.jpg New Bed Rack-76.jpg

New Bed Rack-76.jpg New Bed Rack-33.jpg

New Bed Rack-33.jpg New Bed Rack-34.jpg

New Bed Rack-34.jpg New Bed Rack-37.jpg

New Bed Rack-37.jpg New Bed Rack-38.jpg

New Bed Rack-38.jpg New Bed Rack-40.jpg

New Bed Rack-40.jpg New Bed Rack-39.jpg

New Bed Rack-39.jpg New Bed Rack-35.jpg

New Bed Rack-35.jpg New Bed Rack-36.jpg

New Bed Rack-36.jpg New Bed Rack-64.jpg

New Bed Rack-64.jpg New Bed Rack-65.jpg

New Bed Rack-65.jpg New Bed Rack-66.jpg

New Bed Rack-66.jpg New Bed Rack-67.jpg

New Bed Rack-67.jpg New Bed Rack-68.jpg

New Bed Rack-68.jpg New Bed Rack-69.jpg

New Bed Rack-69.jpg New Bed Rack-70.jpg

New Bed Rack-70.jpg New Bed Rack-90.jpg

New Bed Rack-90.jpg New Bed Rack-88.jpg

New Bed Rack-88.jpg New Bed Rack-89.jpg

New Bed Rack-89.jpg New Bed Rack-78.jpg

New Bed Rack-78.jpg New Bed Rack-79.jpg

New Bed Rack-79.jpg New Bed Rack-80.jpg

New Bed Rack-80.jpg New Bed Rack-81.jpg

New Bed Rack-81.jpg New Bed Rack-82.jpg

New Bed Rack-82.jpg New Bed Rack-83.jpg

New Bed Rack-83.jpg New Bed Rack-85.jpg

New Bed Rack-85.jpg New Bed Rack-86.jpg

New Bed Rack-86.jpg New Bed Rack-77.jpg

New Bed Rack-77.jpg Swingout Redo.jpg

Swingout Redo.jpg Swingout Redo-2.jpg

Swingout Redo-2.jpg Swingout Redo-3.jpg

Swingout Redo-3.jpg Swingout Redo-4.jpg

Swingout Redo-4.jpg Swingout Redo-5.jpg

Swingout Redo-5.jpg Swingout Redo-6.jpg

Swingout Redo-6.jpg Swingout Redo-7.jpg

Swingout Redo-7.jpg Swingout Redo-8.jpg

Swingout Redo-8.jpg Swingout Redo-9.jpg

Swingout Redo-9.jpg Swingout Redo-10.jpg

Swingout Redo-10.jpg Swingout Redo-11.jpg

Swingout Redo-11.jpg Swingout Redo-12.jpg

Swingout Redo-12.jpg Swingout Redo-13.jpg

Swingout Redo-13.jpg Swingout Redo-14.jpg

Swingout Redo-14.jpg Swingout Redo-15.jpg

Swingout Redo-15.jpg Swingout Redo-16.jpg

Swingout Redo-16.jpg Swingout Redo-17.jpg

Swingout Redo-17.jpg Swingout Redo-18.jpg

Swingout Redo-18.jpg Swingout Redo-19.jpg

Swingout Redo-19.jpg Swingout Redo-20.jpg

Swingout Redo-20.jpg Swingout Redo-21.jpg

Swingout Redo-21.jpg Swingout Redo-22.jpg

Swingout Redo-22.jpg Family 4th Camping.jpg

Family 4th Camping.jpg Family 4th Camping-2.jpg

Family 4th Camping-2.jpg Family 4th Camping-3.jpg

Family 4th Camping-3.jpg Family 4th Camping-4.jpg

Family 4th Camping-4.jpg Family 4th Camping-5.jpg

Family 4th Camping-5.jpg Family 4th Camping-6.jpg

Family 4th Camping-6.jpg Family 4th Camping-7.jpg

Family 4th Camping-7.jpg Family 4th Camping-8.jpg

Family 4th Camping-8.jpg Family 4th Camping-9.jpg

Family 4th Camping-9.jpg Family 4th Camping-10.jpg

Family 4th Camping-10.jpg Family 4th Camping-11.jpg

Family 4th Camping-11.jpg Family 4th Camping-12.jpg

Family 4th Camping-12.jpg Family 4th Camping-13.jpg

Family 4th Camping-13.jpg Family 4th Camping-14.jpg

Family 4th Camping-14.jpg Family 4th Camping-15.jpg

Family 4th Camping-15.jpg Family 4th Camping-16.jpg

Family 4th Camping-16.jpg Family 4th Camping-17.jpg

Family 4th Camping-17.jpg Family 4th Camping-18.jpg

Family 4th Camping-18.jpg Family 4th Camping-19.jpg

Family 4th Camping-19.jpg Family 4th Camping-20.jpg

Family 4th Camping-20.jpg Family 4th Camping-21.jpg

Family 4th Camping-21.jpg Family 4th Camping-22.jpg

Family 4th Camping-22.jpg Family 4th Camping-23.jpg

Family 4th Camping-23.jpg Family 4th Camping-24.jpg

Family 4th Camping-24.jpg Family 4th Camping-25.jpg

Family 4th Camping-25.jpg Family 4th Camping-26.jpg

Family 4th Camping-26.jpg Family 4th Camping-27.jpg

Family 4th Camping-27.jpg Family 4th Camping-28.jpg

Family 4th Camping-28.jpg Family 4th Camping-29.jpg

Family 4th Camping-29.jpg Family 4th Camping-30.jpg

Family 4th Camping-30.jpg Family 4th Camping-31.jpg

Family 4th Camping-31.jpg Family 4th Camping-32.jpg

Family 4th Camping-32.jpg Family 4th Camping-33.jpg

Family 4th Camping-33.jpg Family 4th Camping-34.jpg

Family 4th Camping-34.jpg Family 4th Camping-35.jpg

Family 4th Camping-35.jpg Family 4th Camping-36.jpg

Family 4th Camping-36.jpg Family 4th Camping-37.jpg

Family 4th Camping-37.jpg Family 4th Camping-38.jpg

Family 4th Camping-38.jpg Family 4th Camping-39.jpg

Family 4th Camping-39.jpg Family 4th Camping-40.jpg

Family 4th Camping-40.jpg Family 4th Camping-41.jpg

Family 4th Camping-41.jpg Family 4th Camping-42.jpg

Family 4th Camping-42.jpg Family 4th Camping-43.jpg

Family 4th Camping-43.jpg Family 4th Camping-44.jpg

Family 4th Camping-44.jpg