Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Utilitarian-Camper 2nd Gen Tacoma

- Thread starter lx450landcruiser

- Start date

lx450landcruiser

Explorer

I have been scratching my brain for awhile now on what route to take with the tent. For me (and my wife) A place to stand up and change seems like a valuable trait for the camper design. However I also value the total height of the camper when closed and in transit. The last camper came out quite a bit taller then even I had planned and I was left a bit disappointed from the start (hence the new version) I have looked through almost all of the roof top tents in terms of dimensions and they all seem to share a frustrating similarity which is their travel height. if your talking about folding style tents the majority seem to be around 11-12" height. The Frontrunner claims theirs is around 8" with out the ladder. The auto home hard shell tents all have a total height around 12-13 inches as well. The issue I run into is by keeping the rear of the camper vertical versus slanted like the previous version I do not have enough length for a full foot print tent. This means I either extend the camper like the previous version or have the camper extended above the roof of the truck toward the front. I owned a Eezi awn in the past and absolutely loved that tent and used it on several different vehicles. It was extremely well made and gave me no issues other then the occasional frustration with the cover. Currently Im playing with the idea of modifying an eezi awn 1600 tent to fold off the passenger side of the truck with access from inside the camper and or the latter from the outside. I would end up modifying most of the tent (removing one floor, possibly the hinges, supports ect.) in an effort to reduce the over all height as much as possible. This would also remove the frustration of a soft cover by having the hard roof of the camper be its cover. Im still going through measurements at the moment and if anyone has an Eezi awn 1600 and would be willing to take some measurements for me I would appreciate it very much.

lx450landcruiser

Explorer

Fabricating a tent from scratch is on the bucket list for sure but with very little sewing skills under my belt I don't see it happening to the quality I would want. I spent many many hours talking with tent designers, upholsters, boat top makers etc... and non of them were willing to mess with the previous tent. If i are doing a clam shell style tent (which was the original idea) I would be all over it as it seems simple enough to bang out myself. with a tent that requires multiple folds, windows, rain fly, etc... its better left to those who have been doing it for awhile. I still don't understand why some of these tents are as "tall" as they are they certainly don't need to be.

lx450landcruiser

Explorer

Question, why not put a drawer system in the area in the middle under the deck? Using the plain flatbed you are loosing the space where the base of the bed, between the stock wheel wells would be. Sorry, there is probably an easier way to describe that spot.

I do plan to use that space. The stock Tacoma has the spare tire carrier riveted and bolted in that area (it protrudes up) when I did my current bed I cut it out and re attached it to the bottom of the flatbed allowing for my larger spare to still fit in the stock location. The new flat will incorporate as you said a drawer or potentially a "ramp/stairs" This bed only sits about 5 inches off the frame rails however. Since this camper will not have the over hang in the rear that will allow me to do a swing away for my spare should I choose that route.

lx450landcruiser

Explorer

Well after more debating I have decided to investigate the original idea of the "clam shell" pop up. Since this camper is shorter the sleeping platform isn't long enough to support this, nor was there enough space to stand up in the back to change if I hinged directly from the front. I have since designed a scissor hinge to take care of that issue. As for the length I am thinking of a short flip out the rear. This should allow for a decent length, a simplified tent design, and a mostly hard roof. An advantage to this hinge design is I can incorporate the sidewall flanges into the hinge, reducing the over all height and number of parts.

Few shots of the hinge closed and open as well as a rough idea of tent size

Few shots of the hinge closed and open as well as a rough idea of tent size

Attachments

Last edited:

washington taco

Explorer

I talked with the guy that bought Mikes old camper, they are LOVING IT! Looks real good on a regular cab as well!

lx450landcruiser

Explorer

Spotted at the Northwest Overland Rally. Looks like its getting used!

I dig the side bars and rear carrier.

lx450landcruiser

Explorer

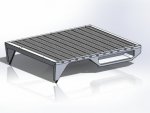

V3 Flatbed

V3 Flatbed.

Well I am finishing up the design of the V3 flatbed. Don't mind the "flaps" in the cad drawings those will be bent over and welded to cap the ends for strength. I'm pretty happy with the layout and its as low profile as I could make it. The lower the profile the more height I can squeeze out of the interior of the camper to avoid getting too high above the roof line of the truck. I incorporated "slots" in sides of the bed which allow for tie down hooks to slide in and stay put when strapping things down by yourself. The deck is made up of extruded aluminum planking which gives me "gussets" roughly every 3 inches for strength and for welding/mounting. The rear drawers will end up being about 13" deep by 30.5" wide by 6" tall. One aspect I'm pretty excited about are the mounting channels. They will be laser cut and bent from .19" thick aluminum and have the exact mounting holes per Toyotas factory blue prints. The frames on these Tacomas actually get gradually narrower towards the end which means the mounting holes are not in a line. They are also not flat so the rear most frame mount will also need to be 1.42" taller. I plan to turn some solid stock aluminum on the lathe and then weld these to the channel mount to solve that issue. For added strength I may end up sandwiching the mounting channel with a drilled flat bar steel but will see how strong it is when we get there. This mount should solve any issues when it comes to aligning everything for the final mounting. This also allows the flatbed to sit as close to the frame as possible with out interfering with any of the cross bars, mounting brackets, bolts, etc.. that are on the top side of the frame. Right now I'm on the fence on having someone do the welding for me or buying a Tig and giving it a go myself. I have very little Tig experience but its on my "list" so it may end up being better to start now then later.

V3 Flatbed.

Well I am finishing up the design of the V3 flatbed. Don't mind the "flaps" in the cad drawings those will be bent over and welded to cap the ends for strength. I'm pretty happy with the layout and its as low profile as I could make it. The lower the profile the more height I can squeeze out of the interior of the camper to avoid getting too high above the roof line of the truck. I incorporated "slots" in sides of the bed which allow for tie down hooks to slide in and stay put when strapping things down by yourself. The deck is made up of extruded aluminum planking which gives me "gussets" roughly every 3 inches for strength and for welding/mounting. The rear drawers will end up being about 13" deep by 30.5" wide by 6" tall. One aspect I'm pretty excited about are the mounting channels. They will be laser cut and bent from .19" thick aluminum and have the exact mounting holes per Toyotas factory blue prints. The frames on these Tacomas actually get gradually narrower towards the end which means the mounting holes are not in a line. They are also not flat so the rear most frame mount will also need to be 1.42" taller. I plan to turn some solid stock aluminum on the lathe and then weld these to the channel mount to solve that issue. For added strength I may end up sandwiching the mounting channel with a drilled flat bar steel but will see how strong it is when we get there. This mount should solve any issues when it comes to aligning everything for the final mounting. This also allows the flatbed to sit as close to the frame as possible with out interfering with any of the cross bars, mounting brackets, bolts, etc.. that are on the top side of the frame. Right now I'm on the fence on having someone do the welding for me or buying a Tig and giving it a go myself. I have very little Tig experience but its on my "list" so it may end up being better to start now then later.

Attachments

Last edited:

Similar threads

- Replies

- 2

- Views

- 500

- Replies

- 7

- Views

- 3K

- Replies

- 25

- Views

- 8K

- Replies

- 12

- Views

- 4K