I guess a little more detail on each of the designs may be in order.

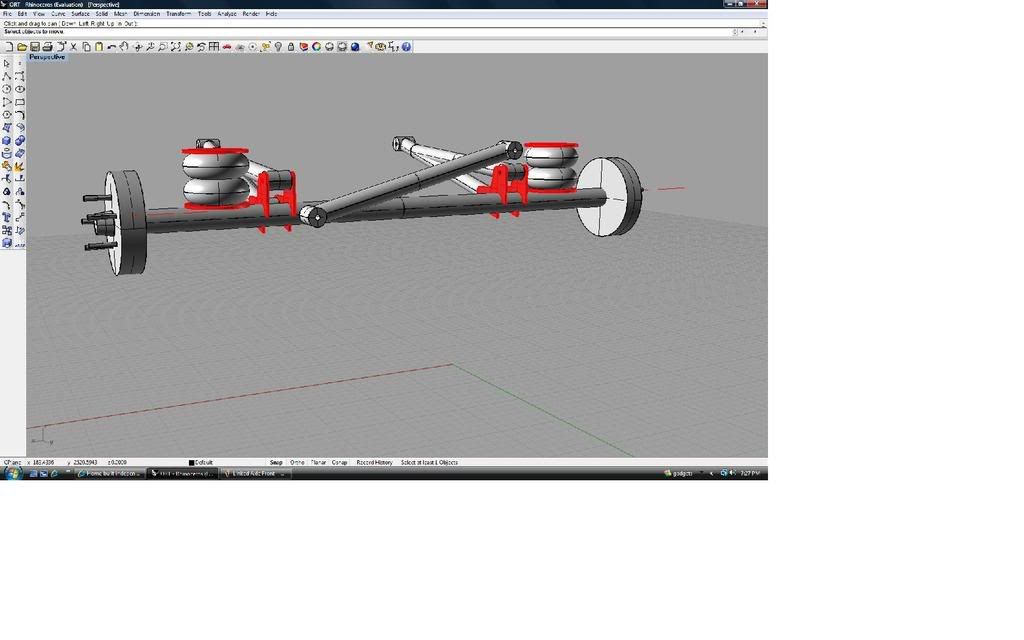

Three Link

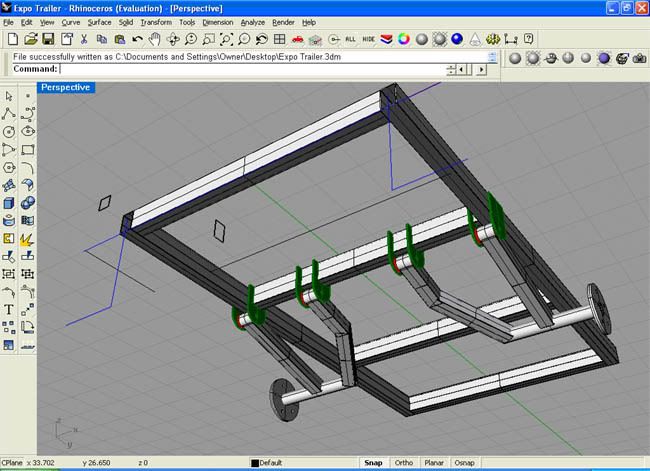

The three link set up is designed so that it would be easily reproducible by others and still retain the benefits of having an airbag suspension. The brackets for the links could be designed on a CAD program so that it would be a simple matter of sending the file to a local fabrication shop with either CNC plasma or laser. This would provide some great brackets to weld on to the axle tube for locating the trailing arms.

For the three link design I'm inclined to stay with the panhard bar instead of a Watts link. Advantages include less moving parts, less to fail, and simpler to fabricate. The panhard bar would be mounted parallel to the axle to minimize the side to side shift as the suspension cycles. It would also have adjustable rod ends, one RH thread and one LH, so that you could just loosen the jam nuts and turn the center part of the link to center the axle under the trailer. Lock the jam nuts and the setting is, well set.

The trailing arms would use poly bushings at the axle end and rod ends at the frame end. The poly bushings would be fixed and the rod ends would be threaded to adjust the location of the axle front to back and make up for any inconsistencies in manufacturing the trailing arm.

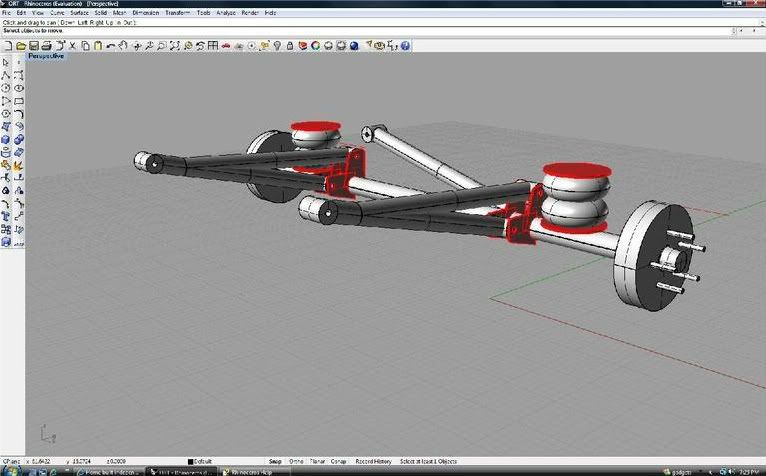

Independant

The independent suspension would be more involved and more difficult to reproduce. The overall parts count for bushings and joints would be less than the three link. Angles, alignment, and adjustability do become a lot more critical though. In order to mitigate these items I would do the following:

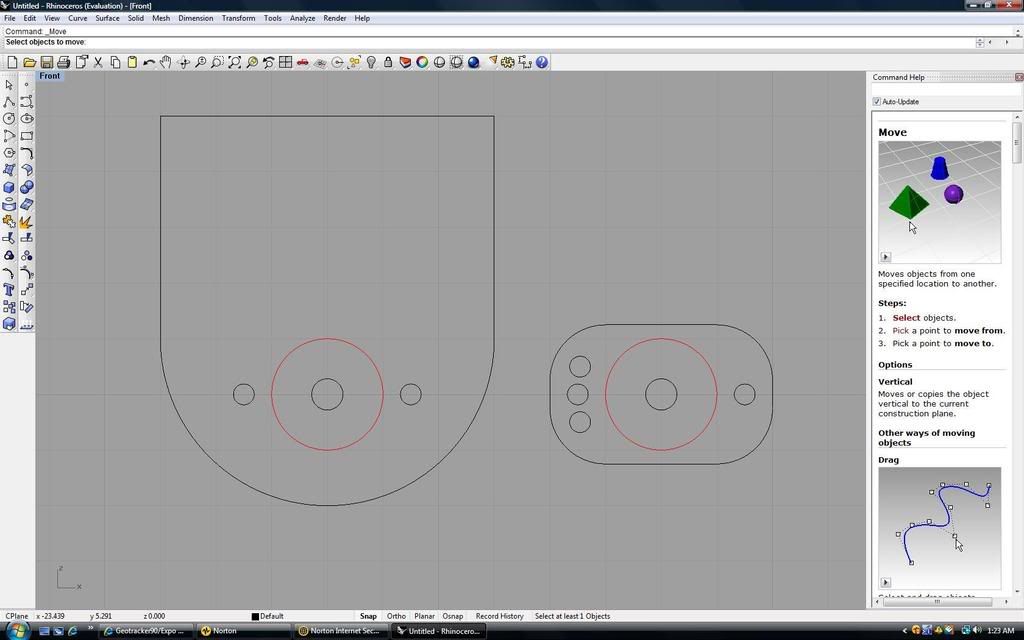

Camber plates - in the second picture that I posted I have designed a form of camber adjustment.

Just for the sake of full disclosure I must say that these are of my own design and are not proven at this point. I have an associates degree in Automotive Technology (aka - mechanic) and have performed hundreds of passenger car and truck alignments. I also currently work in an engineering firm with Mechanical Engineers on a daily basis, although I am not a Mechanical Engineer. All this means is that I feel like I understand fairly well the angles and how they interact with the design of the suspension.

The camber plates are a way of moving the outboard joint of the trailing arm either above or below the centerline of the inboard joint. This in effect either tilts the top of the tire in or out changing the camber of the suspension. The center hole of the larger plate will actually be slotted to allow for this adjustment. The smaller plate will bolt on to the larger plate to provide the correct positioning for the outboard trailing arm joint.

The inboard joint will have a threaded rod end style joint. This will allow for the adjustment of toe-in / toe-out in the suspension. If you extend the rod end further out from the trailing arm this will move the front of the tire closer to the centerline of the trailer and increase toe-in. Reduce the rod end extension (screw it in some) and you are in effect moving the front of the tire away from the centerline of the trailer and inducing more of a toe-out posture.

To make these adjustments work with out binding the suspension I will probably have to go to a rod end arrangement at all the attachment points between the trailing arms and the frame.

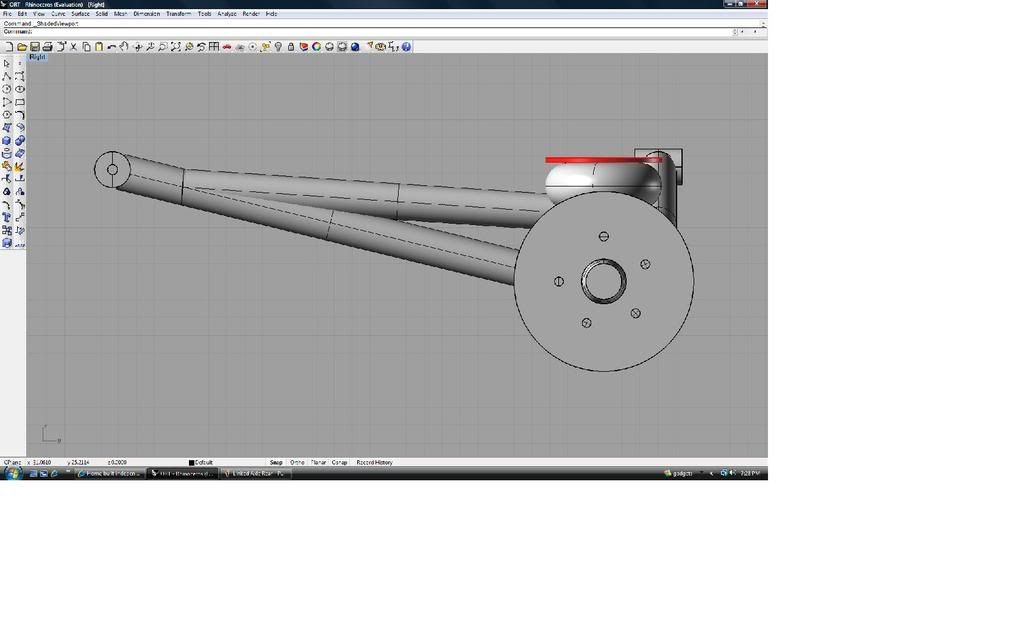

I had thought about fabricating the trailing arms from components, but the more I think about it the more I believe that it would be better to order a 3,500 lb axle tube and using a jig weld up the trailing arm pieces. The two trailing arms could then be cut loose from each other.

Other Thoughts

As far as shocks go I'm interested in exploring a bell-crank and linkage assembly that would lay the shock down parallel to the trailer frame. I see that some of the Jeep and full-sized truck lift kit companies have sucessfully used this arrangement in their designs. The trick to doing this will be getting the ratio of the lever or bell-crank correct as well as packaging it all in the limited space.

Well I've ramble don way too long, so i had better quit before I think of anything else.

Mike