All but the chainsaw, tire chains, drills, FSM, and spare parts are kept in the truck at all times.

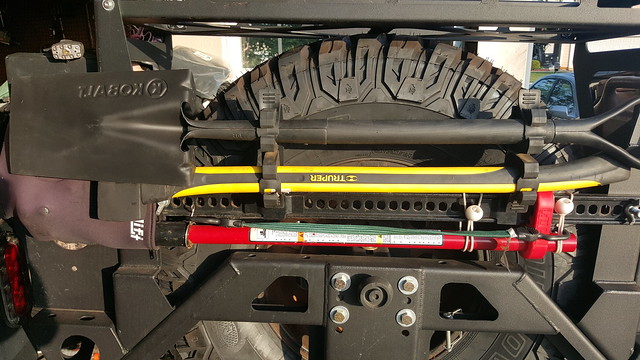

From the Top Left

- Axe

. *I would recommend a single bit axe, so you can drive it out with a hammer if you get it stuck.

- Hatchet

- 48" Cast Hi-Lift

- Ice Scraper, Squeegie, Snow Brush

. *This is very useful for the squeegie so you can get mud off the windshield without using all of you washer fluid.

- Spade

- 18v Milwaukee Impact Driver

- 18v Milwaukee Drill

- 18v Milwaukee Spare Battery

- 50+ piece Impact Driver Bit Set

- 50+ piece Milwaukee Drill Bit Set

. *These actually ended up being extremely helpful.

. *Was able to repair a severe failure on the suspension on the Ford on our most recent trip. When I get that trip report done, I'll put a link to it.

- 149 piece Crescent Tool Kit

. *I like this kit so much, I bought two and keep one in my car as well. Very recommend.

- 20' #2 jumper cables

- (2) 3/8" Snatch Blocks

. *These are usually used for logging and have grease-able fittings.

- (6) 3/4" Shackles

- (1) 1/2" Shackle

. *This is only used when pulling little cars out of the snow when their recovery point is too small for my 3/4" shackles.

- 4 ton Hydraulic Bottle Jack

- Hitch Mount 3/4" Shackle w/ 5/8" Class IV locking SS pin

- 4-way Lug Wrench

- (4) 10 mm Diamond Pattern Tire Chains

. *Highly recommend these diamond pattern (European Hoop Style) chains as opposed to the ladder type chains. They stay a lot tighter on the tire than the ladder type do; and therefore don't destroy your fender-wells. They do come in different sizes (thickness). So make sure you get the thicker ones. Also recommend doubling up on the rubber-tensioners. Also, if you get the tensioners with hooks on them, make sure that you put them on with the hooks pointing out... learned that one the hard way.

- (3) 6' 6400 lb lifting straps (Harbor Freight)

- (3) 30' 27,000 lb Poly Recovery Straps (Harbor Freight)

- Husky 12v Inflator

. *This will go away when I get on-board air

- Hitch Tray Mounted Smittybilt XRC8 8000lb winch w/ Tweco Welding Plugs

- (Not Pictured) 30' 3/8" Winch Extension Cable

- (Not Pictured) Deer Skin Dedicated Winching Gloves

- Fire Extinguisher

- Road Flare Kit

- Paper Towels

- General Tool Box

. - ATF Funnel

. - Regular Funnel

. - Ball Peen Hammer

. - Multimeter

. - 16ga and 12ga Electrical Wire

. - Solder

. - 10" DeWalt Crescent Wrench

. - Channel Locks

. - High Temp RTV Sealant

. - 2-part 30-min Epoxy

. - Flexible Neck Butane Lighter

. - Duct tape

. - Electrical Tape

. - Utility Knife

. - 10" Pipe Wrench

. - 5/8" Alan Key for 1/2" socket (Lowering Spare Tire)

. - Socket for Axle Nuts

. - Wire Stripper

. - WD-40

. - Strapwrench

. - Spare Headlight, Tail-light, Clearance Light bulbs.

. - Spare Fuses

. - Maglight 2AA Penlight

. - Spare U-Joints

. - C-Clamp

- Safety Glasses

. *These are actually very nice to have when you're working under the truck and there is mud, dust, and dirt falling in your face.

- Factory Service Manual

- 100' 5/8" Braided Poly Rope

- (Not Pictured) 50' 1/4" Poly Chord

- PoulanPro 140 Chainsaw

. *Would really like a 20" Stihl. But I found this almost brand-new at a garage sale for $30.

- Serpentine Belt

- (2) Spark Plug Wires

- Spark Plug

- Radiator Hose

- 4D LED Maglite

- Multipack of Zip-Ties

- Full First-Aid kit

- Hand Warmers

. *It's probably a 1 in a 1000 chance, but I blew a radiator hose when it was -10 F and had to wait about an hour for a tow home. Would very much have liked to have these. Will never not have these in the truck again.

(Additional Not Pictured)

- 2 quarts Oil

. *I've heard a lot of critique for carrying replacement fluids on the trail. The main argument is that carrying enough oil to replace all of your oil in the event of a damaged oil pan takes up a lot of room and carrying less than that won't do you any good. However, when I first bought my truck, it ran perfectly fine for several months before I changed the oil for the first time. When I drained the oil, there was little more than 1/2 a quart in it. So it is possible for it to run without severe damage with much less than 5 quarts.

- 1 quart gear oil

- 1 quart ATF

- 1 quart Bar/Chain Oil

- 1 Gallon 2-Cycle Gas Mix

- (6) Ratchet Tie-Down Strap