You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"TrailTop" modular trailer topper building components

- Thread starter jscherb

- Start date

jscherb

Expedition Leader

Jeff I check on your progress every day. I am never disappointed at your how it is coming along and what new ideas you have hatched. Thank you for keeping all of us up to date on your project. I still have hopes these will be made available to us one day.:smiley_drive:

Henry

Henry,

Thanks for following along and for your comments along the way.

I haven't decided yet if I think the TrailTop system should be a commercial product - I want to get a little further along with the proof-of-concept build before I come to any conclusions about that. So far most of my original design requirements have been met or exceeded by the prototype parts, but there's more work I want to do yet before deciding.

jscherb

Expedition Leader

I haven't decided yet if I'm going to support the hatch in the open position with gas struts or a more simple prop rod of some sort. For now in the workshop I'm using a stick:

Since this is a proof-of-concept build, I'm thinking I should do gas struts to prove how they would work with the TrailTop parts, but I'd welcome any input you guys have on hatch supports.

Since this is a proof-of-concept build, I'm thinking I should do gas struts to prove how they would work with the TrailTop parts, but I'd welcome any input you guys have on hatch supports.

Given the light weight of the hatch, I'm sure some people will elect to just use support rods. But I'm sure others will want gas struts. Since a kit user will have to figure out where to mount the struts, how to mount the struts and the specifications for the struts, it would be very helpful to prove the application and show the user at least one way to do it. Based on your prior work, I'm sure your method will be more simple, elegant and effective than the method most could come up with on their own.

jscherb

Expedition Leader

Yesterday I went to my local U-Pull junkyard to shop for some gas struts for the hatch. My SWAG engineering suggested I would find appropriate struts on a full-size SUV with a separate tailgate and lift glass in the back. I figured a lift glass with a metal frame would probably weigh just about as much as the hatch and have about as much leverage. I grabbed a pair of struts from a '95 Chevy Tahoe and they seem just about right. Here they are clamped in place as a test:

Initial tests show that these have just about the right force.

Initial tests show that these have just about the right force.

jscherb

Expedition Leader

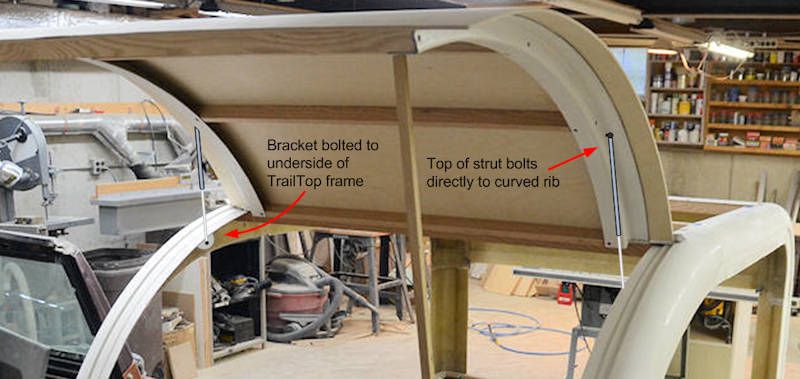

I installed the struts this morning.

The force of the struts stresses things a bit in the current stage of the build - for example, I've only got three screws on each side of the hinge, the force flexes the hinge a bit. When everything is buttoned up in the final assembly, these struts will be perfect.

The force of the struts stresses things a bit in the current stage of the build - for example, I've only got three screws on each side of the hinge, the force flexes the hinge a bit. When everything is buttoned up in the final assembly, these struts will be perfect.

jscherb

Expedition Leader

I know a lot of people wonder how to figure out the length, strength and mounting locations required for hatch struts, so maybe this will help - here's how I do it.

1. You want struts that will have a bit more force than the load they need to support. The load can be found with a bathroom scale and a stick. Pick a place where you think you'd like to attach the struts, put a bathroom scale on the floor of the trailer, and a stick between that point and the scale. The scale will tell you how much downward force the hatch is exerting at that point. The magenta line in the drawing below shows a weigh point that could be used for this hatch. Let's say the scale reads 40 lbs., two 25-lbs. force struts should do the job nicely, and 30-lb. struts would give a little more margin to protect from winds moving the hatch. (The stick in this photo isn't being used for weight measurement, it's holding up the hatch - this is just an edit of a photo I already had on hand).

2. Measure the vertical length from the attachment point you'd like to use on the hatch to the attachment point you'd like to use on the camper shell. Checking a website like McMaster-Carr, look for a strut that has that extended length and the force you came up with in step 1.

3. Check the compressed length of the chosen strut, the mount point for it will be a maximum of the difference between the extended and compressed lengths away from the hinge point. You don't want the strut bottoming out when the hatch is closed, so it's a good idea to make this distance just a bit shorter than the difference.

Those steps should get you appropriate struts for your application.

1. You want struts that will have a bit more force than the load they need to support. The load can be found with a bathroom scale and a stick. Pick a place where you think you'd like to attach the struts, put a bathroom scale on the floor of the trailer, and a stick between that point and the scale. The scale will tell you how much downward force the hatch is exerting at that point. The magenta line in the drawing below shows a weigh point that could be used for this hatch. Let's say the scale reads 40 lbs., two 25-lbs. force struts should do the job nicely, and 30-lb. struts would give a little more margin to protect from winds moving the hatch. (The stick in this photo isn't being used for weight measurement, it's holding up the hatch - this is just an edit of a photo I already had on hand).

2. Measure the vertical length from the attachment point you'd like to use on the hatch to the attachment point you'd like to use on the camper shell. Checking a website like McMaster-Carr, look for a strut that has that extended length and the force you came up with in step 1.

3. Check the compressed length of the chosen strut, the mount point for it will be a maximum of the difference between the extended and compressed lengths away from the hinge point. You don't want the strut bottoming out when the hatch is closed, so it's a good idea to make this distance just a bit shorter than the difference.

Those steps should get you appropriate struts for your application.

jscherb

Expedition Leader

When I went to the junkyard to get the gas struts the other day, I also picked up the rear barn door from an old postal Jeep for $20. Once or twice a year a postal will show up in this junkyard, I've bought several of these doors for other projects in the past.

This door could be used on a Jeep-tub TrailTop with a rear door, although being all steel it's a bit heavy, so you'd need to build the tub and TrailTop appropriately for the weight.

The small inset drawing above is a "Double Dinoot" 8' 3" tub; the photo is my 7' 5" all metal Jeep-tub trailer.

This door could be used on a Jeep-tub TrailTop with a rear door, although being all steel it's a bit heavy, so you'd need to build the tub and TrailTop appropriately for the weight.

The small inset drawing above is a "Double Dinoot" 8' 3" tub; the photo is my 7' 5" all metal Jeep-tub trailer.

jscherb

Expedition Leader

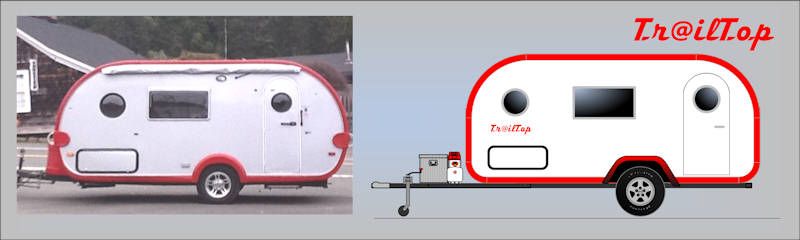

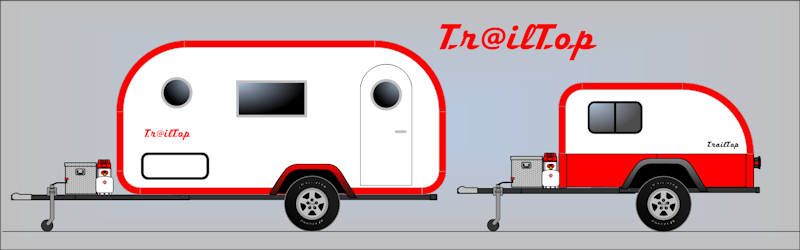

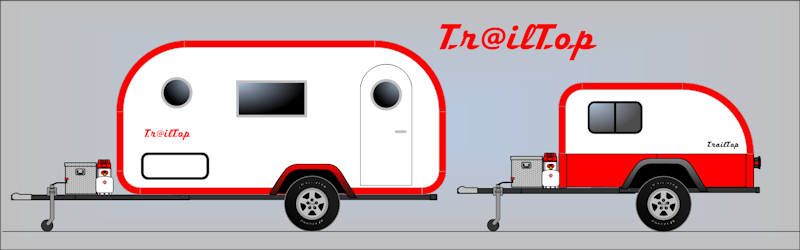

This one's perhaps a bit large to be an expedition trailer...

About two weeks ago on my drive back from Florida I spotted this:

Seemed like a good project for TrailTop parts, so I drew a concept using just the TrailTop parts I've already molded - 36" radius curves, 12" radius curves and 8' straight sections. The concept is basically the same size as the T@DA trailer, so any of the T@DA interior arrangements could be built in it.

Comparing it for size to the TrailTop proof-of-concept prototype:

About two weeks ago on my drive back from Florida I spotted this:

Seemed like a good project for TrailTop parts, so I drew a concept using just the TrailTop parts I've already molded - 36" radius curves, 12" radius curves and 8' straight sections. The concept is basically the same size as the T@DA trailer, so any of the T@DA interior arrangements could be built in it.

Comparing it for size to the TrailTop proof-of-concept prototype:

jscherb

Expedition Leader

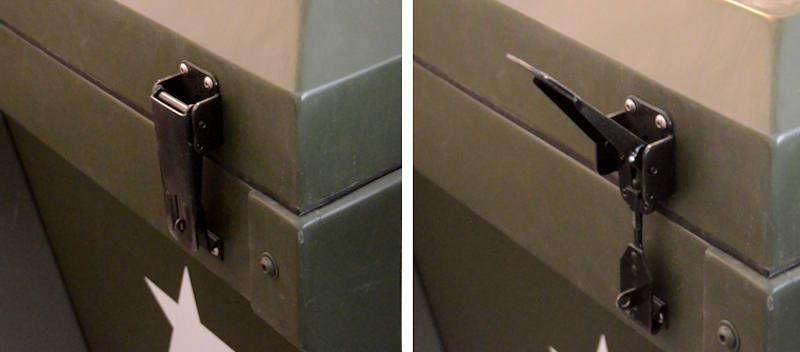

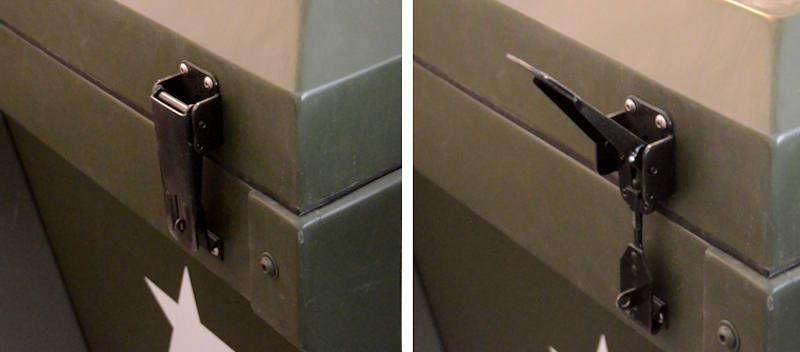

Here are two options I'm considering for latching/locking the hatch.

1. Simple RV-style flip latches. I used these on the cover for the military trailer project and they've worked out really well. The ones I used are adjustable, and they have a hasp for a padlock.

They'd mount like this:

These would be very easy for a DIY installation.

2. A locking T-handle. I used one of these on the front hatch on the Safari Overland Camper prototype.

There's a bit of mechanism inside the hatch to get installed, here's a shot of the inside of the hatch of the Safari camper prototype.

I think I'll probably do the T-handle, although the RV latches are appealing because of their simplicity for the DIY-er.

Your input on this is very welcome, if there's a better option I've missed please let me know.

1. Simple RV-style flip latches. I used these on the cover for the military trailer project and they've worked out really well. The ones I used are adjustable, and they have a hasp for a padlock.

They'd mount like this:

These would be very easy for a DIY installation.

2. A locking T-handle. I used one of these on the front hatch on the Safari Overland Camper prototype.

There's a bit of mechanism inside the hatch to get installed, here's a shot of the inside of the hatch of the Safari camper prototype.

I think I'll probably do the T-handle, although the RV latches are appealing because of their simplicity for the DIY-er.

Your input on this is very welcome, if there's a better option I've missed please let me know.

The T handle is the cleaner, more profesional look to be sure, but I've never installed one so I'm not sure how complicated it might be to get sorted. The simplicity of the RV latches is great, but I don't like the look quite as much on that particular set-up. I think they would look more appropriate on something more 'military' or industrial looking.

jscherb

Expedition Leader

Here's another way to use TrailTop parts... in most of my TrailTop concept drawings I add a cargo box on the tongue of the trailer, and usually I picture that box being made from diamondplate aluminum. But you could easily build a cargo box to match the camper shell using TrailTop parts:

The concept above uses TrailTop parts for the framing and the same panel material as the camper shell, in this case drawn as birch plywood. But you could also use fiberglass Dinoot parts to make the basic box, and TrailTop parts for the top:

The concept above uses TrailTop parts for the framing and the same panel material as the camper shell, in this case drawn as birch plywood. But you could also use fiberglass Dinoot parts to make the basic box, and TrailTop parts for the top:

Similar threads

- Replies

- 3

- Views

- 520

- Replies

- 2

- Views

- 651

- Replies

- 9

- Views

- 388

- Replies

- 9

- Views

- 2K

- Replies

- 0

- Views

- 460