You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"TrailTop" modular trailer topper building components

- Thread starter jscherb

- Start date

bonomonster

Adventurer

When I finally build my trailer, I am trying with the idea of building a kitchen Island that would be on 8" wheels.

Sent from my SCH-I535 using Tapatalk

Sent from my SCH-I535 using Tapatalk

jscherb

Expedition Leader

I have a 5'x8' landscape trailer that I have been thinking of building a removable box for. This would allow me to keep the box loaded up with everything needed for camping, but still have the trailer ready for normal hauling.

Yes, you could do something like this:

Or a teardrop shape, whatever style you liked.

bonomonster

Adventurer

Would the removable camper be "doable" on a 4 x 6 trailer?

I think your only real issue would be lack of interior space

Sent from my SCH-I535 using Tapatalk

jscherb

Expedition Leader

Would the removable camper be "doable" on a 4 x 6 trailer?

I think your only real issue would be lack of interior space

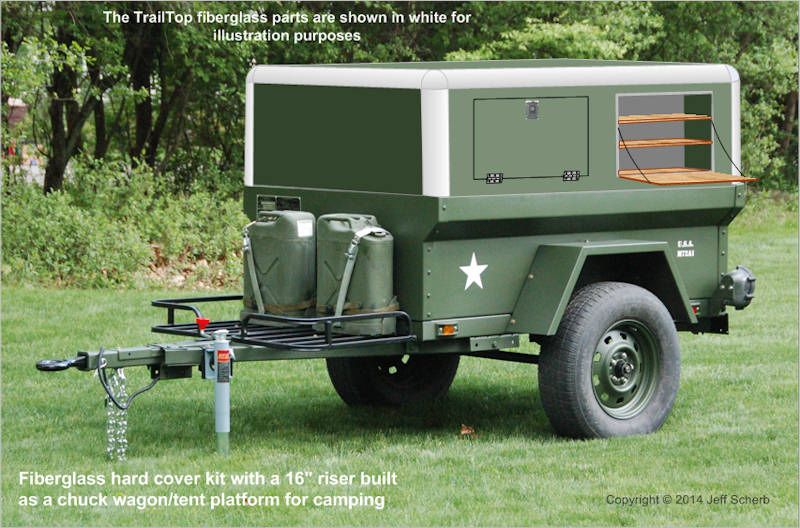

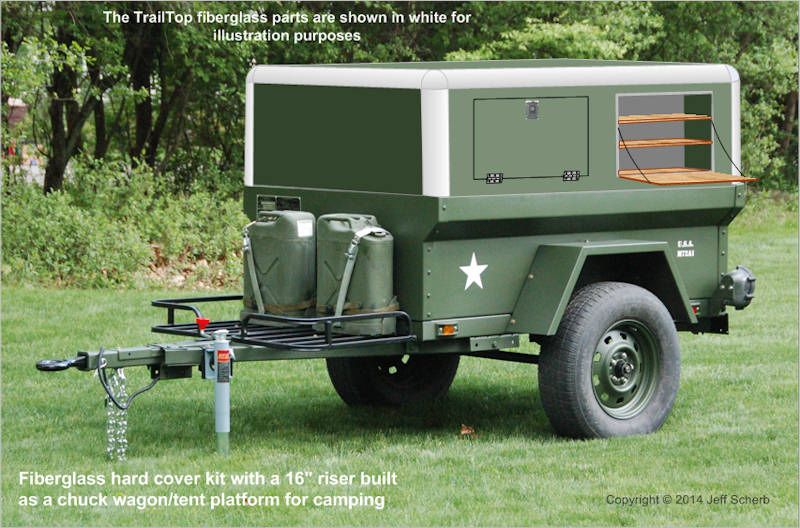

As bono says, a 4x6 trailer is a bit small to make a "sleep-in" camper, but you could make a "sleep-on" camper... here's a camp box that slides onto the 4x6; it's got storage plus compartments to serve as a chuck wagon, and it supports a roof-top tent.

jscherb

Expedition Leader

Speaking of 4x6 trailers, that's the size of the M416's and similar (like the fiberglass Dinoot m-series kits), they are 4x6 at the top, and about 40" x 6 at the floor, so definitely not large enough for a sleep-in camper. A TrailTop cargo top/tent platform can turn those into a camper. You could build a chuck wagon/roof-top tent platform for a military using TrailTop parts. In the illustration below, the TrailTop parts have been left in white for illustration purposes. I haven't installed a roof-top tent in this drawing, I'll leave that to your imagination  .

.

Last edited:

rjinga

Observer

... here's a camp box that slides onto the 4x6; it's got storage plus compartments to serve as a chuck wagon, and it supports a roof-top tent.

Thanks for the cool mock-up. Are (will) the TrailTop parts (be) available?

jscherb

Expedition Leader

Thanks for the cool mock-up. Are (will) the TrailTop parts (be) available?

My pleasure. It's fun for me to take someone's question or design idea and do a concept drawing of it

At the moment, TrailTop is a design experiment/hobby project of mine. I spent today making the main molds for the parts; there's a little more work do do on the molds before I can make actual TrailTop parts, but everything should be ready for molding by the end of this week. Once I've made up some parts, I'll assemble a prototype TrailTop. I'll probably do a teardrop for my Jeep-tub trailer, but I haven't 100% decided on that. In the process of assembling the prototype, I'll decide if any other molds/parts would be a good idea, and if so, I'll make those too (I've got a few other parts in mind, when I get to that point I'll post the ideas for everyone's input). Once the prototype is assembled, I'll decide if I think the design would make a good commercial product, and if so, I'll explore that possibility with the companies that have expressed interest.

Along the way, I'd like to continue to get everyone's input and feedback. Am I missing something? Is there some additional TrailTop part I should be designing/making a mold for? Can the parts I've designed make the types of trailer toppers that you guys would be interested in? Did I get something way wrong? Is TrailTop a stupid idea?

bonomonster

Adventurer

Definitely a great idea.... What about some kind of lower wall to floor trim/bracket?...

Sent from my SCH-I535 using Tapatalk

Sent from my SCH-I535 using Tapatalk

jscherb

Expedition Leader

Definitely a great idea.... What about some kind of lower wall to floor trim/bracket?...

Sent from my SCH-I535 using Tapatalk

Thanks. That's actually one of the parts I'm thinking about. I'm trying to keep the cost of building a TrailTop as low as possible, so my decision criteria is that to be made out of fiberglass a part has to make building a TrailTop significantly easier or make the result more professional. If something would be just as easy to make from wood, or a piece of stock metal, then there may not be a justification for making a fiberglass part.

The main TrailTop side rails are a good example - they make it very quick and easy to frame up a nicely curved shape, and simplify the overall construction while at the same time increasing the strength of the assembly. And because they have nice compound curves, you can achieve a professional looking result in terms of style far easier than you could if you tried to do compound curves like that from scratch in wood or metal.

Anyway, when I get to assembling a prototype TrailTop, I'll be posting all of the details of the construction and I'll be asking questions about additional parts, so please stay tuned and keep adding your input.

jscherb

Expedition Leader

How are you planning to hook all of the pieces together? Fiberglass to fiberglass, fiberglass to wood, overall coating once assembled?

The TrailTop parts have a tab system; each of the corners have tabs that the straight rails overlap with. There are several ways to join them:

- Bolts. Good if you plan to disassemble things.

- Fiberglass. A layer of fiberglass mat saturated with resin between the parts will form a permanent bond.

- Adhesive. A number of adhesives can be used, including epoxy and construction adhesive.

- Body filler. Body filler is basically polyester resin (the same resin as used in fiberglass) with fillers added. Because the TrailTop fiberglass parts and body filler are based on polyester resin, they're 100% compatible and bond very well. And because of its consistency, body filler makes a good gap filler in case there's a less-than-perfect fit between parts. There are "high grip" varieties of body filler that are probably better than some of the "ez-sand" varieties for this application. Body filler is my personal favorite for bonding TrailTop parts

.

.

Side panels get bolted to the recessed flanges provided on all of the TrailTop parts. The joint can be weatherstripped in multiple ways - EDPM rubber works well if you ever plan to disassemble the parts; there are various sealing compounds that work well for more permanent joints.

Overall coating depends on your choice of materials. The fiberglass TrailTop parts don't need an additional coating, but since they'd probably be molded in white, if you wanted a different color you could paint them. If you make the side panels from plywood, as I imagine most builders would, standard sealing/painting techniques that are commonly used with DIY-built campers or boats would be appropriate. If you decided to use something other than plywood for the sides, the final finish would depend on the material you chose. For example, polypropylene laminate wouldn't need any finish; fiberglass sandwich panels also wouldn't need any finish, although the wood core variety would need to have the edges sealed. Similarly, aluminum laminate panels with a birch or luan plywood core would also only need sealing at the edges.

Similar threads

- Replies

- 3

- Views

- 520

- Replies

- 2

- Views

- 649

- Replies

- 9

- Views

- 380

- Replies

- 9

- Views

- 2K

- Replies

- 0

- Views

- 460