You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Unicorn on the Ocean - 1120AF Coming to Canada

- Thread starter whomisi

- Start date

whomisi

Active member

Whatever you do, do NOT put the spare on the cab roof. You won't be able to tip the cab, the weight will damage the cab, even if mounted on a frame as ours was. Then, too, is the need for a crane. When I bought the truck the spare was on the cab roof. Looked cool and I even unloaded it with the crane. Terrible, terrible idea.

Simply make your box large enough. Extending the box is cheap and easy. Hanging a frame/carrier on

I do get what you're saying. My initial plan was to cut down a full DOKA cab, which I figured would need extra weight for the cab suspension to work properly as it isn't loaded with firefighters. I'll have to look up the specs for our cab, if it could even handle the weight. The height on top of the cab isn't all that different to where people usually carry them on the back of the truck. How heavy even is a mounted 385/65/22.5? 150kg?

As to putting it inside the box, I think it would be hard to figure a loading mechanism that doesn't damage any entryway, especially a side mount. And I don't want anything on the rear of the box to open as I know how filthy and prone to dust ingress anything at the back is. I think the rear mounted lifting systems aren't that complex and don't have to be that heavy, so for my single spare I think this might be my best option.

I'd be happy backing the spare into bushes more than a longer box when in the forest! And anything over 18ft box would be looking a little funky even with the extended wheelbase.

About the subject of spare tires, if you have a common size like 385/65R22.5, a single decent spare is ok.

However, if you decide to use MPT/military 20” tires, I recommend carrying a second unmounted spare.

They aren’t common in any part of the world. If bad luck strikes and a tire is irreparably damaged, and you are thrust into a situation with NO spare tire, your trip transforms into a search for tires instead of a vacation. One of those “don’t ask me how I know” things.

Regarding DiploStrat’s roof rack on cab comment, I’d suggest a modification. I consulted the bodybuilder manual for my chassis, which has a hydraulic cab tilting ram built in (naturally I carry the 30mm socket required). The manual specified certain mounting points and and a max load of 80kg (<20kg/mounting point)

Unicat (the vehicle was in Germany at the time) built a lightweight rack and mounted 2 aluminum boxes which store bulky lightweight items: kinetic ropes and spare wastewater hose.

A spare unmounted tire would have exceeded the specifications.

I've chosen the common size you mention. I was a little back and forth and then kept seeing that tyre size on trucks all around where I live and figured the loss in air-down-ability was a small price to pay to avoid the struggles you mention. And yes, I'll be able to carry one spare. Especially if I keep the 18k lbs hydraulic winch, getting stuck might not be such an issue. I'll have to look up the specs on my roof, even if the tyre isn't up there, I want to know what kind of rack I should build. I like the one on that "example" truck I put the photo on a few posts back. Although I would probably add bars down the A pillars for branch deflection. I know where I'll be taking this thing.

Very nice truck. And with ABS-Brakes !

!

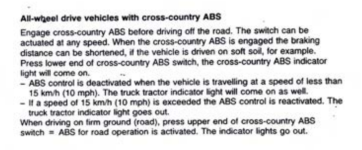

Yes! Is this unusual? It comes with a button and FOUR dash lights. I have no idea what they mean or do. I think it's something about turning ABS off for lower speed offroad stuff?

And is the "flame starter" (looks like glow plug symbol) reliable? Does anyone have experience with this?

charlieaarons

Explorer

I had a flame starter with my Perkins 4.236. It worked ok in cold weather.

Geo.Lander

Well-known member

I do get what you're saying. My initial plan was to cut down a full DOKA cab, which I figured would need extra weight for the cab suspension to work properly as it isn't loaded with firefighters. I'll have to look up the specs for our cab, if it could even handle the weight. The height on top of the cab isn't all that different to where people usually carry them on the back of the truck. How heavy even is a mounted 385/65/22.5? 150kg?

As to putting it inside the box, I think it would be hard to figure a loading mechanism that doesn't damage any entryway, especially a side mount. And I don't want anything on the rear of the box to open as I know how filthy and prone to dust ingress anything at the back is. I think the rear mounted lifting systems aren't that complex and don't have to be that heavy, so for my single spare I think this might be my best option.

I'd be happy backing the spare into bushes more than a longer box when in the forest! And anything over 18ft box would be looking a little funky even with the extended wheelbase.

I've chosen the common size you mention. I was a little back and forth and then kept seeing that tyre size on trucks all around where I live and figured the loss in air-down-ability was a small price to pay to avoid the struggles you mention. And yes, I'll be able to carry one spare. Especially if I keep the 18k lbs hydraulic winch, getting stuck might not be such an issue. I'll have to look up the specs on my roof, even if the tyre isn't up there, I want to know what kind of rack I should build. I like the one on that "example" truck I put the photo on a few posts back. Although I would probably add bars down the A pillars for branch deflection. I know where I'll be taking this thing.

View attachment 800162

Yes! Is this unusual? It comes with a button and FOUR dash lights. I have no idea what they mean or do. I think it's something about turning ABS off for lower speed offroad stuff?

And is the "flame starter" (looks like glow plug symbol) reliable? Does anyone have experience with this?

View attachment 800163

You have a glow plug on the inlet manifold like mine, and ABS was fairly common up in the north of the EU for trucks late 80s and early 90s. The ABS switch from the manual is below, it is called cross country ABS mode.

I am not sure the argument about cab suspension for the spare on the roof pans out, these 1.5 cabs were designed to carry 6 firemen. The Cab-tilt of course is another story, I also need to do some reserach about this, but I will only have gear up there and a decking and will fit space for my spare somewhere else. I might ditch the spare rim too and just carry some pry bars... Yes it is possible

There is also the option of carrying the spare under the rear or between the chassis rails. As is factory.

I was also considering brush bars over the front window arches of the truck, but I will for the moment just fit some 3M clear wrap and maybe some wire later on.

Geo.Lander

Well-known member

When are you shipping the truck? You should change into new wheels and tires before you ship it over otherwise the fright costs for the super singles is crazy...

whomisi

Active member

Oh I don't know why I thought it was a flame starter, I must have seen something somewhere.... I don't recall.When are you shipping the truck? You should change into new wheels and tires before you ship it over otherwise the fright costs for the super singles is crazy...

Do 42" tyres fit between the rails? I assumed that the bigger tyres wouldn't fit. I don't have room anyway, unless I ditch the winch.

English user manual! Where did you find that?! I've been translating a german one I downloaded, and it isn't very easy to process. Thanks for sharing the ABS info.

Well right now she's off the south coast of the UK, with 5 rims already inside (11JR22.5ET110) (I will buy tyres in Canada when the conversion is complete). I grew up in Littlehampton, it is funny how close and yet how far the truck is from my growing up area haha.

charlieaarons

Explorer

A flame starter actually drips diesel onto a red hot electrically heated coil and bursts into flame when air flow starts with cranking.

The OM906LA, at least, has an electrical grid heater, no fuel involved.

Don’t know about 366. I’ll make a bet both were used at various times.

The OM906LA, at least, has an electrical grid heater, no fuel involved.

Don’t know about 366. I’ll make a bet both were used at various times.

Last edited:

DiploStrat

Expedition Leader

Pity the truck is already en route. Given the dearth of service options in North America, would strongly recommend a spa week at Atkinson Vos or one the similar companies in Holland or Germany.

There is so much that you simply cannot get done right in North America.

The week that our truck spent at Atkinson Vos simply transformed it.

There is so much that you simply cannot get done right in North America.

The week that our truck spent at Atkinson Vos simply transformed it.

DiploStrat

Expedition Leader

" I think the rear mounted lifting systems aren't that complex and don't have to be that heavy, so for my single spare I think this might be my best option. "

Methinks that is because you haven't looked at one. In my case, the advantage is that the tire carrier is mounted to the frame only and does not stress the box.

If you do mount externally, then talk to Andreas and order the specific, reinforced panel that he sells. You don't want to pull the back off of your truck on a dirt road.

Also, the further aft and higher you go, the greater the cantilever effect. Think tail wagging dog.

Methinks that is because you haven't looked at one. In my case, the advantage is that the tire carrier is mounted to the frame only and does not stress the box.

If you do mount externally, then talk to Andreas and order the specific, reinforced panel that he sells. You don't want to pull the back off of your truck on a dirt road.

Also, the further aft and higher you go, the greater the cantilever effect. Think tail wagging dog.

mog

Kodiak Buckaroo

I found one for my MB1017 on the English eBay site ( https://www.ebay.co.uk/b/bn_2314766 ). It was around $50 USD including shipping to the USA.English user manual! Where did you find that?! I've been translating a german one I downloaded, and it isn't very easy to process. Thanks for sharing the ABS info.

Last edited:

whomisi

Active member

I understand your concern, but I'm quite happy to go over this myself and wait for the parts. With the especially good condition of this vehicle, and my interest in learning every bit of it, I'd rather do it myself than pay someone else.Pity the truck is already en route. Given the dearth of service options in North America, would strongly recommend a spa week at Atkinson Vos or one the similar companies in Holland or Germany.

There is so much that you simply cannot get done right in North America.

The week that our truck spent at Atkinson Vos simply transformed it.

As I'm making my own 4pnt habitation subframe, I don't feel it is too complicated to tie a carrier into the subframe reducing the vertical load burden on the box. I'm certainly not just bolting a heavy wheel to a foam/fiberglass panel.

Perhaps my ignorance is getting the better of me and I'll soon learn the hard way!

My only "build" experience thus far was our Vanagon Westfalia for a South America trip. DIY Subaru engine swap, customs bumpers including swing out, full mechanical overhaul. A little detail on our blog for anyone interested. We made Canada to Ushuaia and back to Valparaiso in 9 months. Far too quick.

Westy Rick, the making of

Warning, contains entirely boring mechanical themes which will not be interesting for most readers. Here we briefly detail how Westy R...

whomisi

Active member

Good to know, my Dad is flying out to join me for the cross Canada road trip. Would save me some shipping. I'll have a look, thank you.I found one for my MB1017 on the English (GB) eBay site. It was around $50 USD including shipping to the USA.

DiploStrat

Expedition Leader

You will do well. Problem is that many of the parts are simply no longer available, even in Europe. (I was surprised.)I understand your concern, but I'm quite happy to go over this myself and wait for the parts. With the especially good condition of this vehicle, and my interest in learning every bit of it, I'd rather do it myself than pay someone else.

As I'm making my own 4pnt habitation subframe, I don't feel it is too complicated to tie a carrier into the subframe reducing the vertical load burden on the box. I'm certainly not just bolting a heavy wheel to a foam/fiberglass panel.

Perhaps my ignorance is getting the better of me and I'll soon learn the hard way!

My only "build" experience thus far was our Vanagon Westfalia for a South America trip. DIY Subaru engine swap, customs bumpers including swing out, full mechanical overhaul. A little detail on our blog for anyone interested. We made Canada to Ushuaia and back to Valparaiso in 9 months. Far too quick.

Westy Rick, the making of

Warning, contains entirely boring mechanical themes which will not be interesting for most readers. Here we briefly detail how Westy R...westygoessouthy.blogspot.com

Build the tire to the frame, not the sub-frame. You want the later to be as light as possible. Mine was over built. Won't complain, but could have used a bit less weight. I prefer the frame on frame with pull out springs, as used by Bimobil and, I think, Unicat.

Post lots of pictures and we will send lots of good thoughts your way. And stock your favorite adult beverages; you will need them.

Final suggestion, build your camper electrical system at 24v (inverter/charger, batteries, B2B, etc.) to match the truck and add a step down transformer at the end. Much easier.

Geo.Lander

Well-known member

I understand your concern, but I'm quite happy to go over this myself and wait for the parts. With the especially good condition of this vehicle, and my interest in learning every bit of it, I'd rather do it myself than pay someone else.

As I'm making my own 4pnt habitation subframe, I don't feel it is too complicated to tie a carrier into the subframe reducing the vertical load burden on the box. I'm certainly not just bolting a heavy wheel to a foam/fiberglass panel.

Perhaps my ignorance is getting the better of me and I'll soon learn the hard way!

My only "build" experience thus far was our Vanagon Westfalia for a South America trip. DIY Subaru engine swap, customs bumpers including swing out, full mechanical overhaul. A little detail on our blog for anyone interested. We made Canada to Ushuaia and back to Valparaiso in 9 months. Far too quick.

Westy Rick, the making of

Warning, contains entirely boring mechanical themes which will not be interesting for most readers. Here we briefly detail how Westy R...westygoessouthy.blogspot.com

When building the 4 point subframe Keep the central pivot floating to allow real world articulated tests, we had to adjust our central chucks quite a bit after the design phase.

Similar threads

- Replies

- 6

- Views

- 984

- Replies

- 5

- Views

- 2K

- Replies

- 2

- Views

- 2K