jscherb

Expedition Leader

I've been using marine deep cycle lead-acid batteries to power the fridge and campsite accessories in my two expedition Jeeps for a number of years and they've served me very well. I buy them at Walmart, they're under $100 and all but the last one I had lasted until the end of the three year warranty. In October 2022 the battery kitchen battery in my JKU started failing, it lasted 35 months, so I replaced it with another Walmart battery. They had changed the warranty to one year, which I didn't think that much about since I've had good luck with these batteries in the past. Apparently they really mean it, because the most recent battery failed in November 2023 after only 13 months. They probably changed the warranty because they apparently cheapened the battery. That story is a long way to getting around to saying I've been thinking maybe I should switch to lithium batteries or switch to deep-cycle batteries of better quality not from Walmart. Side note: why have I always bought them from Walmart? Because wherever I am in the country, if a battery fails while on a trip or expedition, there's always a Walmart somewhere to get a warranty replacement. And they're reasonably priced if I have to buy a new one out of warranty.

By a strange coincidence, at the same time I deciding to replace that last lead-acid battery, Lightning New Energy contacted me, wondering if I would be interested in testing their new lithium battery. Perfect timing, so I agreed and they sent me one to test.

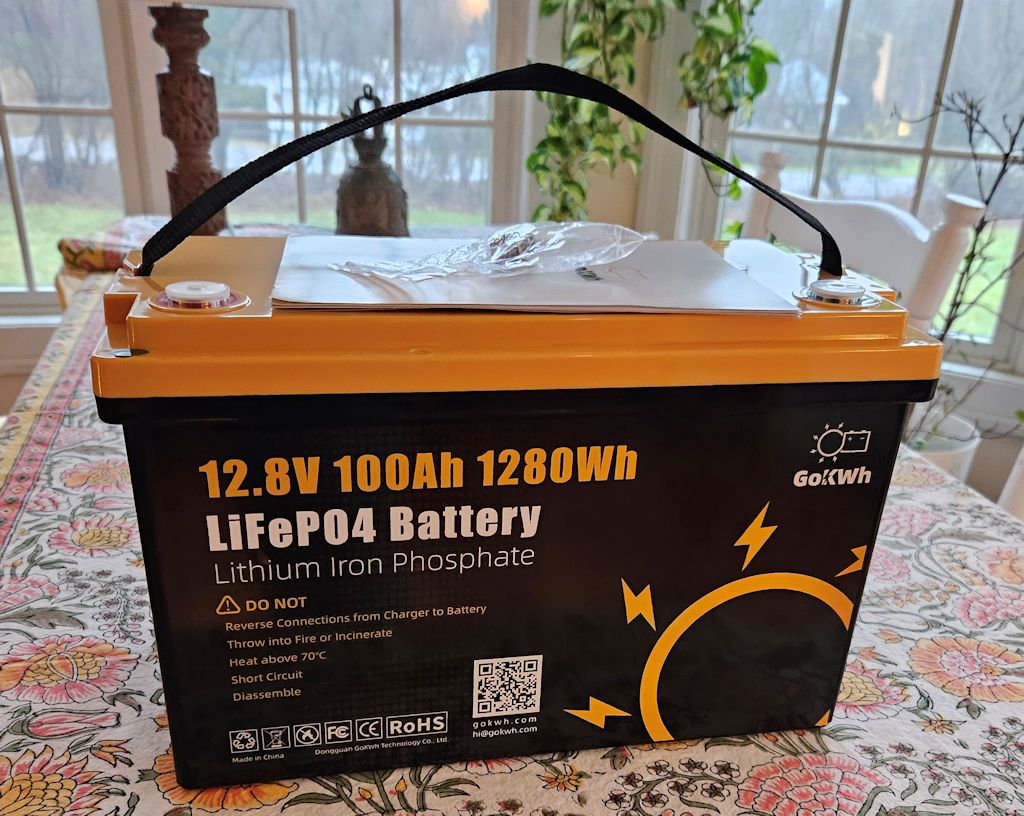

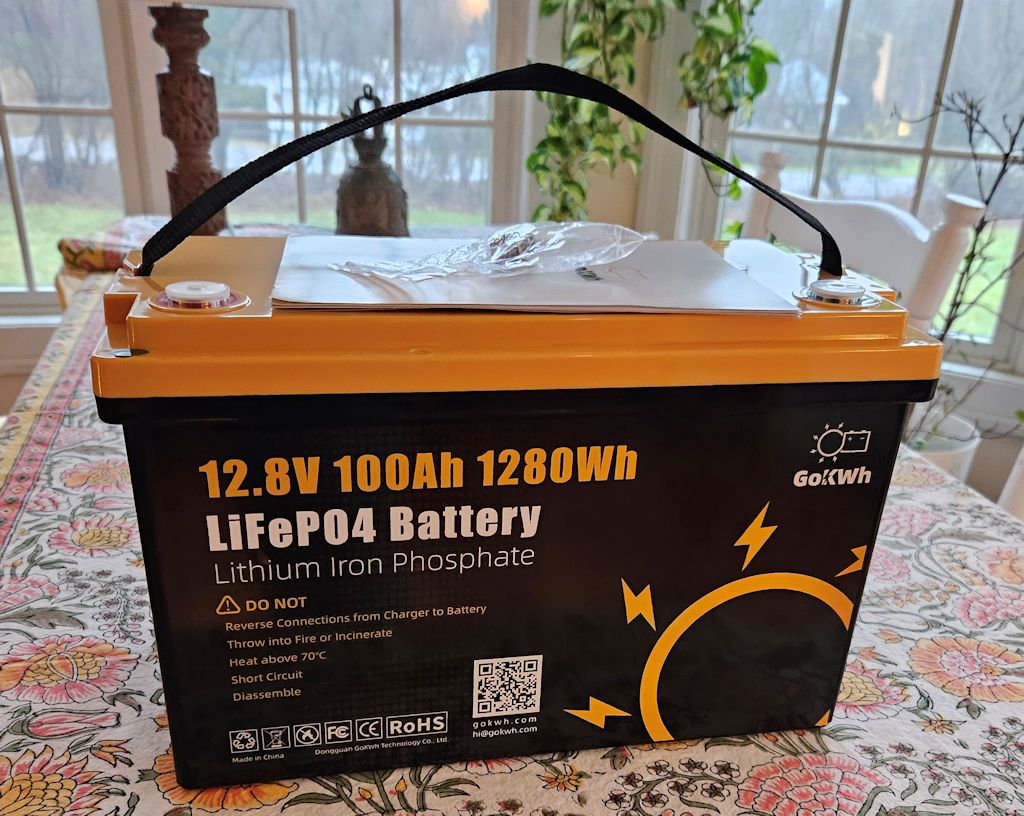

Their lithium battery arrived in January:

The battery is 12V, 100Ah and uses LiFePO4 chemistry (Lithium Iron phosphate). LiFePO4 batteries are a type of lithium ion rechargeable batteries, their benefits over the more traditional cobalt-based lithium-ion batteries are increased power output, faster charging, reduced weight and longer lifetime.

I've been experimenting with the battery since it arrived and the following posts document the result of my testing and research on using Lithium batteries.

By a strange coincidence, at the same time I deciding to replace that last lead-acid battery, Lightning New Energy contacted me, wondering if I would be interested in testing their new lithium battery. Perfect timing, so I agreed and they sent me one to test.

Their lithium battery arrived in January:

The battery is 12V, 100Ah and uses LiFePO4 chemistry (Lithium Iron phosphate). LiFePO4 batteries are a type of lithium ion rechargeable batteries, their benefits over the more traditional cobalt-based lithium-ion batteries are increased power output, faster charging, reduced weight and longer lifetime.

I've been experimenting with the battery since it arrived and the following posts document the result of my testing and research on using Lithium batteries.