FaronFaulk

New member

We have a Warn 16.5ti winch on our GXV AT (~20k lbs)

I'd like to switch to a synthetic line.

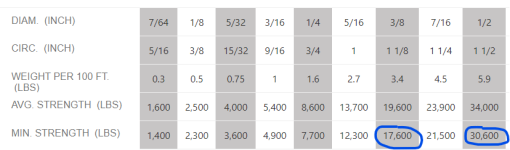

The Warn Spydura Pro 3/8" says it's rated to the 16.5k lb capacity of the winch.

The Yankum 1/2" says it's 30,600 lb MTS, so I feel like we're comparing apples to oranges.

Any idea which actually has more strength?

Are there other brands we should be considering?

thanks,

Faron

I'd like to switch to a synthetic line.

The Warn Spydura Pro 3/8" says it's rated to the 16.5k lb capacity of the winch.

The Yankum 1/2" says it's 30,600 lb MTS, so I feel like we're comparing apples to oranges.

Any idea which actually has more strength?

Are there other brands we should be considering?

thanks,

Faron