You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What multi axis hitch do you prefer?

- Thread starter Borrego60

- Start date

R_Lefebvre

Expedition Leader

I've been thinking about how to make my own coupler, tossing around various ideas in my head. I never even thought about the binding, but Elmo's post really makes it clear. Very interesting.

One idea I had was to use two large spherical bearings attached together, kind of like a dogbone, but rotated 90° out of phase. The only problem is, it's almost too many degrees of freedom. I think when braking, or backing up, the dogbone would just twist out of position and cause a problem.

It's an interesting engineering problem this. We need many degrees of freedom to prevent binding, but not too many because that causes other problems.

One idea I had was to use two large spherical bearings attached together, kind of like a dogbone, but rotated 90° out of phase. The only problem is, it's almost too many degrees of freedom. I think when braking, or backing up, the dogbone would just twist out of position and cause a problem.

It's an interesting engineering problem this. We need many degrees of freedom to prevent binding, but not too many because that causes other problems.

adventureduo

Dave Druck [KI6LBB]

We use the Lock N Roll on our trailer. Ours too is bent from a jackknife. It works good still, just make sure to lube the points regularly. If i had the denero , i would consider switching to the Max Coupler.. but for now the Lock N Roll works fine. The one thing i like about the Lock N Roll is that it doesn't have any rubber. I hate poly anything. Always seems to wear.

Mario, funny...weren't we just having a coupler 101 class yesterday? lol

Mario, funny...weren't we just having a coupler 101 class yesterday? lol

go4aryd

Adventurer

It's an interesting engineering problem this. We need many degrees of freedom to prevent binding, but not too many because that causes other problems.

The root problem for all the binding issues I have seen really only occurs in backing up - where the hitch is too flexible to avoid over-rotation and resultant binding. The only real solution is a more rigid coupling when reversing direction. The pintle/lunette arrangements is necessarily stiff, and thus really cannot bind (just rubs, clanks, bangs, and otherwise annoys all around).

The Max Coupler actually looks to be an interesting design in this respect, in that it limits the degrees of freedom in reverse. Of course, if you jack knife the trailer, you are probably going to damage the rotating pins. But the lack of a flexible link between rig and trailer should really help minimize binding potential.

Martyn

Supporting Sponsor, Overland Certified OC0018

The root problem for all the binding issues I have seen really only occurs in backing up - where the hitch is too flexible to avoid over-rotation and resultant binding. The only real solution is a more rigid coupling when reversing direction. The pintle/lunette arrangements is necessarily stiff, and thus really cannot bind (just rubs, clanks, bangs, and otherwise annoys all around).

The Max Coupler actually looks to be an interesting design in this respect, in that it limits the degrees of freedom in reverse. Of course, if you jack knife the trailer, you are probably going to damage the rotating pins. But the lack of a flexible link between rig and trailer should really help minimize binding potential.

From personal experience I can attest to the fact that an inflexible ball coupler can also be bent due to jack knifing.

That would lead me to believe it's inherant in the reversing and angle rather than the flexibility. Once a tight enough angle is reached the rotation stops and the forces go in an other direction.

The idea that a pintle doesn't bind is misleading. A non-rotational pintle gives 45° of movement until it binds up, a rotational pintle allows for more, but in a jack knife situation even the rotational pintle binds.

What stops the pintle from distorting is the fact it's massive and cast. The question you have to then ask yourself is where is this force then transmitting.

In the Lock-n-Roll it's distorting the coupler, we know the coupler has been tested up to 18000 lbs (3 times it's rating), so with the pintle where is the 18000 lbs of force going?

The answer I believe is it's being transmitted into the chassis of the trailer, the hitch or rear bumper or both.

What's easier to replace? What's the least expensive part? What is acting as the safety valve? What's easiest to repair in the field? The coupler.

R_Lefebvre

Expedition Leader

In the Lock-n-Roll it's distorting the coupler, we know the coupler has been tested up to 18000 lbs (3 times it's rating),

I would think the test was a straight on pull? The LnR coupler is bending with much less than 18k lbs in this case. When it binds, the forces are being applied in a way the manufacturer didn't intend.

go4aryd

Adventurer

I would think the test was a straight on pull? The LnR coupler is bending with much less than 18k lbs in this case. When it binds, the forces are being applied in a way the manufacturer didn't intend.

No doubt.

BTW I have also seen bent Lunettes and Pintles. They will bend if caught just right (90 right angle with an up or down angle can cause the ring to catch and torque on the pintle = bad news and no field fix unless you carry these as heavy spares).

From personal experience I can attest to the fact that an inflexible ball coupler can also be bent due to jack knifing

Yes that is true - but the question I ask is why. When we use the term "jack knife" some of us are talking about the position of the trailer relative to the rig vs actual contact and damage due to contact with the rig. I have never seen a ball coupler get bent due to binding without contacting the tow rig from the side as well as the hitch. The ball, on the other hand, can get torn all to heck (as well as bending the ball retainer plate).

Is that what you mean? If not, please elaborate so we can visualize the forces leading to the failure.

Last edited:

gabepari

Explorer

Having used the Max Coupler, and having walked along a trailer and watched the coupler closely during extreme maneuvers, I will say that it isn't very "impressive" to watch. It works so well that it doesn't even look like it is doing anything. Even with the trailer all tangled up behind the TV, the coupler never showed any signs of binding or compromising positions that could lead to possible failure. It is such a simple design that just plain works.

A video, unless it was a side by side comparison wouldn't show much, for the simple fact that there is no drama when the coupler is doing it's thing.

I like it, wouldn't run anything else.

Gabe

A video, unless it was a side by side comparison wouldn't show much, for the simple fact that there is no drama when the coupler is doing it's thing.

I like it, wouldn't run anything else.

Gabe

Martyn

Supporting Sponsor, Overland Certified OC0018

I would think the test was a straight on pull? The LnR coupler is bending with much less than 18k lbs in this case. When it binds, the forces are being applied in a way the manufacturer didn't intend.

I'll get the specs on the test and let you know.

Martyn

Supporting Sponsor, Overland Certified OC0018

No doubt.

BTW I have also seen bent Lunettes and Pintles. They will bend if caught just right (90 right angle with an up or down angle can cause the ring to catch and torque on the pintle = bad news and no field fix unless you carry these as heavy spares).

Yes that is true - but the question I ask is why. When we use the term "jack knife" some of us are talking about the position of the trailer relative to the rig vs actual contact and damage due to contact with the rig. I have never seen a ball coupler get bent due to binding without contacting the tow rig from the side as well as the hitch. The ball, on the other hand, can get torn all to heck (as well as bending the ball retainer plate).

Is that what you mean? If not, please elaborate so we can visualize the forces leading to the failure.

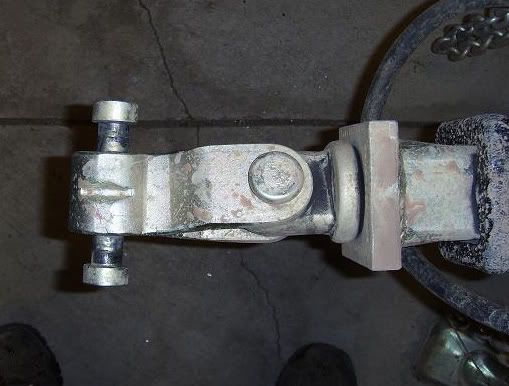

You can see the same bend in the pressed steel coupler that you can see in the Lock-N-Roll

R_Lefebvre

Expedition Leader

The ball coupler appears to have been bent after the truck/trailer were truly jack-knifed, with the bodies touching, and the driver kept backing up.

By comparison, it appears to me that the LnR can bend not from a true jack-knife, but merely by backing up too far, then pulling forward. It's not a stress from body contact, but just because the coupler gets out of alignment.

By comparison, it appears to me that the LnR can bend not from a true jack-knife, but merely by backing up too far, then pulling forward. It's not a stress from body contact, but just because the coupler gets out of alignment.

elmo_4_vt

Explorer

The ball coupler appears to have been bent after the truck/trailer were truly jack-knifed, with the bodies touching, and the driver kept backing up.

By comparison, it appears to me that the LnR can bend not from a true jack-knife, but merely by backing up too far, then pulling forward. It's not a stress from body contact, but just because the coupler gets out of alignment.

That is EXACTLY the point I was trying to make... Although, not being the best writer, I'm sure I wasn't helping people very much. There doesn't have to be any trailer to truck contact, even getting close to 90 Deg will produce the same effects when you try to pull forward without corrective action.

-

Martyn

Supporting Sponsor, Overland Certified OC0018

The ball coupler appears to have been bent after the truck/trailer were truly jack-knifed, with the bodies touching, and the driver kept backing up.

Sorry Rob but that was not the case.

The truck and trailer never touched, in fact there was plenty of room between the rear bumper and the trailer. The angle between the two was quite tight, and all of this was done in the parking lot of a supermarket, driving at a walking pace.

R_Lefebvre

Expedition Leader

I'm not seeing how that's possible. Any pics of the situation? I'm pretty good with visualizing these things, I can see the bind in the LnR, but not the ball coupler. Must have been something unusual happened, because I go 90° on my trailers often and never had a problem.

Edit: Was it a heavy tandem axle? I could maybe see that.

Edit: Was it a heavy tandem axle? I could maybe see that.

Forum statistics

Members online

- driveby

- rruff

- shortbus4x4

- mark5280

- Roam.Wild

- ExpoMike

- willythumbs

- STREGA

- Hun

- momotojin

- Rancid

- kjkeiter

- chet6.7

- xleratin

- MotoDave

- Wegettoadventure

- twowheels19

- deeppurpleman

- Long Rifle

- 85_Ranger4x4

- kerouac

- mmth_ski_bum

- TrailsLessTaken

- RobH7

- furbucket

- igrip

- sabjku

- Mikeythelumberjack

- wingate

- CobraChicken

- rmance

- NorthIdmark

- matttahoe53

- arveetek

- outforarip

- buyrovers

- shawner2713

- robtbritn

- scottrinne

- jmc0369

- Euro6

- highwest

- TexasStevo

Total: 1,532 (members: 47, guests: 1,485)