It's been a while since I posted here. Things I've gotten done:

Bought Coosa board for the floor and bed platform. It's glass fiber reinforced polyurethane foam, used in boat building as a plywood replacement in transoms. It's expensive, but will not rot and only absorbs a tiny bit of water, precluding most mold issues.

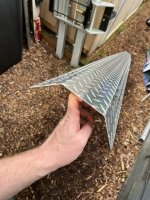

It took a while to figure out how I was going to attach the boards to the frame. I wanted some kind of blind fastener so I didn't need to have a helper under the truck holding a nut. There are options like Nutserts or rivnuts, but I needed a little bit of float on the fasteners so I can hit the holes. I settled on

clip nuts (u-nuts). They have a little retention device that fits in a 10mm hole (for a 6mm fastener). I wanted a little float, so I can pull that hole to 11mm and not affect the nut. The threaded portion of the nut is squeezed a little to act as a locking feature. This is common in the aircraft industry.

I cut and drilled the coosa board, creating a lot of unpleasant dust. I painted the boards to reduce fiberglass splinters and dropped them in. The floor in the camper has 6 Ltracks from fore to aft to be used as the primary mounts for any cabinetry I add later. The floor is held in by a bunch of 6mm screws through these tracks into clipnuts underneath.

There was an issue with window sizing. I'm using arctic tern windows, and I thought I could fit a 300x700 under the bed platform overhang inside the camper, but there was no space for the shade assembly on the inside. I did some measuring, and I could easily mod the window opening for a 300x500 window just by adding a new vertical brace, and everything else would fit. I was able to exchange the window at Tern Overland, which was great. It wasn't free, but it was worth the effort.

All of the welds have been ground and cleaned up. I can get the material to stick together, but it's not always pretty. I had to add a bunch of little mounting points throught the frame for lift mechanism bits, external mounts, lighting, etc... It took forever to figure out and get together.

I've been perseverating over the lift mechanism. My first idea was to use a smallish boat winch hooked up to a scissor lift. I would run the cable from the sides of the pop-top to the back of the camper and the winch would pull up the pop-top. I liked the mechanical aspect of this design, no power, simple, etc... but routing the ropes would be tricky and would leave them exposed in the camper. The slides also take up space in the interior, and need a bunch of extra bracketry to attach to the primary structure.

The next idea was a couple of linear actuators pushing the scissor mechanism to open the top. This solved the rope routing issue but introduced the need for power, mounting large actuators, custom brackets, careful alignment, etc...

I'm starting to think about a set of gas struts and a simple locking lever mechanism inside. It's tried and true and relatively easy. I don't like having the gas struts hanging outside the truck to create wind resistance and maybe get scraped off by a low-hanging branch, but it's looking like a pretty good compromise. There's a reason most of the big companies do it this way.

If I can find some dry weather in Seattle, I will start skinning the camper. All the welding is done and cleaned up. All the windows and doors test fit. I guess I still need to create fillets for the window openings, but that's easy.