South East Backcountry Discovery Route

Part Two of Three

I had a decision to make: all the weather forecasts I sourced warned of a historic winter storm obliterating the mountainous area of eastern Tennessee and western North Carolina in the coming days. I read this objectively, realizing the role of news organizations is not necessarily to provide accurate and useful information as much as to make money for shareholders. I spent hours researching maps, examining routes for the next few days, and estimating descent times from any spot to a nearby town or village for shelter. I considered remaining in the mountains with enough food, water, and fuel for my diesel heater, but though it sounded rugged and romantic, staying in unfamiliar terrain with limited cellular service amounted to an unnecessary risk.

Tucked along a quiet mountain road in Collettsville, North Carolina, Betsey’s Ole Country Store feels like a step back into a gentler, slower-paced past. Housed in a weathered building rooted in the early 1900s, it carries the spirit of old Mortimer, where front-porch conversations and neighborly stops defined daily life. Today, it’s a beloved spot for locals and travelers, offering simple staples, cold drinks, and nostalgic hot dogs to hikers, anglers, and wanderers heading for Wilson Creek and Pisgah National Forest. With creaking floors, mountain backdrop, and timeless hospitality, Betsey’s isn’t just for provisions - it’s a living memory of rural Appalachia and small-town North Carolina’s charm.

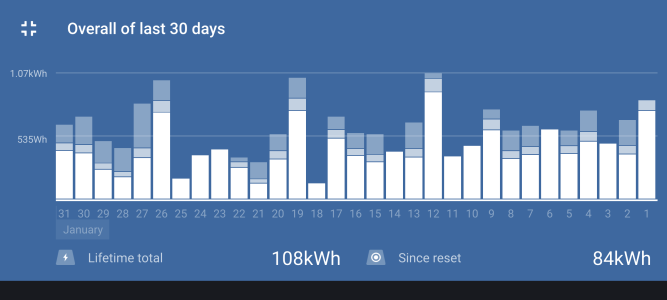

Nestled high in the Blue Ridge, Newland marked a quiet threshold along the SEBDR, transitioning from Section Ten to Nine - I’d completed 148 of 1,300 miles. Normally, it might invite a slower pause: a warm meal, a lingering look at darkening ridgelines. But that night, pressure mounted with a massive winter storm hours from engulfing the region. To stretch progress before conditions worsened, I rolled into a gas station minutes before 2300, likely their last customer under humming fluorescent lights. I refueled the truck and, breaking habit, grabbed energy drinks for alertness if the trail demanded more. Necessity, not comfort, guided the stop.

Just over two hours later, deep into the night, a seasonal gate stopped me - the GPX file from Backcountry Discovery Routes showed it closed December through mid-March, but I tried anyway. I understood the closure: elevation rose quickly to just under a mile high, with annual snow making it too dangerous open. Secretly, I’d envisioned the gate ajar, stopping to install my 140-pound PEWAG 8.2 mm square-link chains on 37x12.5 tires, crawling through tank-like at a few miles per hour. My concern? Crossing the highland only to hit a locked opposite end. Imagine turning a twenty-foot vehicle around on a ten- to fourteen-foot snow-packed shelf road after fourteen hours’ drive? That wouldn’t be fun - I’d likely park and wait for daylight. The closed gate was strike one; two more along the SEBDR meant scrubbing the mission for another time. At only 15% in, odds weren’t favorable, but I’d take the chance.

I studied my maps, dropped off the mountain, and found a detour for the short closed section: west a few miles to Unicoi, southwest to Erwin, Tennessee. It was the wee hours as I stopped in town, rolling down windows for fresh air. The place was dead, nothing moving but fast traffic nearby - Interstate 26. So late and tired, I needed a pullover spot soon. I came upon idling 18-wheelers outside town, but checking the map, I spotted a rest stop miles south. Pulling in, only one other car was there - perfect for quiet rest with another long day ahead. Waking in the morning, stepping out to stretch, I met a smiling girl in her early 20s, also full-time traveling in that car. I don’t recall her name, but I’ll call her Jabber-Jaw, that girl could talk endlessly. She said she awoke when I arrived, relieved after feeling scared alone in the lot. We chatted; I encouraged her to continue adventuring, find a husband, start a family.

Not all overland miles are gravel and stone; along the SEBDR, occasional smooth two-lane pavement felt less like compromise and more like a gift. These roads swept through rolling countryside and mountain communities, revealing barns, valleys, and ridgelines rougher tracks hide. Far from diminishing, these sections affirmed overlanding is about the journey as much as the surface. As counterbalance to punishing rock and ruts, they added rhythm and variety - likely no more than 10 to 15 percent of my southbound miles so far, a modest contrast in a demanding route.

I noticed a pattern: on average, below half a mile elevation (2,640 feet), no real snow or ice concerns. North faces always had more than south, so dirt and gravel might carry higher on south sides, while north encountered it lower. Depending on face perpendicularity, differences exaggerated. Some call this relating to nature; I see it as common sense we all have but rarely use. A key travel insight: groups bring radio chatter, vehicle spacing, stop coordination for food or camp - cluttering an immersive journey. I’m not negative on groups, but reinforcing our instinct to travel alone, immersing in the natural world.

Traveling over Bald Mountain north of Hot Springs, NC, felt like ascending into another season. The Forest Service road climbed the north face, hard-packed and ice-glazed, demanding patience with each turn. Towering rhododendrons closed in, forming a glossy green tunnel unreal against frozen brown earth. The contrast struck - vivid life in winter’s dead, ancient shrubs defiant amid ice, shadow, cold. Air hushed and heavy, tires spinning softly upward, it felt like passing through hidden sacred space, a corridor where winter loosened grip enough for green to endure.

At its core, "The Winners" reflects Kipling’s belief that progress and strength forge in solitude, not crowds. The line “He travels the fastest who travels alone” echoed as I rested by a creek, tracing gnarled roots gripping earth. That mirrored my path - years of solitary work, including jumps from helicopters into dark ocean, aircraft fading so I worked undisturbed. Kipling’s poem isn’t lonely; it’s resolute, arguing we must learn aloneness without diminishment, act decisively sans reassurance, stand firm when noise fades and responsibility remains.

I found myself beside Paint Creek again, picking across rough slick stones, cold seeping through boots as I paused to absorb it. Across a wide, slow bend of partially frozen water, a waterfall whispered and thundered, forty feet away yet another world. Air crisp and clean, pine-scented, softened by canopy light, grounded by stone’s bite. The sound - steady, alive, magnificent - no recording captures without losing soul. Sitting there, I wished to hand it to you like warm coffee on cold morning. Instead: this weekend, explore. Even briefly, map a forest, park, wildlife area - federal, state, local. Your current vehicle is right. Join birds, fish, quiet woods watchers; immerse in the world our Father created for enjoyment. Happy trails.