You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another Gen1 Tundra Thread

- Thread starter AaronK

- Start date

toyotech

Expedition Leader

I have the same pack. Maybe I just carry more weight than normal but it couldn't hold up much weight let along tow with out sagging. The 3 leaf was never meant for load capacity and I knew this going in. I just didn't want their single aal for load knowing it probably be too stiff.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

AaronK

Explorer

I only carry 300-400 lbs of gear for any given trip. With just the factory springs being so soft, that amount of weight would drop the bed so far I had less than 2" bump travel.

Now I have about 4" unladen and the spring rate has definitely increased. We'll see. Just hard to justify $800 for a whole new pack

Sent from my OnePlus One using Tapatalk.

Now I have about 4" unladen and the spring rate has definitely increased. We'll see. Just hard to justify $800 for a whole new pack

Sent from my OnePlus One using Tapatalk.

toyotech

Expedition Leader

I only carry 300-400 lbs of gear for any given trip. With just the factory springs being so soft, that amount of weight would drop the bed so far I had less than 2" bump travel.

Now I have about 4" unladen and the spring rate has definitely increased. We'll see. Just hard to justify $800 for a whole new pack

Sent from my OnePlus One using Tapatalk.

Oh I agree it hard to drop so much for springs. That's why I did the AAL as well. What Stop me from going a new pack was it would have to be custom and I doubt anyone could do one without having to have my truck for prototyping.

Sent from my iPhone using Tapatalk

theBullfrog125

Adventurer

The best way to add a slight amount of height and some extra load carrying capacity would be to have a leaf installed between the main leaf and second leaf. That length of spring wouldn't affect the ride quality as much as a shorter add a leaf does, because there is more leverage.

Leaf springs are a PITA to tune. I've torn into my Chevy packs 5 times now. I finally have it where I want it but it's been a long process.

Leaf springs are a PITA to tune. I've torn into my Chevy packs 5 times now. I finally have it where I want it but it's been a long process.

theBullfrog125

Adventurer

I'd be happy to share what I've learned if you end up going with 63s. I like the ride dynamics now that I've gotten the spring rate and shackle angle where I want it.

smokeysevin

Re-redoing things the third time

Deaver will do a custom pack without having the truck, they have the g57 or c27 they use as a base.Oh I agree it hard to drop so much for springs. That's why I did the AAL as well. What Stop me from going a new pack was it would have to be custom and I doubt anyone could do one without having to have my truck for prototyping.

Sent from my iPhone using Tapatalk

Sean

toyotech

Expedition Leader

Deaver will do a custom pack without having the truck, they have the g57 or c27 they use as a base.

Sean

Every tundra owner that did a custom pack ended up less satisfied. It doesn't matter now. I'll see first hand soon.

Sent from my iPad using Tapatalk

AaronK

Explorer

Been slacking on updating this. Lots of updates have happened during the second half of 2016 and I've been too busy and/or lazy to post them up here.

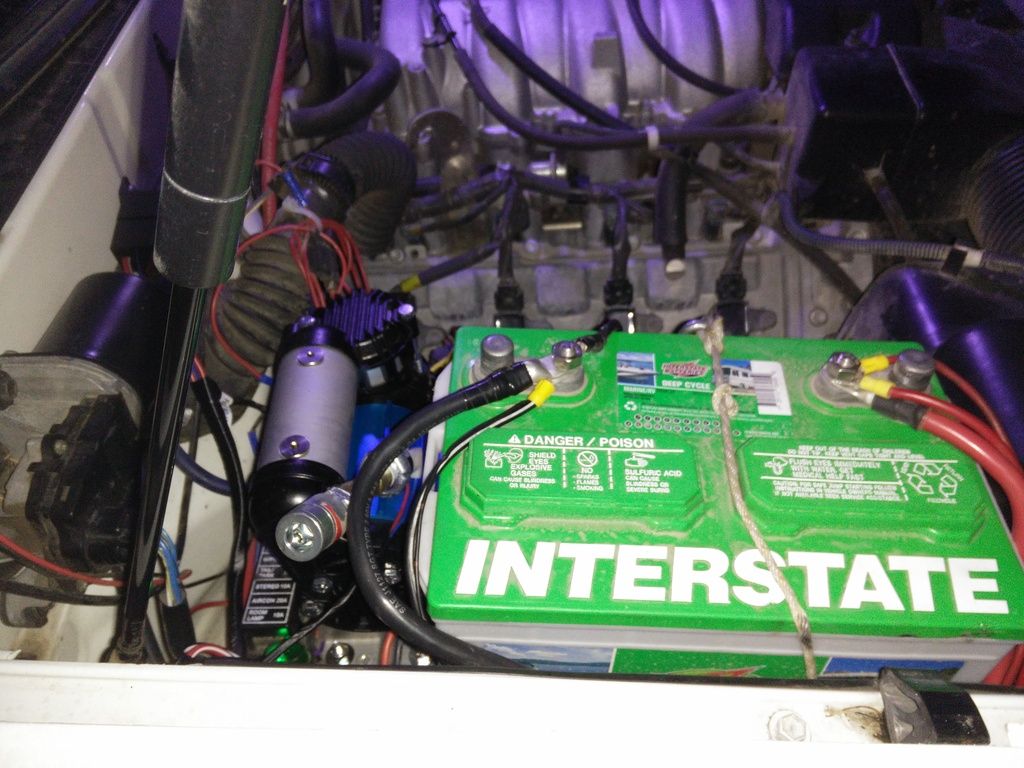

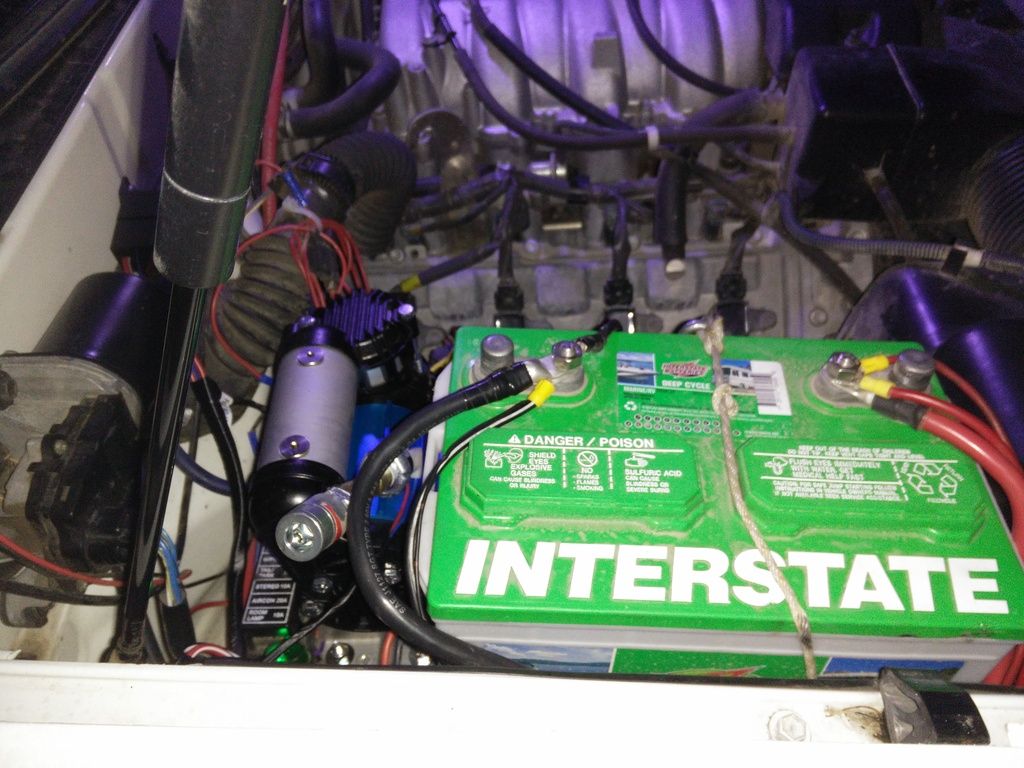

One of the bigger things that happened this year was the addition of a 40L Ironman fridge. This put a much larger strain on my electrical system than I had been used to. Initially, I planned on just doing a single battery of a much larger size. I like the simplicity of one big battery. The fridge would cut itself off if the battery ran low. Huge savings in space and cost of implementing a dual system. Then funny thing happened on one of our trips. A door got left open on the truck for who knows how long. At least overnight. By the time we went to leave camp, there wasn't enough power to start the truck. This made me reevaluate my situation. I pulled the trigger on a dual system. Using a Group 24 flooded cell deep cycle from Interstate rated at 85Ah. Luckily, my truck doesn't have ABS so that frees up a LOT of space on the passenger fender for things. Ran 2AWG wire between the battery with a 150A circuit breaker. I opted for a Wirthco intelligent dual battery controller.

I was initially leaning towards a BlueSea model, but this one has a manual link option for jump starting and the Blue Sea one did not.

My awesome wife bought be an ARB on board air compressor. Up until this point, I've been using a 120v 3gallon compressor from Harbor Freight with an inverter because I already had it. It worked...slowly. Alas, it isn't rated for the duty cycle required to fill up 4 32" tires and started making some fun noises and smells. Every trip I expected it to fail. Then this showed up.

I fabricated some aluminum brackets and mounted it on the now crowded passenger fender between my house battery and fuse block

I'm much happier now knowing that I have a reliable compressor that's with me at all times.

More recently, a buddy offered me his Engo E9000 at a great price because he's getting ready to upgrade. I jumped on it because a winch was the next bigger purchase I was planning on making.

Unfortunately, there wasn't room between my light bar and grill to mount the solenoid box. I'm not really a big fan of how many people relocate them up into their engine compartments. Electrically, the shorter the wire run the better; especially at high amperage like a winch will draw. So I mounted the solenoid box to the top of the winch inside the bumper (it's basically a cavern inside an ARB bumper) and relocated the controller plug instead.

The ARB comes with a plate that covers up the holes on the top of the bumper where a winch goes. The idea is that you remove it if you are running a winch. I ended up just cutting it down so I could access the clutch lever. This left me with plenty of real estate to mount the controller plug and keeps the rope covered and out of the elements a little better.

I added a waterproof connector on the solenoid box where the original controller connector went so I can still easily remove everything if need be.

Here it is all put together.

Next I had to get a fairlead. Being a synthetic rope, most people would use a Hawse fairlead. While I know thousands of people use these without issue, the idea of the friction of sliding a winch line across a non-moving part just didn’t sit right with me. I ended up getting a roller fairlead with urethane rollers made by Daystar.

I’ve had the opportunity to use the winch a few times now (seriously people, a Subaru Outback is not a snow wheeler!) and the Daystar rollers seem to be performing flawlessly.

One of the bigger things that happened this year was the addition of a 40L Ironman fridge. This put a much larger strain on my electrical system than I had been used to. Initially, I planned on just doing a single battery of a much larger size. I like the simplicity of one big battery. The fridge would cut itself off if the battery ran low. Huge savings in space and cost of implementing a dual system. Then funny thing happened on one of our trips. A door got left open on the truck for who knows how long. At least overnight. By the time we went to leave camp, there wasn't enough power to start the truck. This made me reevaluate my situation. I pulled the trigger on a dual system. Using a Group 24 flooded cell deep cycle from Interstate rated at 85Ah. Luckily, my truck doesn't have ABS so that frees up a LOT of space on the passenger fender for things. Ran 2AWG wire between the battery with a 150A circuit breaker. I opted for a Wirthco intelligent dual battery controller.

I was initially leaning towards a BlueSea model, but this one has a manual link option for jump starting and the Blue Sea one did not.

My awesome wife bought be an ARB on board air compressor. Up until this point, I've been using a 120v 3gallon compressor from Harbor Freight with an inverter because I already had it. It worked...slowly. Alas, it isn't rated for the duty cycle required to fill up 4 32" tires and started making some fun noises and smells. Every trip I expected it to fail. Then this showed up.

I fabricated some aluminum brackets and mounted it on the now crowded passenger fender between my house battery and fuse block

I'm much happier now knowing that I have a reliable compressor that's with me at all times.

More recently, a buddy offered me his Engo E9000 at a great price because he's getting ready to upgrade. I jumped on it because a winch was the next bigger purchase I was planning on making.

Unfortunately, there wasn't room between my light bar and grill to mount the solenoid box. I'm not really a big fan of how many people relocate them up into their engine compartments. Electrically, the shorter the wire run the better; especially at high amperage like a winch will draw. So I mounted the solenoid box to the top of the winch inside the bumper (it's basically a cavern inside an ARB bumper) and relocated the controller plug instead.

The ARB comes with a plate that covers up the holes on the top of the bumper where a winch goes. The idea is that you remove it if you are running a winch. I ended up just cutting it down so I could access the clutch lever. This left me with plenty of real estate to mount the controller plug and keeps the rope covered and out of the elements a little better.

I added a waterproof connector on the solenoid box where the original controller connector went so I can still easily remove everything if need be.

Here it is all put together.

Next I had to get a fairlead. Being a synthetic rope, most people would use a Hawse fairlead. While I know thousands of people use these without issue, the idea of the friction of sliding a winch line across a non-moving part just didn’t sit right with me. I ended up getting a roller fairlead with urethane rollers made by Daystar.

I’ve had the opportunity to use the winch a few times now (seriously people, a Subaru Outback is not a snow wheeler!) and the Daystar rollers seem to be performing flawlessly.

wrenchMonkey_

Adventurer

Blue Sea makes the ML-ACR with the remote switch, the same one I used, which has a PN of 7622. They make various versions with the manual on top of the unit and the remote in cab switch.

Nice score on the ARB compressor, I need some OBA.

Great mod on the winch and bumper.

If you have a minute, how much clearance do you have from the bottom of your bumper to the floor? Just looking for you ground clearance.

Trucks looking great!

Nice score on the ARB compressor, I need some OBA.

Great mod on the winch and bumper.

If you have a minute, how much clearance do you have from the bottom of your bumper to the floor? Just looking for you ground clearance.

Trucks looking great!

toyotech

Expedition Leader

Too bad the single big battery didn't work for you. I'm still running a big single battery and have a fridge as well. I also have a solar panel hard mounted so if the battery did die. Within an hour of sun. It would be charged back up if needed. I also carry a small jump pack as a back up.

Sent from my iPad using Tapatalk

Sent from my iPad using Tapatalk

AaronK

Explorer

What is "sun"? HahaToo bad the single big battery didn't work for you. I'm still running a big single battery and have a fridge as well. I also have a solar panel hard mounted so if the battery did die. Within an hour of sun. It would be charged back up if needed. I also carry a small jump pack as a back up.

Sent from my iPad using Tapatalk

In hindsight I think I'd rather go the single route.

I thought it'd be cheaper going dual since I already had a battery. Then I paid $3/foot for wire (20 feet), 8 ring terminals at $2 ea, $30 or so for the circuit breaker. Then the $15 solenoid didn't work out how I wanted so I spent $70 on the Wirthco.

It quickly added up to the price of a big single battery.

Live and learn...

Sent from my OnePlus One using Tapatalk.

Similar threads

- Replies

- 67

- Views

- 6K

- Replies

- 2

- Views

- 1K

- Replies

- 7

- Views

- 2K

- Replies

- 17

- Views

- 2K

- Replies

- 0

- Views

- 497