In this next series of posts I'll describe the charging system I've been using for the last 4 years as part of my MORryde Trail Kitchen installation. I'll also cover a bit about how I provide power to the kitchen accessories, what type of kitchen battery I use, and a little bit about adding solar charging to the system.

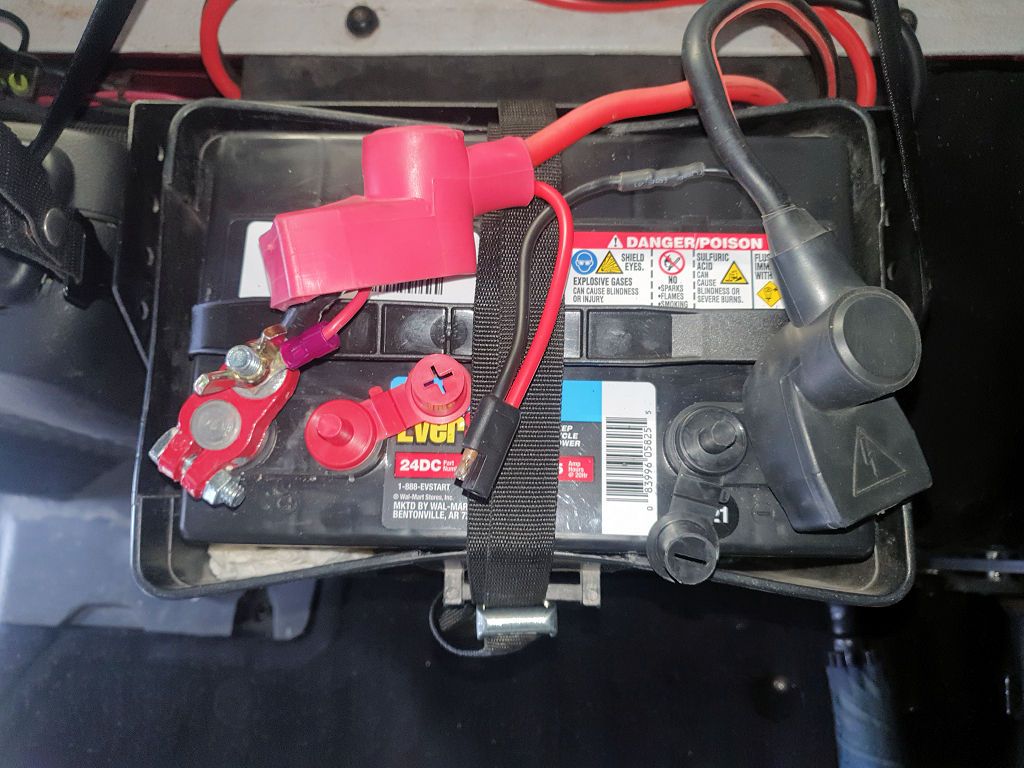

When I first got a refrigerator, I powered it simply by using the power outlet in the back of the Jeep, but I wanted to have a dedicated battery for the fridge so the fridge could run without worry when the Jeep was parked in the wild. I looked at the dual battery systems on the market but they were expensive, many require engine compartment changes and some require expensive AGM batteries because in those the two batteries have to go in on their side to fit in the engine compartment.

Some of the systems on the market are pretty sophisticated, with electronics to ensure that the main battery gets fully charged before the auxiliary battery, automatic switching of the aux battery into the starting circuit when the main battery is low, automatic use of the main battery to supplement the aux battery when the aux battery is low, automatic cutoff of loads on either battery when a that battery gets low, and more.

Those systems work well, but if the aux battery is primarily used for the kitchen and not needed to be part of a true dual battery system, something simpler and less expensive will do the job, so that's what I decided to design and implement.

These were my initial design requirements:

- Keep the kitchen/fridge battery charged (obviously the most important requirement).

- Don't ever drain the main battery because of the kitchen.

- Simple and cost-effective to implement - I use the kitchen in both my JKU and my LJ, so I need to implement whatever solution I chose in two Jeeps.

- Easily adaptable to any Jeep (or other vehicle a fridge might be installed in).

- Easily adaptable to solar charging of the kitchen battery.

- Simple enough so that if some component fails while on an expedition, replacement components should be easily available at the nearest point of civilization.

- Should be possible to use the kitchen battery to start the Jeep in an emergency.

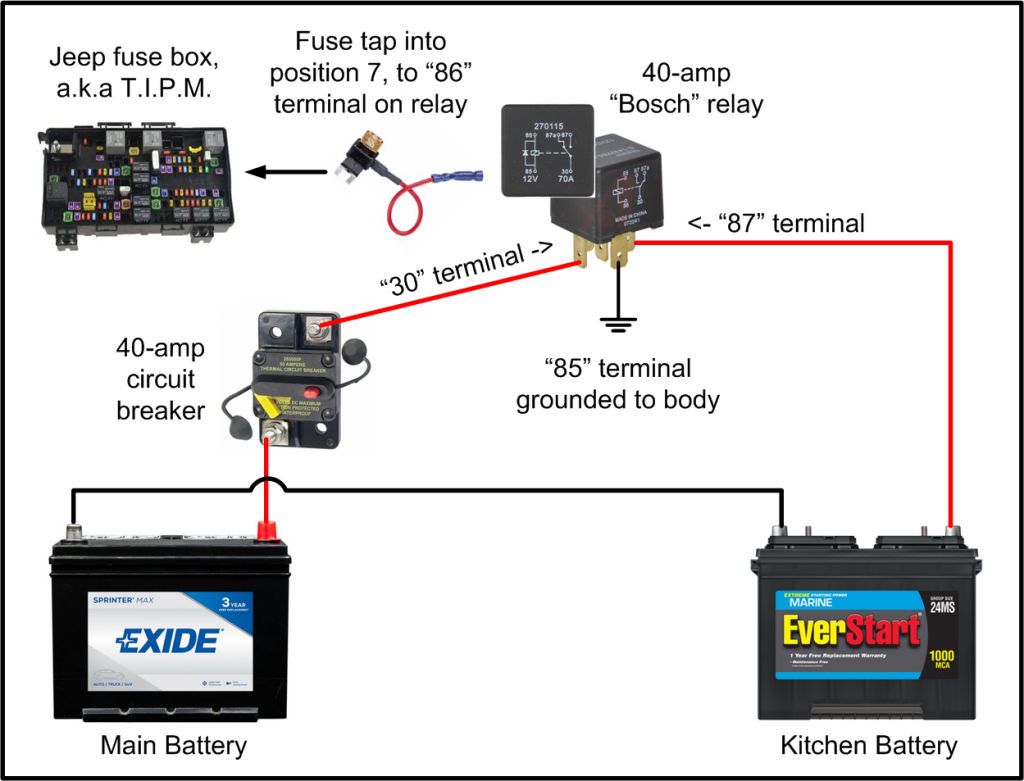

The design I came up with meets all those requirements, is very simple and has been working great for more than 4 years now - it connects the kitchen battery in parallel with main battery so the alternator charges both the main battery and the kitchen battery. To prevent the kitchen from discharging the main battery, the kitchen battery/load is disconnected from the main battery when the Jeep isn't running and connected for charging when the Jeep is running.

A simple relay is all that's needed to make/break the charging connection, and the most important design details are about the current requirements for charging the kitchen battery and minimizing voltage losses and cost.

A pictorial schematic (each section and components will be explained in this and following posts):

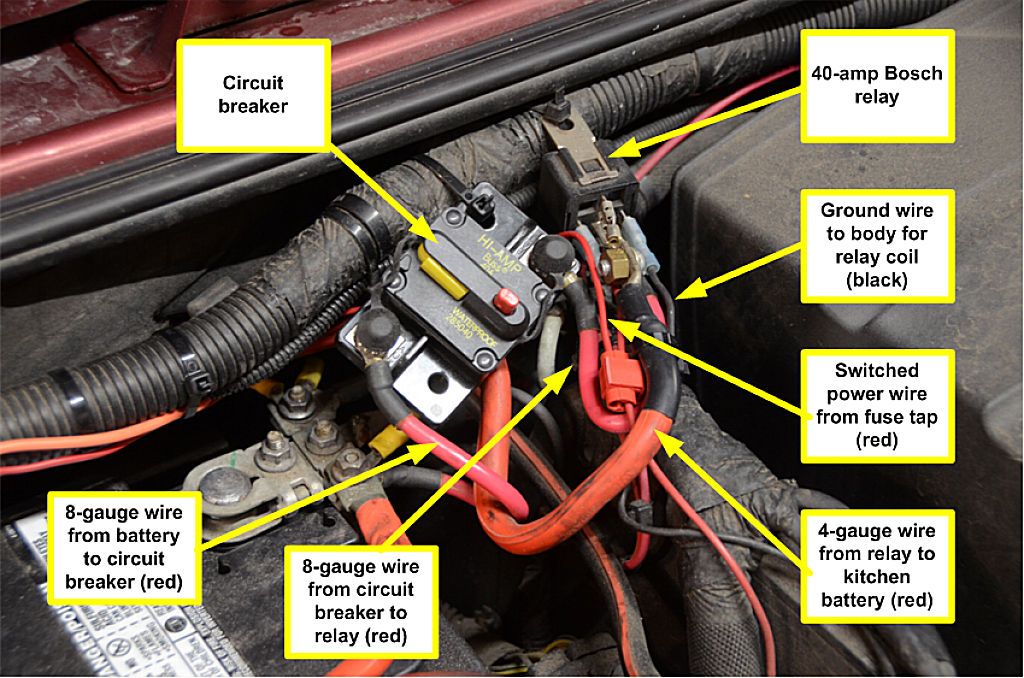

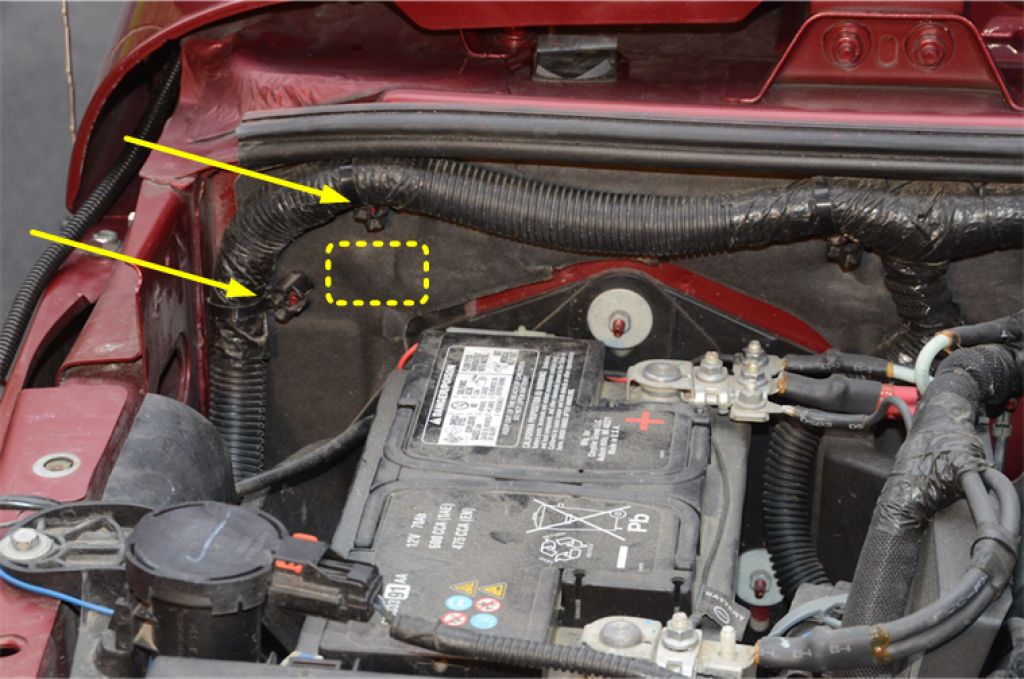

In the engine compartment there's a 40-amp relay to do the switching. I did extensive testing with the fridge battery in all states of charge and even a very discharged battery never drew more than about 34 amps, so a 40-amp relay is sufficient. I used an ordinary Bosch automotive relay because it meets requirements 3 and 6 - Bosch relays are available at every auto parts store and relatively inexpensive. If you're not comfortable using a Bosch relay for whatever reason, higher capacity relays/solenoids are available. Pictured below is a Bosch relay (40 amps, left) and a 500-amp relay.

One reason to use a much higher capacity relay is for starting the Jeep with the kitchen battery - the starter motor requires more current than a tyical Bosch relay can handle, but more on that later in this discussion - I'll explain why I used a Bosch relay in spite of that.

Adequate protection for the circuit is required - the alternator is capable of providing a lot of current so if something goes wrong or a short develops either a fuse or a circuit breaker is required to protect the alternator/main battery. Initially I used a 40-amp ATO/ATC-style fuse because of requirements 3 and 6, but after using the system a while a "nice to have" requirement came up - being able to switch the system off. Since I swap my kitchen and its battery between Jeeps, I need to switch off the power to the kitchen when it's in the other Jeep. I got tired of pulling the fuse so I installed a circuit breaker. But a fuse is all that's needed and it better meets requirement 6 than a circuit breaker does.

A 40-amp fuse in a fuse holder is more than adequate for the job, but what I like about the circuit breakers pictured above is that they have a switch so power can be turned off. If I remove the battery for some reason, I can turn the circuit off so no power is in the circuit when the battery is removed, eliminating the possibility of a short circuit with the loose battery connectors. But that's a convenience, not a necessity, so a fuse holder will do fine and you can pull the fuse if you need to cut off power.

In both Jeeps I originally used Scorpion brand breakers in the photo above, but two of them failed in the JKU. On one the switch mechanism broke and the other keep popping below its rating in very warm weather. I spent a little more money and switched the JKU to the Buss fuse at right and I plan to replace the Scorpion breaker in the LJ with a Buss breaker as well but haven't gotten around to that yet because I don't use the kitchen in the LJ as often as I do in the JKU.

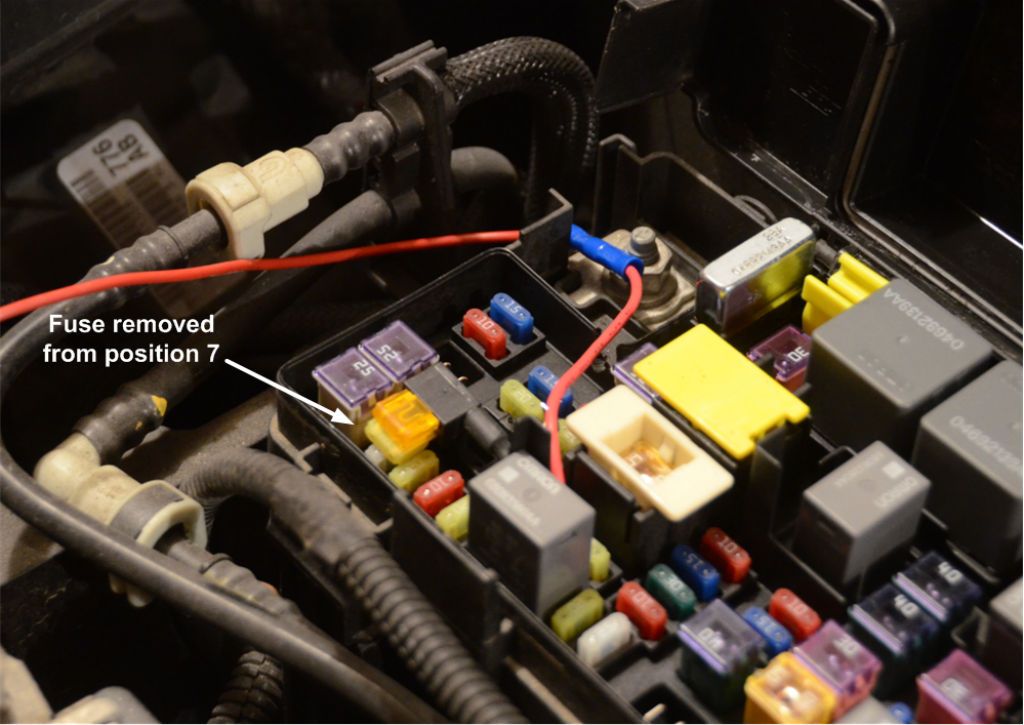

The only other thing in the engine compartment is a connection to switched power to control the relay, which I did with a fuse tap. On the JK, I replaced fuse #7 with the tap. If you're not familiar with fuse taps, they generally have two fuses/two circuits - one fuse replaces the fuse that was removed from the position the fuse tap is installed into and the other fuse is for the additional circuit (in this case, the new relay).