Back to making brackets for a little bit....

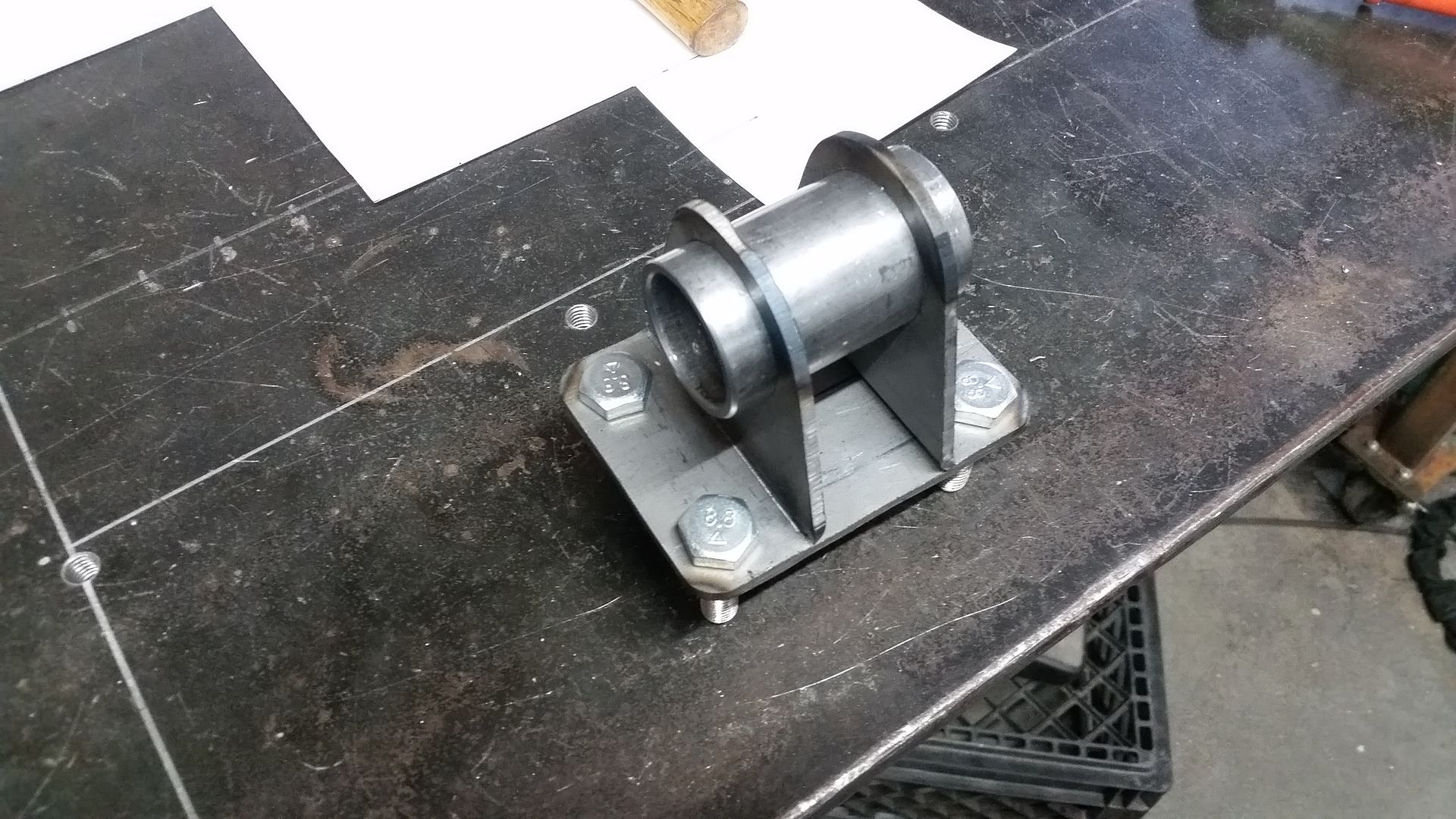

This is the C-pillar 5th body mount that will be on the upright that splits the rear window. It is the same size bushing as all the other body mounts so they can share a common part. This body mount will tie into some of the structure that will be the base of the bed ( which also will be providing the fuel tank mount, mount for the bed tube work, battery mount, light mounts, some bumper structure, and a few things I am probably forgetting ).

Yes, The floor plate is going to have counter sunk hardware. I need the extra clearance in the corner for the modular hard top rear window storage plan. I will likely be welding those fasteners into the bracket to help prevent pull through.

I was even a good boy and tig'd them. I need the practice. I should probably box them in in tonight, but I don't need to do that right now. I just needed to design the floor plate really, but I wanted to weld up the actual mount when bolted to the actual plate so I know it would all fit together.

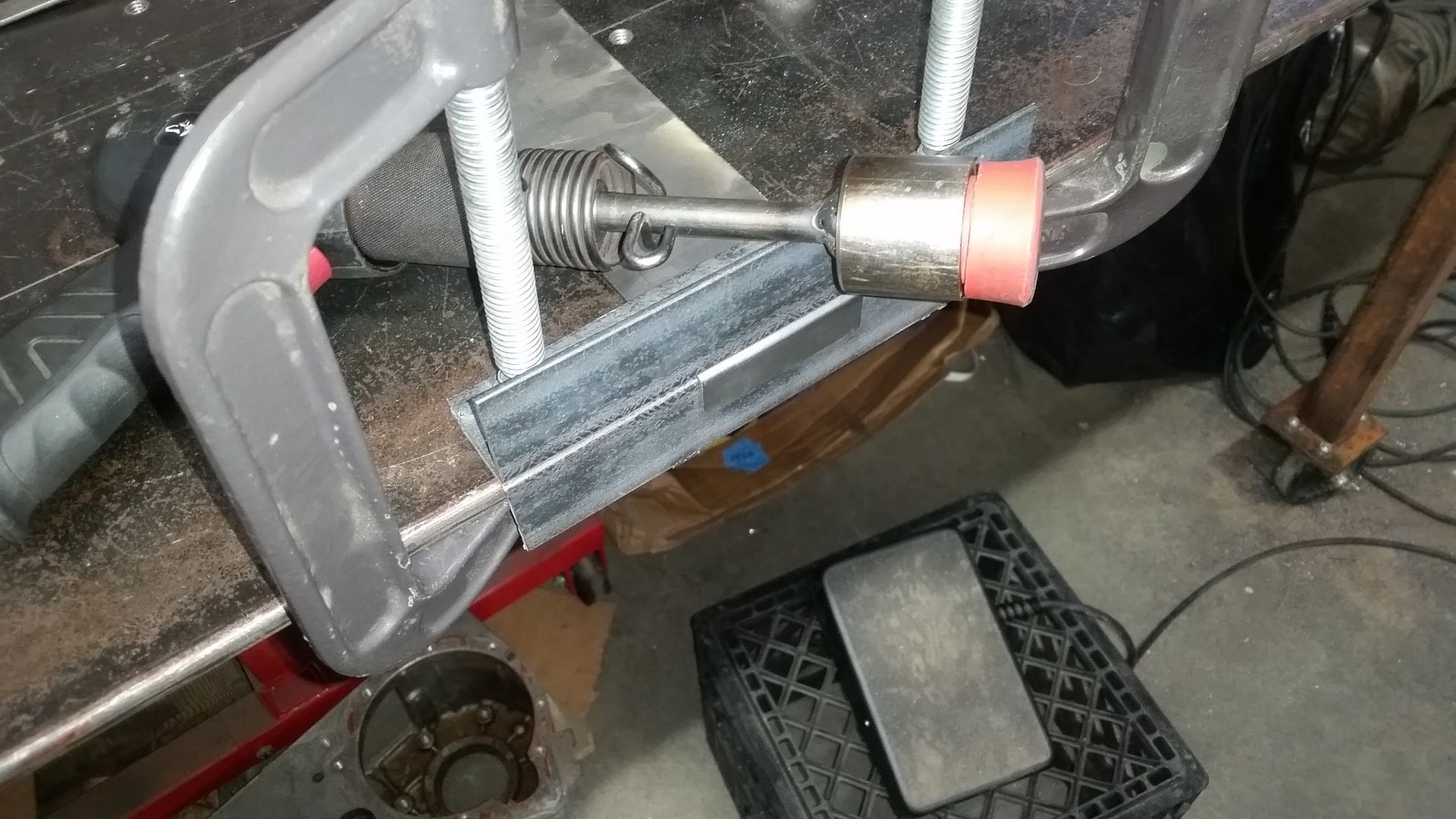

Mocking it up all bracket to bracket lets me make sure it will fit after I pull it apart.

Fab tip of the day. Drill all your holes before the brackets have been cut apart if you can. It sure makes it easier to hold smaller parts. I have a love/hate relationship with those Blair Holcutters. They cut a GREAT hole compared to a hole saw, but I will no longer use them with a hand drill. They are too grabby, aggressive, and fragile for that in my opinion. I am cutting 10 gauge which is at the upper limit. Perhaps on something thinner they would be better with a hand drill.