Removable, always removable. You work a lot by yourself, having a removable tunnel so you can have top and bottom access to your trans and t-case is much more convenient for linkage and component installation and adjustments. Plus you can hang straps and come alongs to your roll bar to help install and remove said parts.

I used to lay a pipe across the window sills and use a come along to drop the SM420 out of my 63 Chevy 4x4 to replace the clutch. I was thankful for that removable floor tunnel.

On your cab ribbing are you limited by the throat or depth of your tools? Most truck cab ribs seem to be a few inches above the bottom cab seam and extend maybe a third of the way up the back of the cab. They don't come very close to the window level at all. Your surface area compared to the back of a full size pickup cab is much smaller and if your metal is thicker than standard cab stampings you may be able to get by without any strengthing ribs.

On the tunnel....

I hear where you are coming from....but ugh. When you start looking at all the details envolved in trying to implement that it starts to look like not such a good idea....

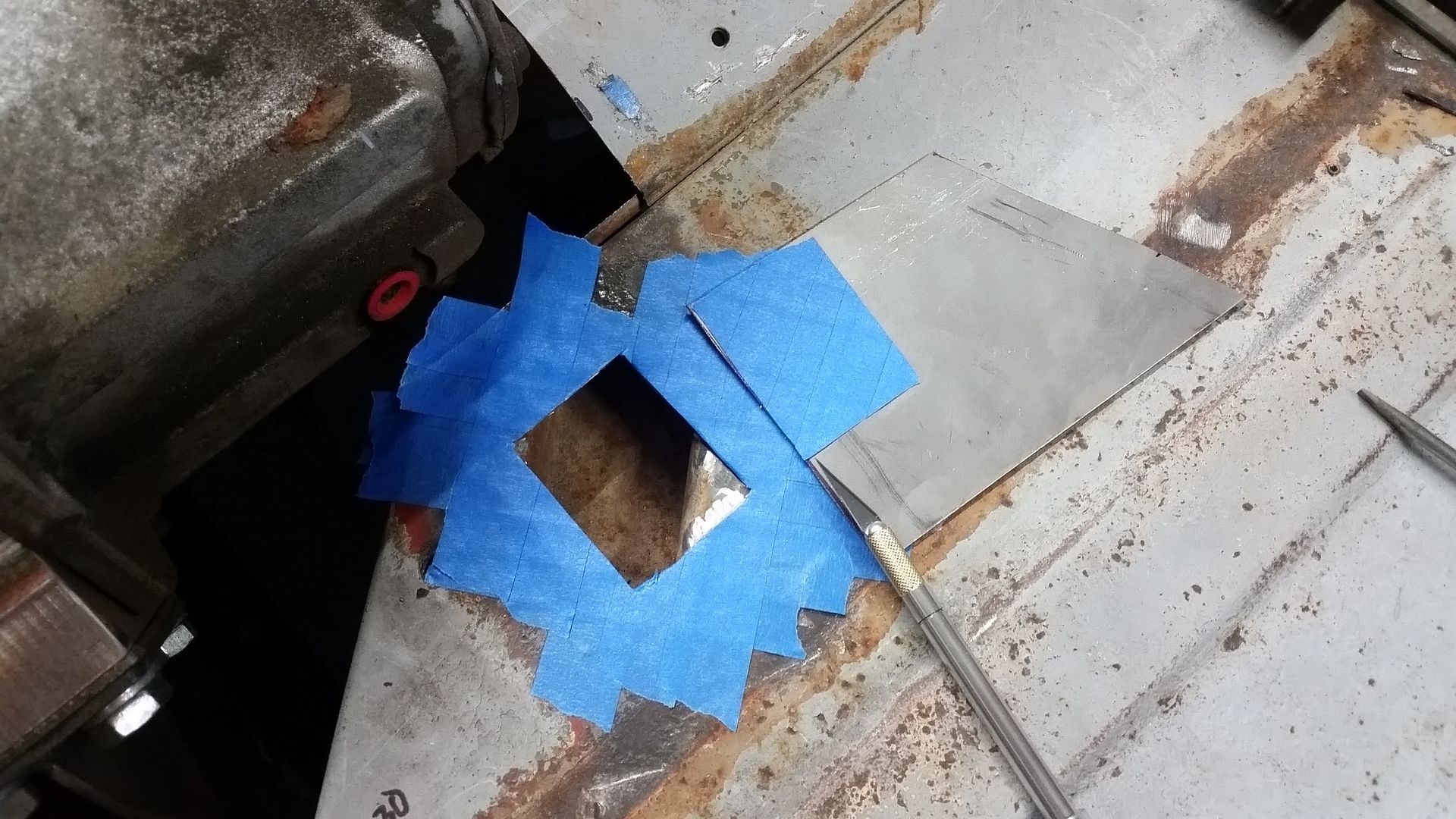

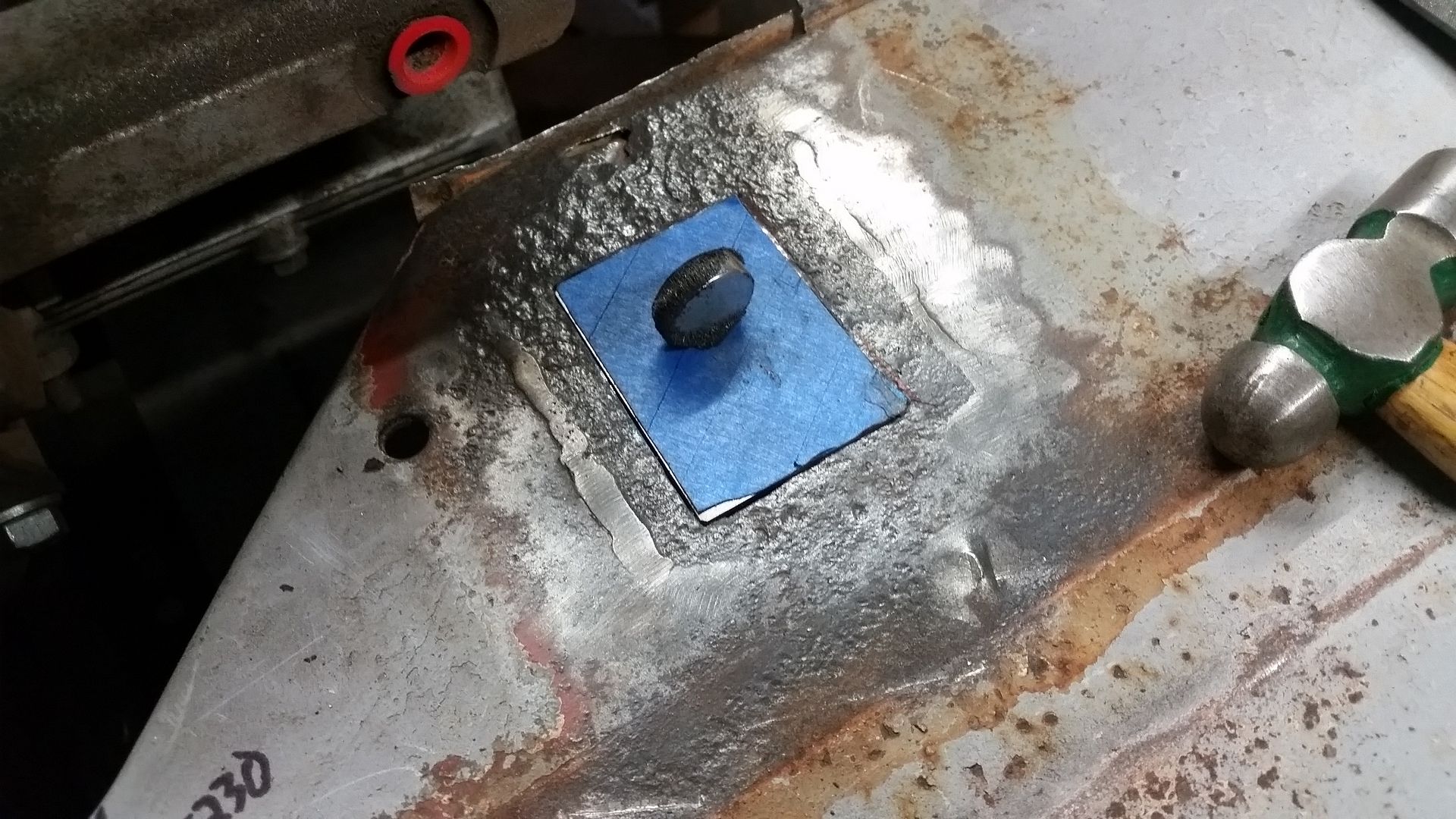

This is where I am at basically.

Good things about a removable tunnel....

-You can get at stuff

Issues I see....

-It doesn't provide as much support in the floor. A welded structure will be stronger

-The inner seat mounts on this narrowed cab will likely be on top of the transfer case. Combining the seat mounts into/onto a removeable part doesn't give me a warm fuzzy feeling.

-Removing the tunnel, once the seats, shifters, and pedals are in place will not be an easy thing to do. It would likely require sub panels on a removable tunnel to be able to take everything apart.

-Removing the entire tunnel to get at a small issue seems like a lot of work. You could add sub panels but that is a lot of extra parts.

-Typically I find that captured hardware on the underside of the vehicle doesn't last long with dirt/mud. There are sealed back rivet-nuts now that are promising.

With the flat belly the transmission ended up pretty far up into the floor along with the transfer case.

I did design this cab with an interesting body mounting system. I can pull the 5th body mount bolt at the single C-pillar. Then remove two bolts on either side of the body and the entire cabin should pivot on the other body mounts. This can create a decent amount of additional under the floor space for access to things with minimal extra work. Pulling the entire tub shouldn't be too hard.

With the way this truck is built, the small cab size, and the fact that the trans/tcase are pretty far up into the body......I just don't see a clear path to a removable tunnel.

If anything, I think the tunnel almost needs to be removable AND have access panels to certain areas. That just sounds like a TON of work and complexity.

I do like the idea that I could create an all new flange for the tunnel and not have to weld to nasty old sheetmetal for multiple feet of welding.

I don't like the idea of the fasteners used to join the tunnel to the floor sticking up. I might have to look at some other options for that.....countersink or a flush fastener or ???

I don't really love captured nuts under the floor. They don't seem to hold up too well over time. Rivet nuts night work if the lineup can be close enough.

I think the gas pedal might have to mount near the tunnel....need to check that out a bit.

The seat mounts

Yuck. No 'fun'