Little bit more....

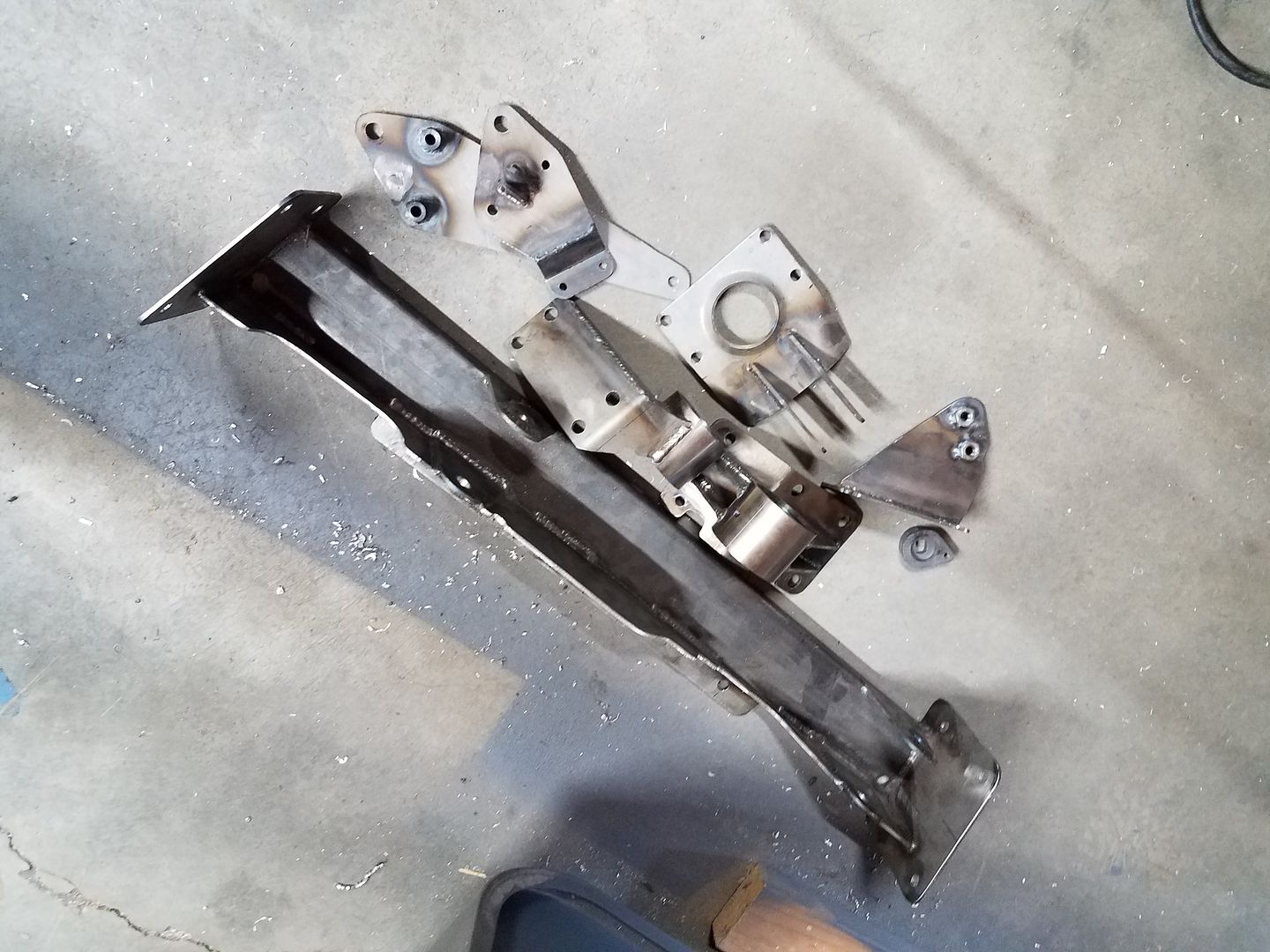

Somewhere in there I forgot to get the forward support for the belly pan powder coated. I dropped that off, got it back like 48 hours later, and then went ahead and installed it.

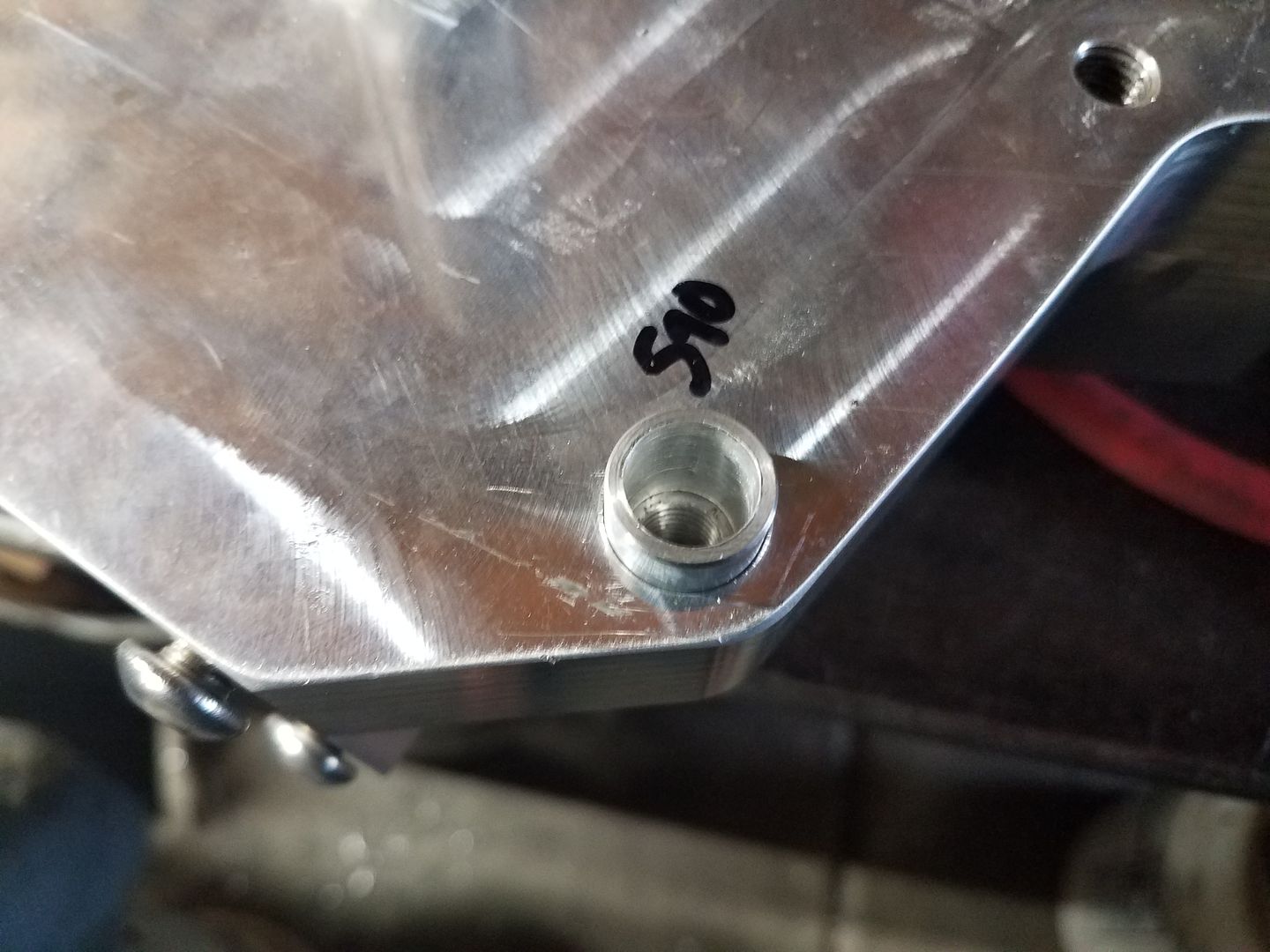

I am really liking these large clip nuts for the attachment of stuff like the belly pan where possible. They only take one tool, you can replace them, etc.

The grommets for the LED turn signals where designed for slightly thicker material than the grill shell. I ended up making a backing plate out of some old hole saw slugs which I welded to the grill. Now the grommet fits nice and tight.

I needed to make the hole in the middle larger to match the hole in the grill I had already done. The easy way seemed to be tacking the drops to a small scrap plate. Then using the same HolCutter and the existing center bit hole.

When I welded the backing plate into the grill I used a section of 3/4" round bar to locate the two bores concentric to each other for some tack welds.

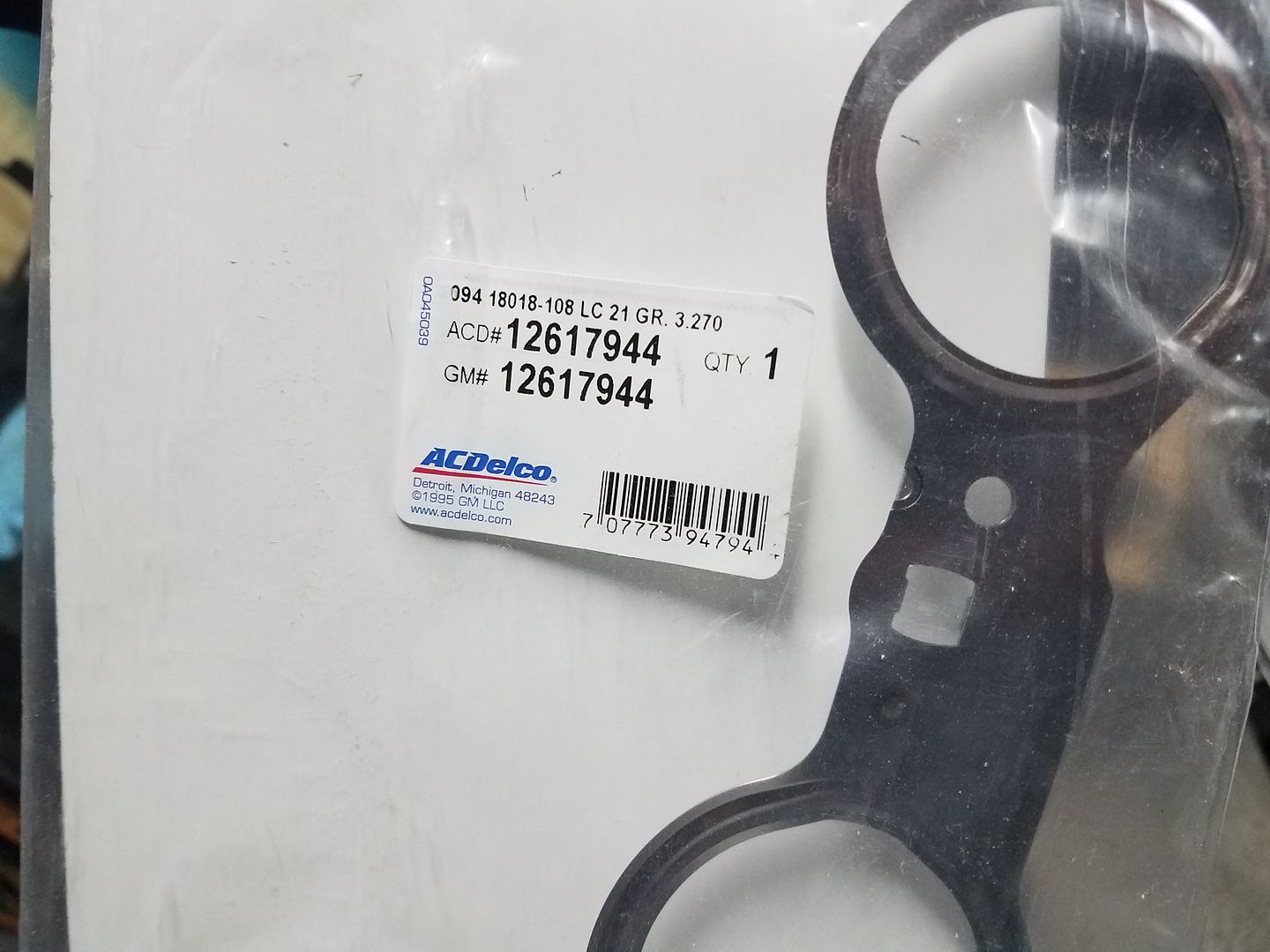

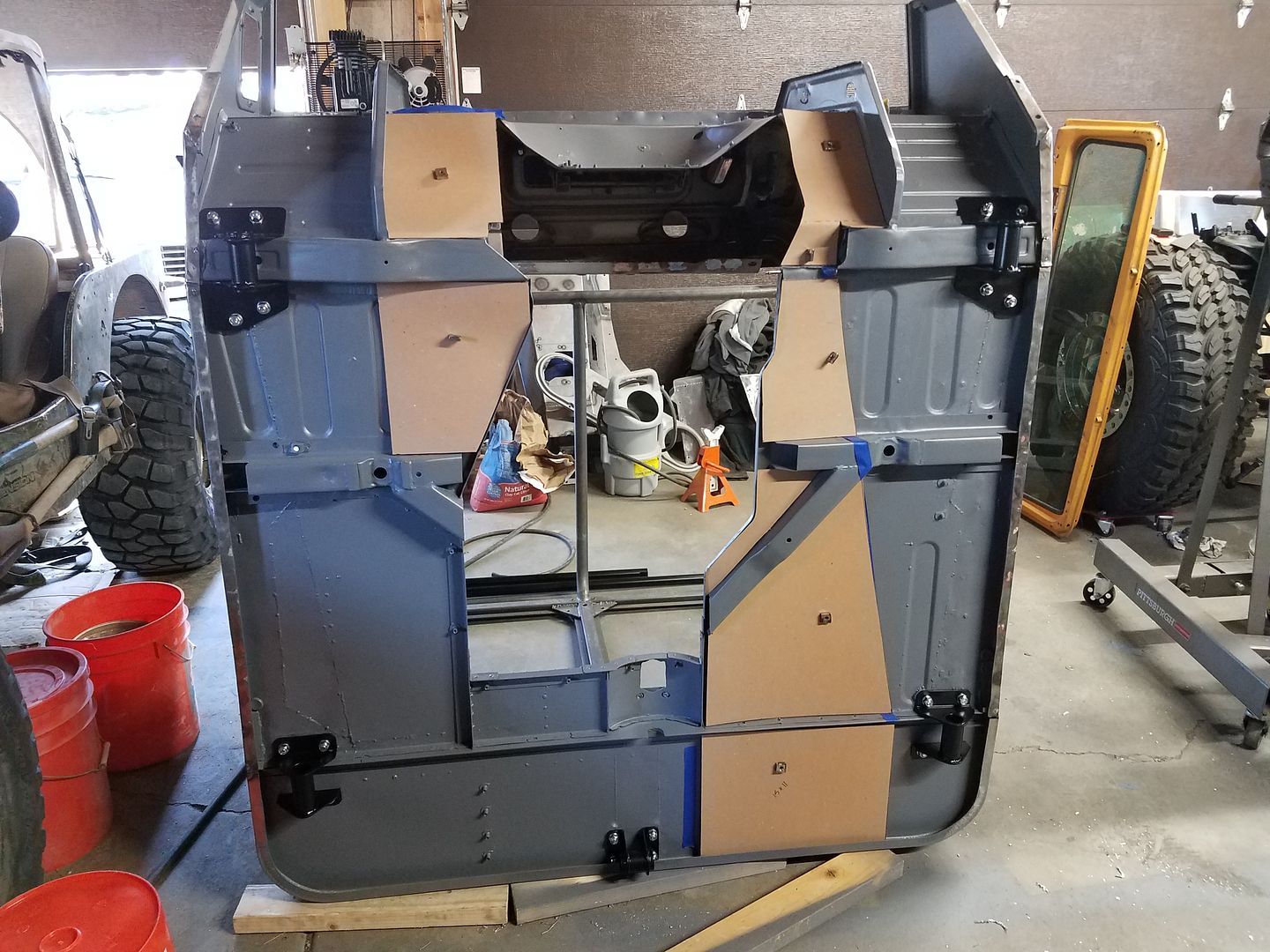

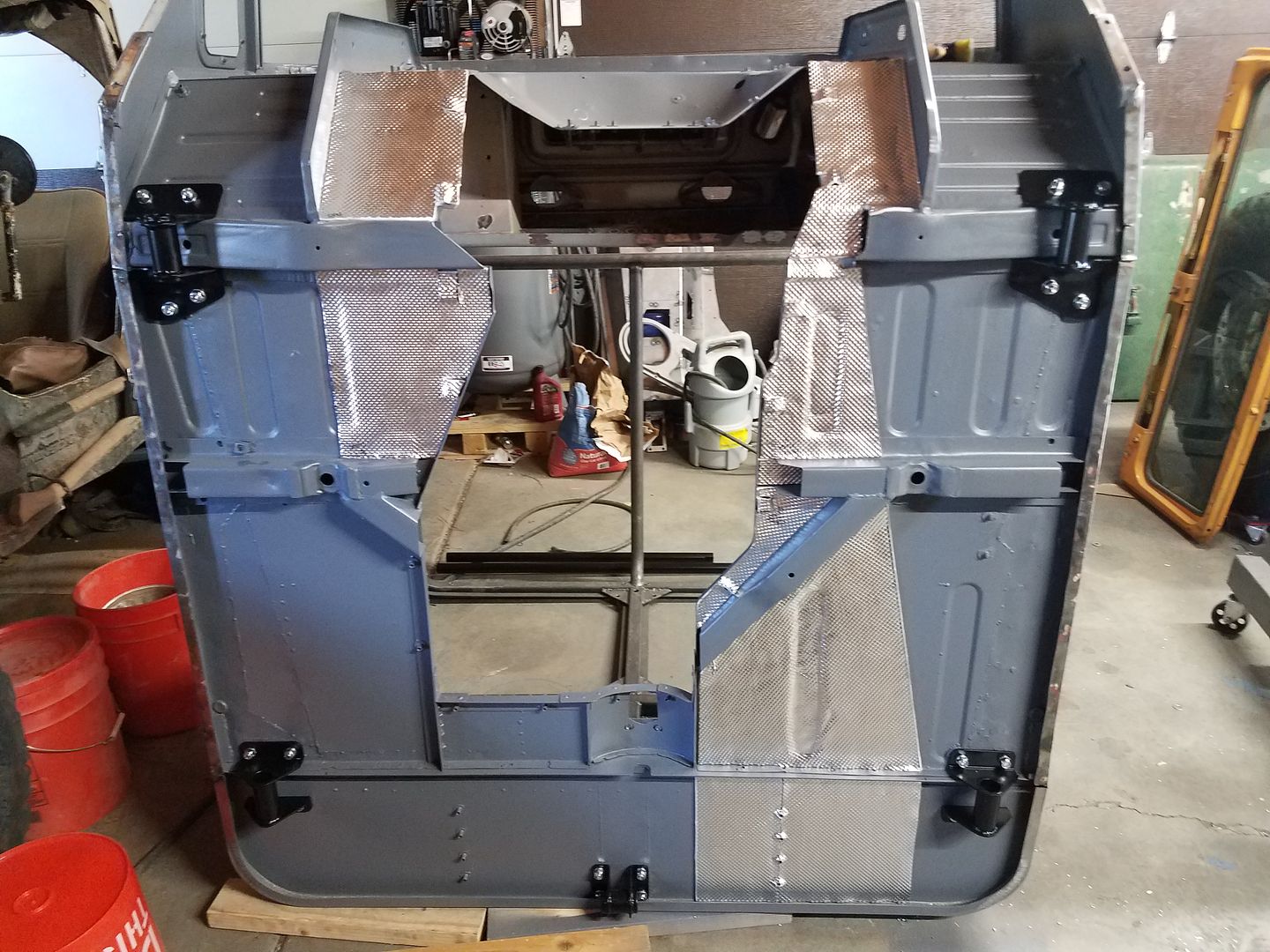

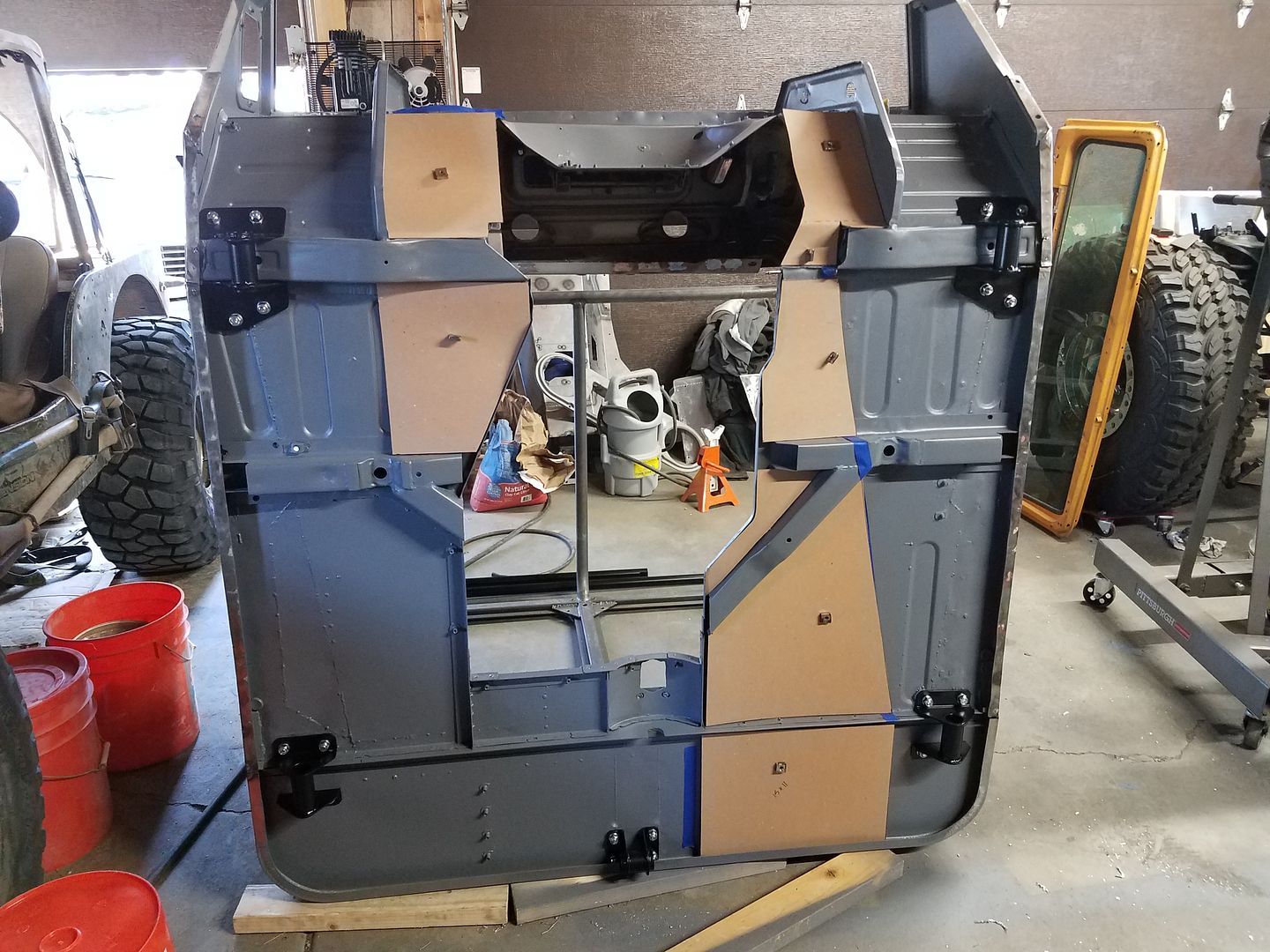

I also started prepping the tub to go back on the chassis a bit more. The coated body mounts went back on with proper length hardware and locking nuts. I also made pattern for all the DEI heat shield I will be adding to the tub. This helps me save material as I can nest the patterns on the raw sheet knowing exactly what I need.

I will also be coating the entire inside of the tunnel in the same DEI material later. It isn't super cheap, but it worked WONDERS on my flat fender with floor heat. This amount should be amazing for rejecting heat from the exhaust, transmission, and transfer case.

That catches me up for now.