jscherb

Expedition Leader

I've been thinking ahead to various options that might be interesting for these kits. I'd like to hear any input you have on these or any other options you'd like to see.

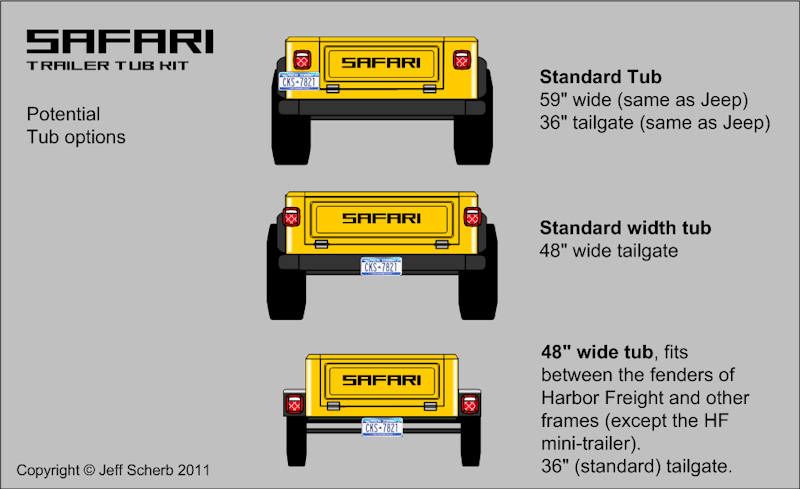

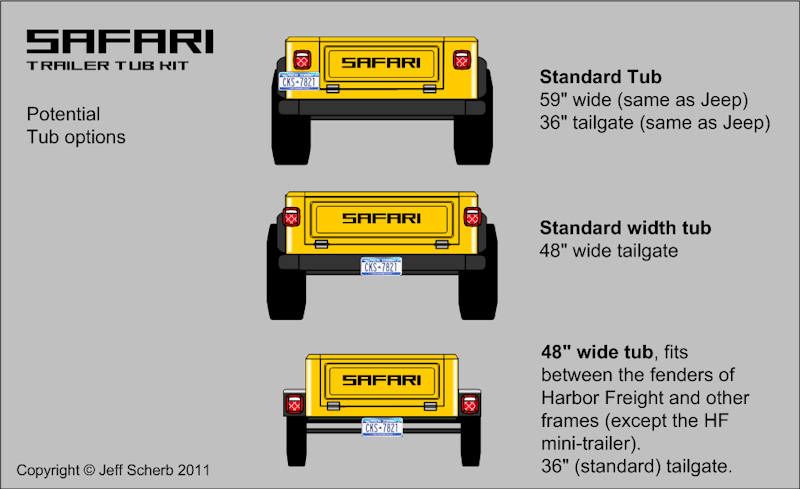

There are a few different tub/tailgate options that could be done:

The top tub in the drawing is the standard tub. The middle one is the standard width but has a 4' tailgate opening. The bottom one has 48" wide end panels (the standard end panels are about 59" wide), so it sits between the fenders of many trailers, including most of the Harbor Freight trailers, and the Lowes trailer I posted a while back. I've drawn it with the small HF tires; I think the narrow tub would look ok with the small tires that come with the HF frame.

A few other option ideas:

1. Stake pockets. Optional fiberglass molded parts that bond to the inside of the tub side. Stakes could be used to add higher sides to the tub made out of wood, or perhaps supports an "overhead frame" like some off-road trailers have.

2. Different width inner fenders, so people could choose the optimum axle track width for their application, and have inner fenders which didn't waste any space inside the tub by being too large for the track width chosen. Example, a standard Wrangler track width would require inner fenders to protrude about 9" into the tub from each side wall (resulting in abour 42" between the inner fenders; a wider track width could use 5 1/2" inner fenders allowing 49" between them. The mold master is already made for these, just have to make molds for different widths off that master. Or, tiny innner fenders could be done for people who plan to keep the original HF tires/wheels (would anyone keep those tiny tires?)

3, 4. (Never mind, edited these out and forgot to renumber)

5. Hard tonneau cover. For those who want the security of a locking hard cover, this also would be capable of supporting a roof rack and carry loads.

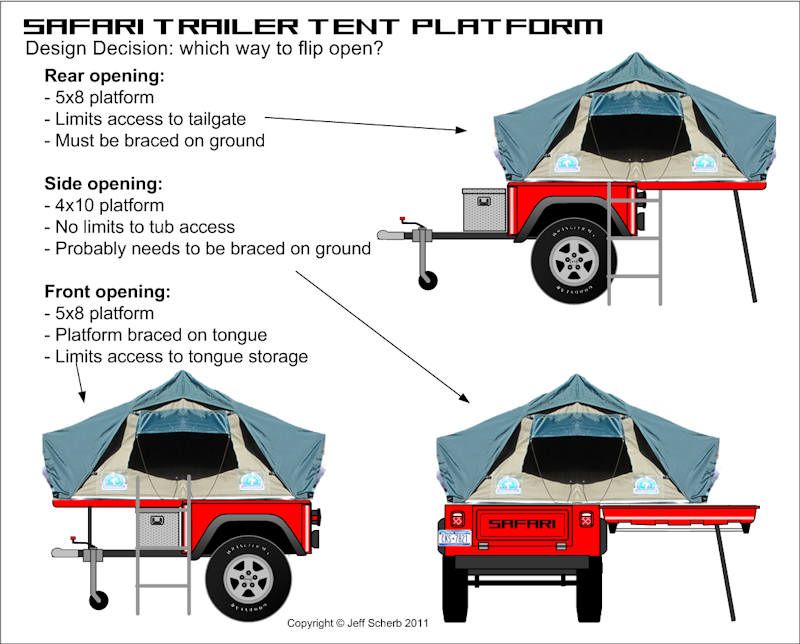

6. Tent platform. Derived from the hard tonneau, this would flip open, doubling the top area of the trailer, and serve as a platform for raising a tent. Inexpensive "ground tents" would be supported, so you could turn this into a tent trailer with this option and a $50 entry-level tent.

7. Side-swinging fiberglass tailgate. Probably for the guys who would put a tent on top of the trailer, a side-swing tailgate may allow easier access to the cargo area than a drop-down.

8. Nerf bars. I posted about them the other day.

9. The "lego" storage pod I posted yesterday.

Now that the base trailer is in the final details and finishing stage, it's time to start thinking about any other features/options I might build for it. Any other options you guys would want?

There are a few different tub/tailgate options that could be done:

The top tub in the drawing is the standard tub. The middle one is the standard width but has a 4' tailgate opening. The bottom one has 48" wide end panels (the standard end panels are about 59" wide), so it sits between the fenders of many trailers, including most of the Harbor Freight trailers, and the Lowes trailer I posted a while back. I've drawn it with the small HF tires; I think the narrow tub would look ok with the small tires that come with the HF frame.

A few other option ideas:

1. Stake pockets. Optional fiberglass molded parts that bond to the inside of the tub side. Stakes could be used to add higher sides to the tub made out of wood, or perhaps supports an "overhead frame" like some off-road trailers have.

2. Different width inner fenders, so people could choose the optimum axle track width for their application, and have inner fenders which didn't waste any space inside the tub by being too large for the track width chosen. Example, a standard Wrangler track width would require inner fenders to protrude about 9" into the tub from each side wall (resulting in abour 42" between the inner fenders; a wider track width could use 5 1/2" inner fenders allowing 49" between them. The mold master is already made for these, just have to make molds for different widths off that master. Or, tiny innner fenders could be done for people who plan to keep the original HF tires/wheels (would anyone keep those tiny tires?)

3, 4. (Never mind, edited these out and forgot to renumber)

5. Hard tonneau cover. For those who want the security of a locking hard cover, this also would be capable of supporting a roof rack and carry loads.

6. Tent platform. Derived from the hard tonneau, this would flip open, doubling the top area of the trailer, and serve as a platform for raising a tent. Inexpensive "ground tents" would be supported, so you could turn this into a tent trailer with this option and a $50 entry-level tent.

7. Side-swinging fiberglass tailgate. Probably for the guys who would put a tent on top of the trailer, a side-swing tailgate may allow easier access to the cargo area than a drop-down.

8. Nerf bars. I posted about them the other day.

9. The "lego" storage pod I posted yesterday.

Now that the base trailer is in the final details and finishing stage, it's time to start thinking about any other features/options I might build for it. Any other options you guys would want?

Last edited: