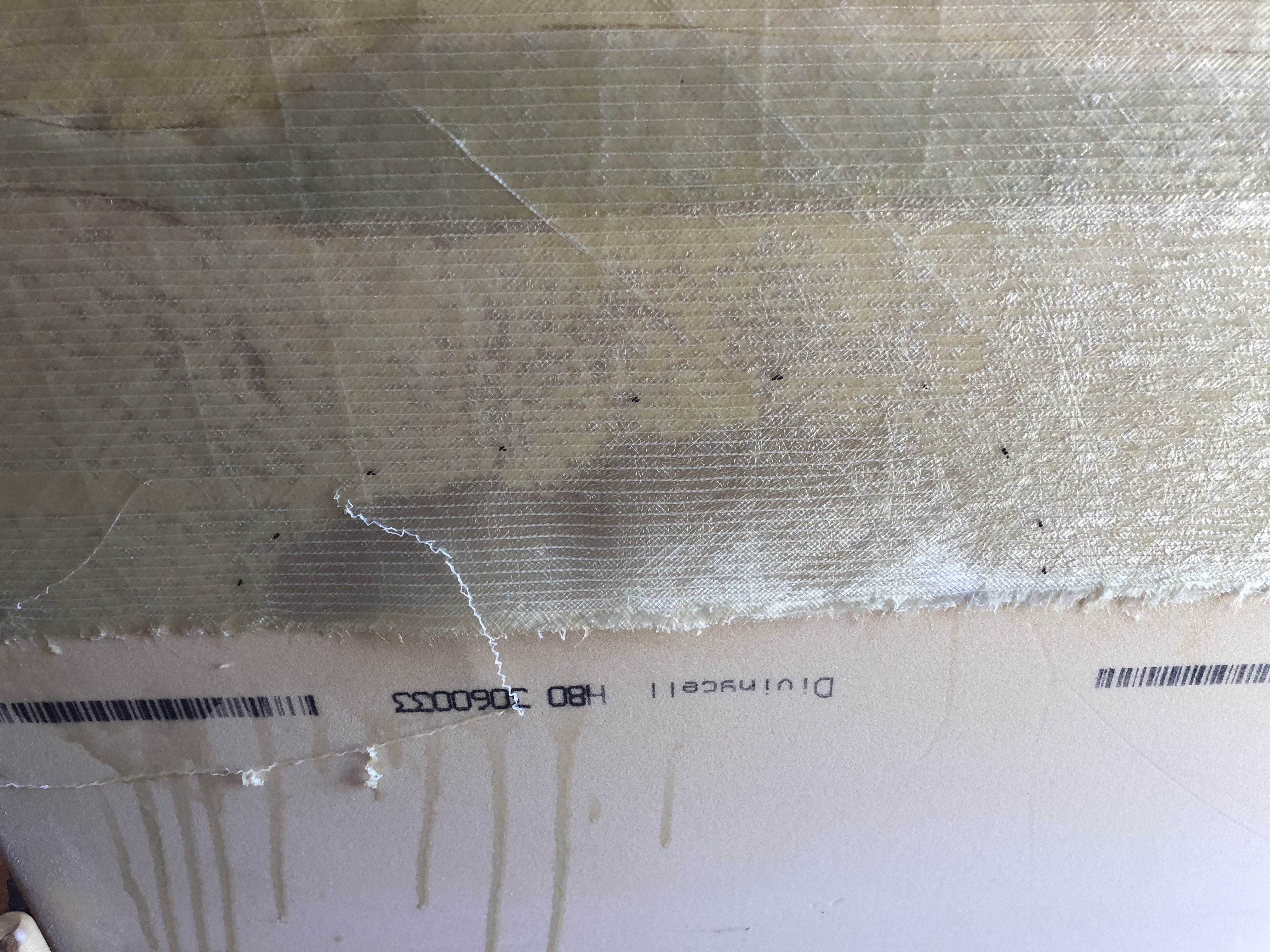

Here's the result of that pile of fiberglass from yesterday's post.

The two small pieces are to finish out the sides of the camper just behind the Oklahoma shaped pieces. The large piece is the cabover floor. We decided to have it angled inboard a few inches on each side, mostly because it will look a lot nicer than a giant box on top of the truck. The oklahoma pieces were laid up with glass in two sections so that the foam could still be bent to fit the contour that we wanted. After finishing the flat pieces, we moved on to some of the exterior joints.

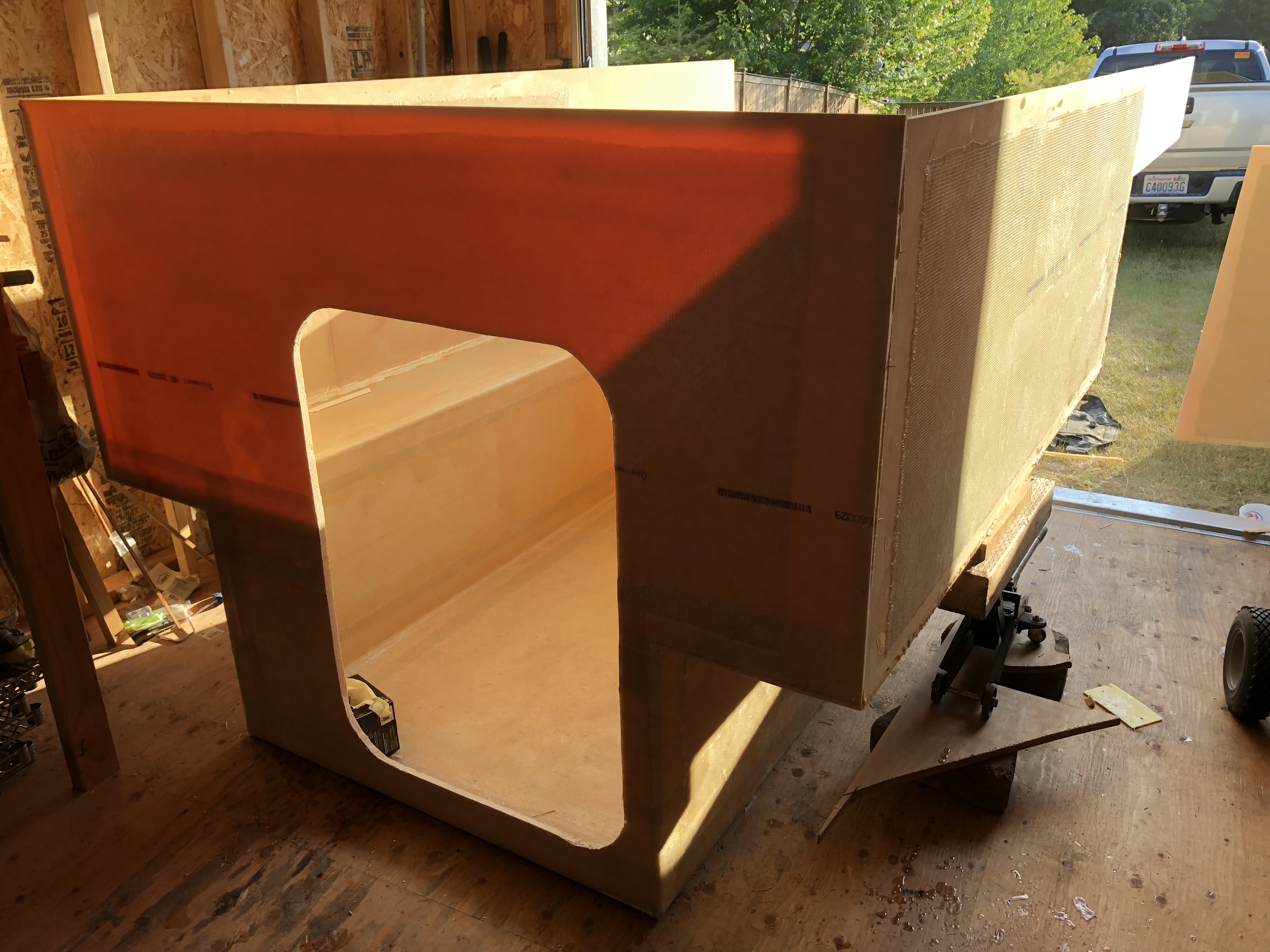

Since everything is so much easier to do when it's laid out flat, we decided to go ahead and glass the entire side bulkhead pieces together.

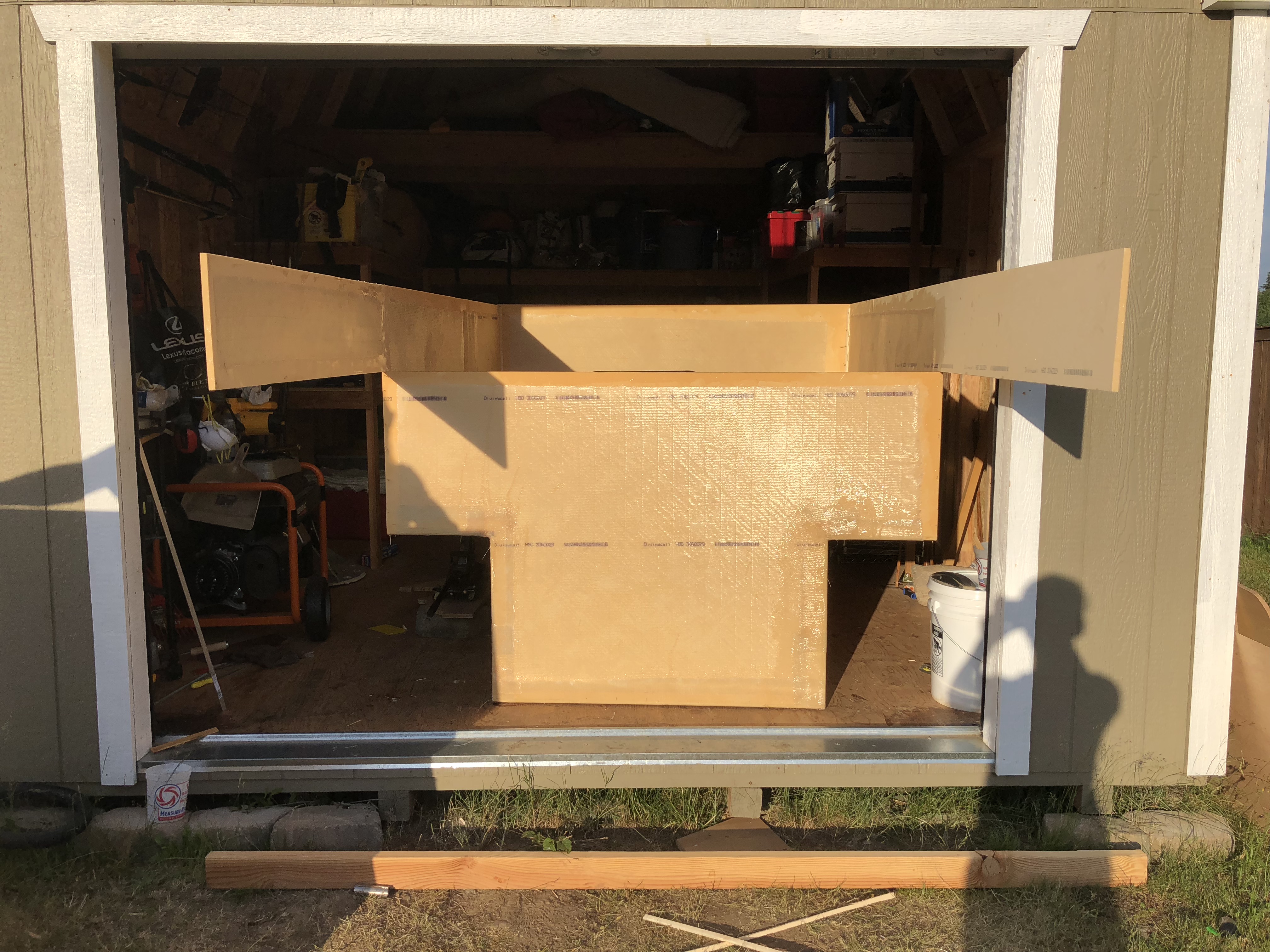

Drying in the yard while we get more snacks.

After waiting for all of the fiberglass to set up (the quick and easy part) we wanted to get all of the pieces glued into place so the glue could set up overnight and be ready for more work the next morning. We used every square and clamp that we own I think. Here's the complete aft bulkhead where the entry door will eventually go.

I used so many toothpicks

Outside in the sun drying and conveniently holding our precut pieces of fiberglass for the next step.

We even got the joints glassed in!

The yard is complete mayhem. The neighbors are starting to get curious as to what we're doing over here.

I'm really glad we decided to do this in the storage shed instead of the attached garage. The chemical smell can be pretty overwhelming sometimes.