Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Converting a factory JK/JKU hardtop to modular

- Thread starter jscherb

- Start date

jscherb

Expedition Leader

Okay, here you go:

The above is in the driver's side corner between the top and the side. I believe that happened from it blowing over a few times. Strangely the other side isn't similarly cracked, so I can only presume it was hitting something only on this side before the other side hit.

Then this is the crack that happened in the rear end collision that precipitated the vehicle getting a new top:

Yeah, I really think that's all it was. But body shops don't really do fiberglass work for insurance jobs. There was a lot of sheet metal bent below this, but apparently standard procedure is to replace this kind of thing. So they transferred all three windows and the wiper hardware from this top to a new one. And the body shop sold this one ultimately for cheap. Which might be a common thing to be able to find.

Here's some more damage on the other front corner:

I don't know how this happened if it wasn't hitting that corner when it fell over. At any rate, I'm not *sure* this is even worth fixing. The scuffed up stuff on top is hidden most of the time, and that corner chipped off the drip rail probably isn't a problem, either. I'd probably just smooth all that out and then just paint it.

But the other cracks are obviously somewhat significant, particularly that corner one.

--Donnie

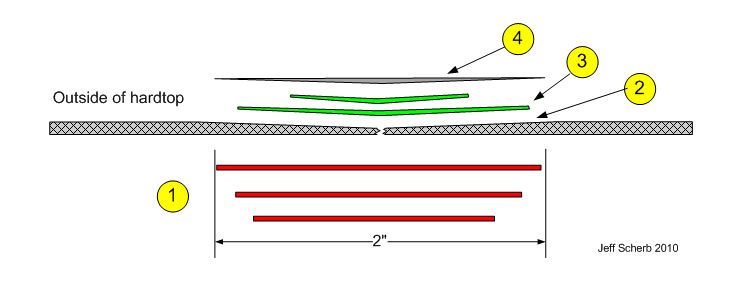

Since the JK hardtop shell is so thin, it's hard to do a structurally sound repair that's invisible on both the inside and outside, so this illustration shows a repair that will be visible on the inside of the top. This illustration is from something I wrote years ago when I was advising someone on the same issue.

1. Rough up the area around the crack on the inside of the hardtop with 80-grit sandpaper. Apply several layers of 1.5 oz. fiberglass mat (red) , saturating with SMC-compatible resin and allow to cure. I've shown the width of the repairs at about 2" on the inside, which should be fine for the cracks in your top, but if the cracks were larger I'd make the repair wider.

2. Sand the outside of the top thinner towards the crack for about 1" on each side of the crack. You want to sand thin enough at the crack to allow two layers of fiberglass mat to be applied so that they’re slightly below the outside surface.

3. Apply two layers of fiberglass mat on the outside of the top with SMC-compatible resin.

4. Apply SMC-compatible body filler and sand level with the original outside surface.

The layers shown in red above are for the structural repair, the layers on the outside of the repair are less for structure and more to prevent the crack from showing through the body filler and paint in the future. You might get away with just body filler and paint on the outside, but if there's any flex in that area of the top in the future it's possible for the crack to reappear in the body filler.

The damage in your last photo I would just fix with SMC-compatible body filler.

To finish the outside of the top, apply a few coats of primer to the repair and finish with matching touch-up paint. The repaired area won't be textured anymore, Sometimes it's possible to use a rattle-can texture paint to approximately match the texture, this can be applied over the primer but before the final paint coat. A very thin coat of texture paint sprayed from a longer distance than you'd ordinarily spray from sometimes works best, but it's very difficult to really get an invisible match to the texture.

jscherb

Expedition Leader

Love that snap-in hard/soft window idea if it can be done in a manner that seals well...

I've worked up designs for both the soft window and the hard window that I'm confident will seal well, but I'll have to build prototypes to prove that.

the soft windows on a hardtop would be cool- especially if you could also put in glass windows or even screens depending on your adventure.

Hadn't thought about screens, but snap-in screens could be done as well.

jscherb

Expedition Leader

Could you somehow modify and use a soft top door surround?

You could try, but it might be more difficult than you think. The plastic they're made of doesn't accept adhesives very well, so you wouldn't be able to make modifications to it that require adhesive. You'd need a flange on the top edge, for example, to bolt it to the underside of the roof panel so that would probably have to be bolted or pop-riveted on. You'd also need to figure out how to secure the soft side to it; the back edge of the factory surround tapers down pretty narrow towards the bottom so the aluminum retainer strip method I've used on the fiberglass parts wouldn't adapt well to a modified factory surround without some modification.

Also you probably don't want to use the same method the factory soft top panels use to attach to the surround unless you want to give up the roll-up feature, the plastic angle strip that's used for that doesn't roll up. I posted a roll-up mod for factory soft top windows a while back, it leaves the plastic angle in place and inserts a zipper in the soft top panel. I suppose if you wanted to use the factory plastic angle method to attach a roll-up side panel to a modified factory surround you could zipper the panel like I did with that mod:

All things considered, I'd prefer modifying the fiberglass panel as I originally showed rather than try to modify a factory plastic surround.

jscherb

Expedition Leader

I was definitely thinking bolt-on flanges for those of us without fiberglassing skills, with the zipper mod.

Of course, yours is more...elegant. :ylsmoke:

I just compared a factory surround to a modular modified side panel to see exactly what would be involved, and the location of the hinge on the factory surround is at best inconvenient for this application. A few photos:

I guess you'd have to use the vertical piece and part of the horizontal piece, but the hinged area doesn't really allow space for a flange or bolts to secure it to the underside of the roof panel, so some thought would have to go into how this might be able to be modified to work, it isn't as simple as just cutting it and bolting a flange onto the top.

jscherb

Expedition Leader

Here's a little more info snap-in window idea, I'm working on the weatherstrip details for the soft window and the hard window.

In this photo I've set a few snap studs in place to check the clearances:

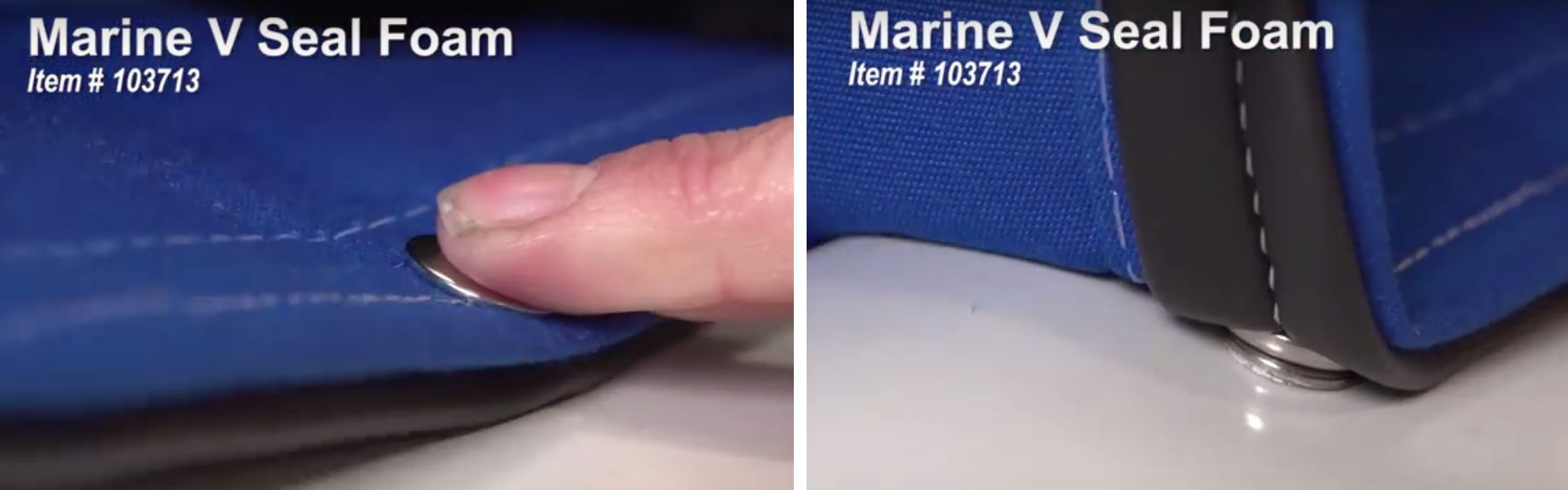

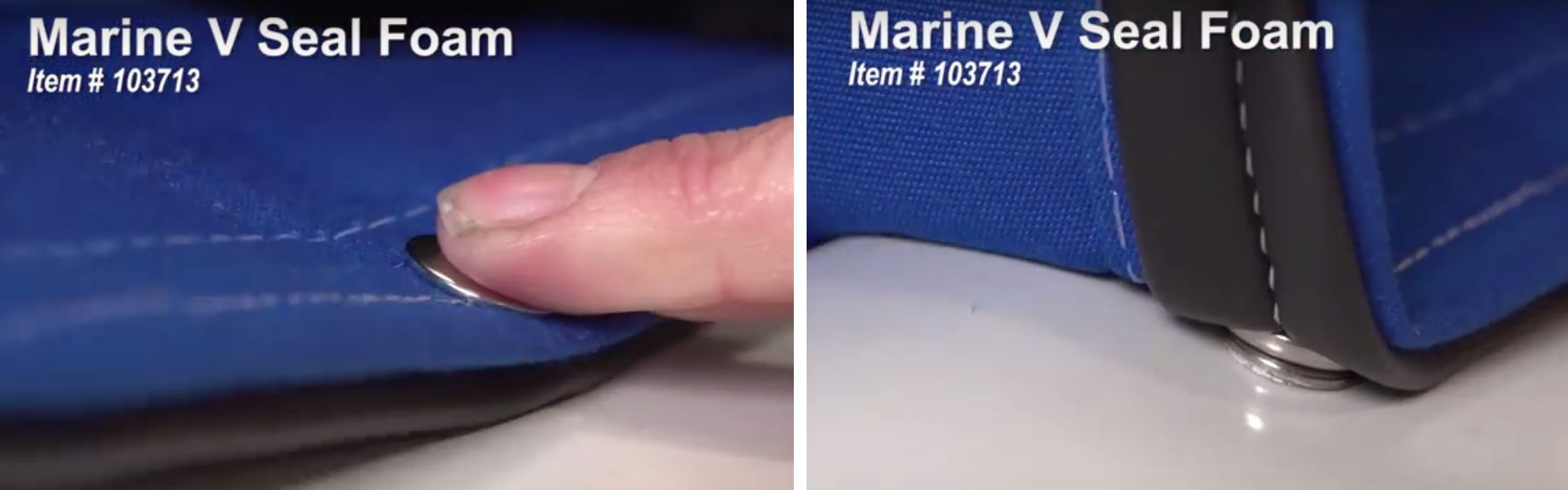

The soft window would be weatherstripped with Marine V-Seal foam from SailRite. It's designed to seal around snaps:

The hard window would be weatherstripped with a push-on trim seal like this sample on a small scrap of Lexan:

The trim seal for the hard window won't conflict with the snap-studs for the soft window, there's just enough clearance between the stud and where the hard window weatherstrip needs to seal, which allows both soft and hard windows to be interchangeable. The hard window wouldn't use the snaps, it would be secured with latches from the inside.

The hard window would be Lexan, for two reasons - first, doing custom windows with compound curves would be cost-prohibitive, and second, Lexan windows wouldn't need any special care when they're removed, except perhaps putting them in a storage bag to prevent scratches, but you would be able to just throw them in the back of the Jeep in the bag without worrying about breakage like you would with glass windows.

It would also be possible to use the same push-on weatherstrip with the factory glass, but the problem would be finding a strong enough way to bond the latches to the glass.

A screened soft window to keep dogs in could be done the same as a clear vinyl soft window, just with fiberglass screen in place of the vinyl.

The original snap-in soft window concept images:

In this photo I've set a few snap studs in place to check the clearances:

The soft window would be weatherstripped with Marine V-Seal foam from SailRite. It's designed to seal around snaps:

The hard window would be weatherstripped with a push-on trim seal like this sample on a small scrap of Lexan:

The trim seal for the hard window won't conflict with the snap-studs for the soft window, there's just enough clearance between the stud and where the hard window weatherstrip needs to seal, which allows both soft and hard windows to be interchangeable. The hard window wouldn't use the snaps, it would be secured with latches from the inside.

The hard window would be Lexan, for two reasons - first, doing custom windows with compound curves would be cost-prohibitive, and second, Lexan windows wouldn't need any special care when they're removed, except perhaps putting them in a storage bag to prevent scratches, but you would be able to just throw them in the back of the Jeep in the bag without worrying about breakage like you would with glass windows.

It would also be possible to use the same push-on weatherstrip with the factory glass, but the problem would be finding a strong enough way to bond the latches to the glass.

A screened soft window to keep dogs in could be done the same as a clear vinyl soft window, just with fiberglass screen in place of the vinyl.

The original snap-in soft window concept images:

Jeep or Tacoma

Explorer

excellent

I loved the write up and the detail. I am not sure I would want to tackle the project my self as I am not sure I am skilled enough or patient enough, I would love to hear you ideas on some sort of carpet top for the JKU. I see the ursa minor and think those are great! also the new ones from AT in arizona. while I would love to own anyone those the price is torch for me right now. Being over 60 I need to get up in the night and would like not to have to leave the vehicle. maybe you have thought about some variants on this theme "roof top camping" That are not being done right now. Seems to me that if you could install fold down tailgate ( I know they are available) you could perhaps create along standing area with a similar concept to Ursa minor j130 I would love to hear what you thought about or perhaps will think about. anyway excellent job, excellent write up, and very enjoyable reading about the process!

I loved the write up and the detail. I am not sure I would want to tackle the project my self as I am not sure I am skilled enough or patient enough, I would love to hear you ideas on some sort of carpet top for the JKU. I see the ursa minor and think those are great! also the new ones from AT in arizona. while I would love to own anyone those the price is torch for me right now. Being over 60 I need to get up in the night and would like not to have to leave the vehicle. maybe you have thought about some variants on this theme "roof top camping" That are not being done right now. Seems to me that if you could install fold down tailgate ( I know they are available) you could perhaps create along standing area with a similar concept to Ursa minor j130 I would love to hear what you thought about or perhaps will think about. anyway excellent job, excellent write up, and very enjoyable reading about the process!

jscherb

Expedition Leader

I loved the write up and the detail. I am not sure I would want to tackle the project my self as I am not sure I am skilled enough or patient enough, I would love to hear you ideas on some sort of carpet top for the JKU. I see the ursa minor and think those are great! also the new ones from AT in arizona. while I would love to own anyone those the price is torch for me right now. Being over 60 I need to get up in the night and would like not to have to leave the vehicle. maybe you have thought about some variants on this theme "roof top camping" That are not being done right now. Seems to me that if you could install fold down tailgate ( I know they are available) you could perhaps create along standing area with a similar concept to Ursa minor j130 I would love to hear what you thought about or perhaps will think about. anyway excellent job, excellent write up, and very enjoyable reading about the process!

If I were to do a JKU camper, I wouldn't start with factory hardtop parts, I'd probably use my TrailTop modular camper components and maybe do something like this:

But that's way off-topic for this thread. The TrailTop components are in this thread: http://www.expeditionportal.com/for...ot-modular-trailer-topper-building-components

jscherb

Expedition Leader

This is a GREAT thread. Thank you for putting so much time into writing up what seems to be a very small project for you. Being able to have a shorter and more concise thread to learn more about fiberglass and composites was a great primer for me.

Thanks, I'm glad you found it useful. This thread barely scratches the surface of what's possible with fiberglass for our Jeeps and trailers, but this is a good starter project for someone who's never done anything with composites before (especially if you reduce the first-time anxiety factor by doing the surgery on a used hardtop you picked up cheap

Another good source of information is this book:

http://www.barnesandnoble.com/w/fib...1498-forbes-aird/1118482410?ean=9781557884985.

It's likely that your local library has a book or two on fiberglass boat building, and while often library books on this subject are from the 70's or even earlier, the information in them still applies, especially to doing fiberglass at home.

And of course I'm always available to answer any questions about fiberglass anyone might have.

Metcalf

Expedition Leader

Thanks, I'm glad you found it useful. This thread barely scratches the surface of what's possible with fiberglass for our Jeeps and trailers, but this is a good starter project for someone who's never done anything with composites before (especially if you reduce the first-time anxiety factor by doing the surgery on a used hardtop you picked up cheap).

Another good source of information is this book:

http://www.barnesandnoble.com/w/fib...1498-forbes-aird/1118482410?ean=9781557884985.

It's likely that your local library has a book or two on fiberglass boat building, and while often library books on this subject are from the 70's or even earlier, the information in them still applies, especially to doing fiberglass at home.

And of course I'm always available to answer any questions about fiberglass anyone might have.

Thank you, I will stick that on my list to read.

On my truck project, I am actually trying to steal a few techniques from the fiberglass world to help me make the top panel out of metal. I really want, for no other reason than to say I have done it, to make a new top panel for my FJ45-esk truck tub in one piece of aluminum sheet. It is just a personal challenge. I don't have anything against fiberglass...and in the end I will probably wish I would have just done it out of 'glass! I like a challenge however. The part is modular to the body so I can try a few different methods if one fails.

What I am basically going to do is make a male plug in the shape I need, minus the drip rail. Then use that male plug to make a female flow forming mold. I am going to try to build an edge for forming the drip rail into the female mold. I will likely need to shrink at the corners a bit. I have a shrinker, but that will have to wait till I get the part out of the mold....

The plug process, in foam/wood, is what I have been researching the most lately. If you have any details/tips about how to do that well, I would love to hear them. My basic thought right now is to make the plug out of laminated MDF with a lot of sanding to get the shape right. I think I can get that far ok. My main questions are about how to seal the surface of the plug, surface finishes, etc. Then, what is the best process ( mold wax? ) to make sure the plug releases from the mold.

Thank you for any help, feel free to move this conversation over to my build thread here....

http://www.expeditionportal.com/for...-FZJ80-FJ45esk-GM-Land-Rover-crazy-concoction

jscherb

Expedition Leader

Thank you, I will stick that on my list to read.

On my truck project, I am actually trying to steal a few techniques from the fiberglass world to help me make the top panel out of metal. I really want, for no other reason than to say I have done it, to make a new top panel for my FJ45-esk truck tub in one piece of aluminum sheet. It is just a personal challenge. I don't have anything against fiberglass...and in the end I will probably wish I would have just done it out of 'glass! I like a challenge however. The part is modular to the body so I can try a few different methods if one fails.

What I am basically going to do is make a male plug in the shape I need, minus the drip rail. Then use that male plug to make a female flow forming mold. I am going to try to build an edge for forming the drip rail into the female mold. I will likely need to shrink at the corners a bit. I have a shrinker, but that will have to wait till I get the part out of the mold....

The plug process, in foam/wood, is what I have been researching the most lately. If you have any details/tips about how to do that well, I would love to hear them. My basic thought right now is to make the plug out of laminated MDF with a lot of sanding to get the shape right. I think I can get that far ok. My main questions are about how to seal the surface of the plug, surface finishes, etc. Then, what is the best process ( mold wax? ) to make sure the plug releases from the mold.

Thank you for any help, feel free to move this conversation over to my build thread here....

http://www.expeditionportal.com/for...-FZJ80-FJ45esk-GM-Land-Rover-crazy-concoction

I've done a number of forms for roof panels, but none were intended for the stress of forming metal, so my construction techniques probably wouldn't help you. The most recent one was the roof for the JK Safari Cab project, I posted a lot of detail on the roof form construction in that thread.

Similar threads

- Replies

- 4

- Views

- 1K

- Replies

- 0

- Views

- 1K

- Replies

- 4

- Views

- 2K

- Replies

- 64

- Views

- 12K