You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Diesel for overlanding- are you happy with the choice?

- Thread starter GreggNY

- Start date

Again, ignorance. There is life beyond the US borders, believe it or not.

This is a global industry, changes beyond the US borders directly effect that of the US.

Many places already have in effect diesel bans, and many more are on the horizon.

https://dearman.co.uk/media/global-diesel-ban-and-restrictions-updates/

I love how people have to resort to quoting these odd and random sources.

For the record, certain EU cities are banning older diesel engines. The newer Euro-5 and Euro-6 emissions compliant diesels are widely accepted, and widely used, in the EU. Also, some European OEM's are shifting away from diesel cars (though they are still very prevalent), but diesel trucks, 4x4's and commercial vehicles are still very much the norm in Europe and throughout the world.

IdaSHO

IDACAMPER

Doesn't matter. It all starts somewhere.

This is a whole lot bigger than production numbers and sales of vehicles.

This is about a global shift in the opinion of diesel, primarily due to emissions.

Some of the industry is already shifting away from diesel.

The only reason large commercial trucks havnt yet (as well as most commercial traffic) is simply because there isnt a decent alternative yet.

Once there is.... diesel will be in real trouble.

But I know you argue just to argue, so please carry on...

This is a whole lot bigger than production numbers and sales of vehicles.

This is about a global shift in the opinion of diesel, primarily due to emissions.

Some of the industry is already shifting away from diesel.

The only reason large commercial trucks havnt yet (as well as most commercial traffic) is simply because there isnt a decent alternative yet.

Once there is.... diesel will be in real trouble.

But I know you argue just to argue, so please carry on...

REDROVER

Explorer

Dude you really hate diesel,

I am assuming you can’t afford one,

u been smoked by one

Or u are just butt hurt that it’s an amazing engine and I don’t have one.

u dwell on some articles about diesel going away, I am f.in European I travel there every year, keep your Fake propaganda to yourself,

look at the market, every automaker now makes diesel, even race cars by Audi are working on new Diesel engine.

Due to the fact that diesel is compression ignition, it leaves a lot less carbon footprint compared to your beloved gasoline.

I am out. Have fun with your spark ignition.

Eric

I am assuming you can’t afford one,

u been smoked by one

Or u are just butt hurt that it’s an amazing engine and I don’t have one.

u dwell on some articles about diesel going away, I am f.in European I travel there every year, keep your Fake propaganda to yourself,

look at the market, every automaker now makes diesel, even race cars by Audi are working on new Diesel engine.

Due to the fact that diesel is compression ignition, it leaves a lot less carbon footprint compared to your beloved gasoline.

I am out. Have fun with your spark ignition.

Eric

Buliwyf

Viking with a Hammer

Audi's diesel got it's ******** kicked this year, by a more efficient gas v8. Did they even show up to Lemans? Nope. Because they're sissys. They couldn't handle coming in second place. That's really bad for motorsport, and absolutely disgraceful. Toyota beat them so soundly that they wouldn't even show up. I'm being a bit harsh on them, but whatever. They could have at least sent out a budget team with last years Audi or Porsche.

Have fun on the side of the road. I can have any engine that I want. Diesel just won't function well in a weekend warrior truck.

Have fun on the side of the road. I can have any engine that I want. Diesel just won't function well in a weekend warrior truck.

Last edited:

IdaSHO

IDACAMPER

Dude you really hate diesel,

Neither love nor hate. But I do observe the market without complete ignorance.

FYI, I own both turbo diesel and gasser Ford trucks.

I have to laugh at all of this talk about more medium duty trucks and rv being ordered with gas motors as if it's because they do the job better. It's because the diesel costs $10k more. That's it. No more no less. It's an economic decision, period. To argue otherwise is ignorance at its best.

A gas motor does not move a 15 or 20,000# class A better than a diesel. It just doesn't. It's not more comfortable. It doesn't get better mileage. It's cheaper to buy and that's what buyers want.

As for the fleet medium duty trucks, the gas motors have finally caught up to where they will last as long as the rest of the truck. When the truck is dead, the engine is still running fine. That's all that matters. Back when the gas engines wore out before the chassis did, they ordered diesel. They no longer have to.

A gas motor does not move a 15 or 20,000# class A better than a diesel. It just doesn't. It's not more comfortable. It doesn't get better mileage. It's cheaper to buy and that's what buyers want.

As for the fleet medium duty trucks, the gas motors have finally caught up to where they will last as long as the rest of the truck. When the truck is dead, the engine is still running fine. That's all that matters. Back when the gas engines wore out before the chassis did, they ordered diesel. They no longer have to.

Wallygator

Adventurer

And yet Ford's bringing a big block gas engine to market.

That slides right in perfectly between the current gas engine, and the diesel, powerwise. To give medium duty local trucks a better option. And to give glampers a better option, if they only glamp a few weeks every year. Or want, not need, more power. Like 90% of the diesel glampers out there.

Already seeing more and more GM/PSI 8.8l gas engines in medium duty trucks.

The Godzilla is gonna be huge in the fleet sales market. I will be looking hard at this truck in a few years. It makes a lot of sense for me.

nickw

Adventurer

Diesels are most certainly devolving from a "simplicity" perspective, but then again so are gasoline engines (cylinder de-activation, direct injection, turbo's, increasingly complex ignition and timing strategies). So pick your poison. None of these modern engines are ones that can be diagnosed and fixed on the roadside, unless you happen to be a trained mechanic with thousands of dollars of equipment and software at your disposal. As EV, hybrid and fuel-cell vehicles become more prominent, that trend will only continue.

As for the "tide" shifting, I have no idea what people are basing that off of. Diesels are still far and away the preferred choice for 4x4's in overseas markets. Emissions controls and ULSD are quickly being adopted by many of those countries. Historically, diesel in North America never really had any discernible market share outside of 3/4 ton and commercial markets for a number of reasons. Nowadays, we have diesel midsize trucks and 1/2 ton's, in addition to the 3/4 tons and commercial market....and more on the way. So why some people think OEM's are going to shift away from diesel engines, after they've already made significant investments and gains in that technology is beyond my comprehension.

Also, you don't need to tow +12klb loads in order to "justify" diesels. They offer a tangible (and felt) advantage in terms of torque which is relevant to hauling heavy payloads and just driving through various types of terrain. If you don't want the cost associated with a 1000lb-ft 3/4 ton diesel, there are much more economical diesel options out there. It's foolish to imply that diesels are only useful for towing heavy loads...that argument fails to appreciate just how useful low-end torque is for most 4x4 applications.

You guys are mixing and matching the reliability and longevity of old school diesels with the performance of new diesels. You can't have it both ways. If you wanna tout longevity, you can have your BJ60 with your 90hp 3B engine or your new LC70 with a 130hp 1HZ, you'll get 300,000+ trouble free miles, buy you have a rig that will be worthless in the "modern" world with all the towing, hauling, 80mph commutes and acceleration to get in front of traffic that is needed.

You may be right, diesels will evolve and get more emissions controls and may still have a market....but the reliability issue will continue to get worse.

Offroad is the one place where you DO NOT need a diesel.

I always get a good laugh out of the Torque discussions....as long as you have the power where you need it @ a certain RPM you are good. Diesels have power lower in the RPM range where gas generally in the upper RPM, pick your poison and gear accordingly....there are benefits to both, but you certainly can't say more torque is better.

nickw

Adventurer

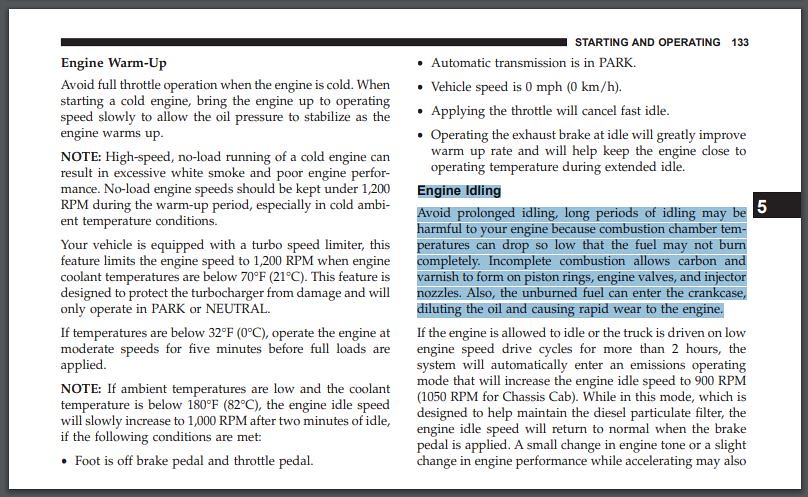

Just pesky little places like the owners manual.

http://owners.mopar.ca/en/manuals/2017/2017E-RAM_15_25_35_45_55-Diesel-OM-SU-1st.pdf

page 133

Interesting - didn't realize the OEM's advised against it, nice find.

Adventurous

Explorer

That is a nice find. I was unaware of it as well, but seldom idle my vehicle for long periods of time, so I'm largely unaffected.

Of course, I was also unaware of the idling recommendations pre-shutdown, so it would appear as if I should go through the diesel supplement again and read it more carefully.

Of course, I was also unaware of the idling recommendations pre-shutdown, so it would appear as if I should go through the diesel supplement again and read it more carefully.

IdaSHO

IDACAMPER

As emissions have become more stringent, MFGs have resorted to running engines hotter, and hotter.

Always a good idea to idle for a while (or drive conservatively) to allow oil temps to come down after a hard pull.

Turbocharged vehicles especially (oil cooled/lubricated turbos)

Always a good idea to idle for a while (or drive conservatively) to allow oil temps to come down after a hard pull.

Turbocharged vehicles especially (oil cooled/lubricated turbos)

luthj

Engineer In Residence

Interestingly, one of the primary drivers of idle issues with diesels is soot accumulation in the intake and EGR tract. This is because the excess air at low load idle means lots of NOx production. To combat this, the EGR flow will be high. This reduces free O2 for NOx production. However the low flow rates in the tracts/tubes gives soot much more time to deposit, and thus produce the oil/soot cakes that cause trouble. Lower combustion temps at idle also mean higher soot production in general, combined with low EGTs, the DPF is not likely to regen properly. Hence the need for regular driving. For fuel efficiency, lower soot, and DPF regen high combustion temps are desirable. However, NOx rapidly increases with EGT (square of the temp change). So its a complex balancing game. The addition of SCR (urea catalytic reduction) has helped quite a bit, by allowing higher combustion temps, and still keeping NOx under control.

I am a trained powerplant engineer, and have some design experience. The idea that the diesel engine cycle (as opposed to the Otto cycle) is somehow inherently better is kinda ridiculous. Yes its slightly more efficient volumetrically, but much of that savings is wiped out by emissions scrubbing needs. There is no reason that a gasoline/Otto powerplant cannot perform the same tasks with equivalent reliability. In fact its fairly easy to engineer a gas powerplant to make similar torque down low. This is rarely done because it serves little benefit with a proper transmission. Diesel engines have slightly different needs geometrically, so they will generally produce more torque at low RPM. Because diesel fuels flame front speed is so slow, they are generally limited to about 4800rpm with cylinders up to 700cc, and well under 3000rpm at sizes over 1.2 liters per cylinder. Thus in order to make good power they must be turbocharged, to get maximum fuel per second at low RPM. This means heavier everything, from pistons to heads. More weight, more cost, etc.

For the same compression ratio, the otto cycle is actually more efficient than the diesel cycle. However, with gasoline auto-igniting much more easily, it has compression limits that don't apply to diesel cycle engines. However on the horizon are homogeneous charge compression ignition engines using gasoline. GDI technology has allowed compression ratios to rise further, improving efficiency in gasoline powerplants.

Diesels still have market in heavy transport. This is due to higher overall efficiency. In applications burning 100+ gallons per day, the savings adds up. In some industries the higher energy density of diesel has significant value as well.

I also find it quite funny when heavily emotionally invested folks argue that diesel is good because (insert random old engine/vehicle here). Heck, if I wanted to argue for the superiority of gas powerplants, I could pick any number of legendary engines from the last 30 years. We are talking modern on the lot engines with real world operating conditions. Not deleted/tuned units, not "bulletproofed" etc.

Its a typical mindset, that all non-proponents, must be opponents or enemies. Most of the non proponents in this thread aren't bashing diesels. They are just pointing out obvious economic, emissions, and reliability issues. Then again, for most its human nature to defend the position you've chosen, regardless of evidence. Doing so makes us feel good, as we are "winning/fighting" against the opposition. Even big fleets are that way at times, though eventually the almighty dollar begins to win out over tradition.

I am a trained powerplant engineer, and have some design experience. The idea that the diesel engine cycle (as opposed to the Otto cycle) is somehow inherently better is kinda ridiculous. Yes its slightly more efficient volumetrically, but much of that savings is wiped out by emissions scrubbing needs. There is no reason that a gasoline/Otto powerplant cannot perform the same tasks with equivalent reliability. In fact its fairly easy to engineer a gas powerplant to make similar torque down low. This is rarely done because it serves little benefit with a proper transmission. Diesel engines have slightly different needs geometrically, so they will generally produce more torque at low RPM. Because diesel fuels flame front speed is so slow, they are generally limited to about 4800rpm with cylinders up to 700cc, and well under 3000rpm at sizes over 1.2 liters per cylinder. Thus in order to make good power they must be turbocharged, to get maximum fuel per second at low RPM. This means heavier everything, from pistons to heads. More weight, more cost, etc.

For the same compression ratio, the otto cycle is actually more efficient than the diesel cycle. However, with gasoline auto-igniting much more easily, it has compression limits that don't apply to diesel cycle engines. However on the horizon are homogeneous charge compression ignition engines using gasoline. GDI technology has allowed compression ratios to rise further, improving efficiency in gasoline powerplants.

Diesels still have market in heavy transport. This is due to higher overall efficiency. In applications burning 100+ gallons per day, the savings adds up. In some industries the higher energy density of diesel has significant value as well.

I also find it quite funny when heavily emotionally invested folks argue that diesel is good because (insert random old engine/vehicle here). Heck, if I wanted to argue for the superiority of gas powerplants, I could pick any number of legendary engines from the last 30 years. We are talking modern on the lot engines with real world operating conditions. Not deleted/tuned units, not "bulletproofed" etc.

Its a typical mindset, that all non-proponents, must be opponents or enemies. Most of the non proponents in this thread aren't bashing diesels. They are just pointing out obvious economic, emissions, and reliability issues. Then again, for most its human nature to defend the position you've chosen, regardless of evidence. Doing so makes us feel good, as we are "winning/fighting" against the opposition. Even big fleets are that way at times, though eventually the almighty dollar begins to win out over tradition.

Last edited:

nickw

Adventurer

Interestingly, one of the primary drivers of idle issues with diesels is soot accumulation in the intake and EGR tract. This is because the excess air at low load idle means lots of NOx production. To combat this, the EGR flow will be high. This reduces free O2 for NOx production. However the low flow rates in the tracts/tubes gives soot much more time to deposit, and thus produce the oil/soot cakes that cause trouble. Lower combustion temps at idle also mean higher soot production in general, combined with low EGTs, the DPF is not likely to regen properly. Hence the need for regular driving. For fuel efficiency, lower soot, and DPF regen high combustion temps are desirable. However, NOx rapidly increases with EGT (square of the temp change). So its a complex balancing game. The addition of SCR (urea catalytic reduction) has helped quite a bit, by allowing higher combustion temps, and still keeping NOx under control.

I am a trained powerplant engineer, and have some design experience. The idea that the diesel engine cycle (as opposed to the Otto cycle) is somehow inherently better is kinda ridiculous. Yes its slightly more efficient volumetrically, but much of that savings is wiped out by emissions scrubbing needs. There is no reason that a gasoline/Otto powerplant cannot perform the same tasks with equivalent reliability. In fact its fairly easy to engineer a gas powerplant to make similar torque down low. This is rarely done because it serves little benefit with a proper transmission. Diesel engines have slightly different needs geometrically, so they will generally produce more torque at low RPM. Because diesel fuels flame front speed is so slow, they are generally limited to about 4800rpm with cylinders up to 700cc, and well under 3000rpm at sizes over 1.2 liters per cylinder. Thus in order to make good power they must be turbocharged, to get maximum fuel per second at low RPM. This means heavier everything, from pistons to heads. More weight, more cost, etc.

For the same compression ratio, the otto cycle is actually more efficient than the diesel cycle. However, with gasoline auto-igniting much more easily, it has compression limits that don't apply to diesel cycle engines. However on the horizon are homogeneous charge compression ignition engines using gasoline. GDI technology has allowed compression ratios to rise further, improving efficiency in gasoline powerplants.

Diesels still have market in heavy transport. This is due to higher overall efficiency. In applications burning 100+ gallons per day, the savings adds up. In some industries the higher energy density of diesel has significant value as well.

I also find it quite funny when heavily emotionally invested folks argue that diesel is good because (insert random old engine/vehicle here). Heck, if I wanted to argue for the superiority of gas powerplants, I could pick any number of legendary engines from the last 30 years. We are talking modern on the lot engines with real world operating conditions. Not deleted/tuned units, not "bulletproofed" etc.

Its a typical mindset, that all non-proponents, must be opponents or enemies. Most of the non proponents in this thread aren't bashing diesels. They are just pointing out obvious economic, emissions, and reliability issues. Then again, for most its human nature to defend the position you've chosen, regardless of evidence. Doing so makes us feel good, as we are "winning/fighting" against the opposition. Even big fleets are that way at times, though eventually the almighty dollar begins to win out over tradition.

Great contribution, thanks for sharing....

Similar threads

- Replies

- 19

- Views

- 1K

- Replies

- 1

- Views

- 961

- Replies

- 33

- Views

- 6K