I'm sure I can probably save some money by diy a bunch of it. Given a14 ft box, I would need a bit more than just some poly isolators based on my math.

Can do 3 or 4 point pivoting, and spread the load out much better than single point bushings.

Since you probably want your camper and cab attached, a "3 point" arrangement with the front "fixed" would be best. That's how mine is. Space the front ones wide, and the rest would be on a centerline, so you'd need to bridge across the frame rails for those. I'm using Energy Suspension universal isolators (soft compound) and they are ~$20 each, and I'd recommend a max of ~400 lbs per. You can have multiples on each bridge member, but they need to be on a lengthwise centerline.

Sorry about this... I tried to post a link to my post, but it insists on embedding it for some reason...

Interesting concept - do you have any photos?

This will have to do for now. Basically where you want pivoting to occur the isolators need to be in a line. Can do 3 point or 4 point easily enough. These are the soft Energy Suspension universal body mount bushings, cost ~$20 each now. Though I was told these would take a static load of 800 lbs each, that might be optimistic.

I don't know the details on how GT make the floor of their box... but TC uses thick pultruded square fiberglass tubes embedded in their floors at attachment points, and those would be plenty strong.

Totally understand if you just want GT to make all of it and not think about it. IME... I end up regretting that... because it turns out the fabricator I counted on to do the thinking, really didn't...

As far as the overhang goes I'm aware that it will produce limitations. But that's the trade-off I need to make in order to have something that I can full-time in with a child, and a reasonable level of comfort. I don't do hardcore wheeling, and really avoid true 4x4 routes most of the time. But decent ground clearance and the ability to drive out of the occasional screw up are important. If I really need more departure anangle, I'll uprate to 37 or 38in tires. Currently planning on 34/35" singles.

Longer wheelbase? 176 vs 158 would help a lot.

Your info posted at #4 doesn't change the overhang for the wheelbase, and the load height is surely wrong. Do you have an estimate of what you camper floor height will be above the ground?

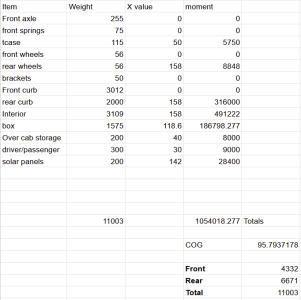

Did some weight distribution math, looks like my planned 14ft box will just work weight wise. This includes the weight of a 4x4 conversion, and 34" wheels and tires, plus water, food, passengers etc. Load range F tire is good for 7940lb, so there is a bit of margin. I would like a touch more weight on the front axle, but there isn't much to be done with a 158"WB and a longer box.

View attachment 899054

That seems off, even with a 158" wheelbase, unless there is a lot of heavy stuff behind the rear axle. The chassis is very biased to the front, and at the camper floor you have ~100" in front of the rear axle, and 69" behind.