jayshapiro

Adventurer

The Fun Stuff

Just because you're environmentally friendly, doesn't mean you have to be boring...

One of the other things we did over the past couple of months was to design and configure the audio/video system for the vehicle. We're going to be spending a LOT of time in this truck, so we wanted to make sure that we had a way of taking all our tunes, and our toons with us. (two small kids!)

I started by thinking about where we would want to listen / watch our content, and then worked backwards from there. I knew we didn't want to carry around hundreds of CD's / DVD's with us, so a Hard-Drive media vault became obvious. Then, once we had that central storage concept, the question started to be about where should that be and how do we interconnect everything.

In the end, we came up with a pretty cool solution. Although we rarely talk electronics on ExPo, I thought it would be worth detailing for those interested.

We started with an InFill T3 in-dash PC. This takes the place of 2 DIN spots in the dash (same as my factory Ford radio) but manages to squeeze in a Windows XP PC, with a 40GB shock mounted hard drive and DVD drive. They are made in Korea and look like this:

Connected to this is a 1 Terrabyte (Yippee!) Western Digital USB Hard Drive mounted in foam in the centre console. I can't believe how cheap these are now. I got mine at Best Buy for about $230. We're in the process of ripping all our DVD's and MP3's to the drive. We'll never fill it...

The PC also has built in WiFi and we'll hook up my Cingular unlimited Data GSM card, and just get pre-paid SIM's as we travel around.

Then I found this amazing deal on HUGE 10.5" headrest monitors, with built in DVD/SD-card players from "GoodDeals18.com" - I was nervous ordering them as I'd never heard of the shop before, but they arrived exactly as promised and they're amazing. An F-650 is probably the only truck they wouldn't look huge in though!

The system is prewired to take inputs from our laptop on the Jotto Desk in the passenger seat if we want to play music from there too...

BUT... we're going to be spending most of our evenings back in the camper, so we also pre-wired the system to feed audio/video signals back to the LCD TV in the camper, and allow for a possible second one in the outdoor kitchen cabinet at some point in the future if we want to. These can be controlled by the RF Wireless keyboard and mouse from inside the camper.

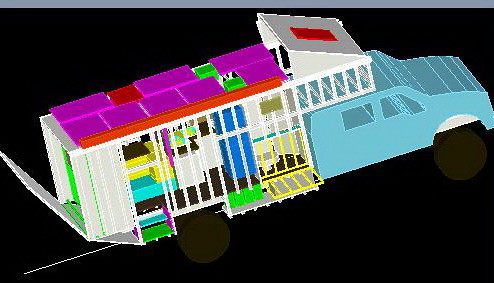

The whole system then looks like this:

I'm a bit of a geek still at heart, so designing this part of the truck has been great fun. It's a lot of technology in an off-road rig, and we'll see how well it all holds up to the dust & vibrations on the trip - but I think it should be ok.

It is certainly a lot of complexity / money to invest in music / TV / Connectivity, but I justify by remembering that we're going to be spending 2 years in this thing with kids. We're certainly going to appreciate nature and sit around the campfire, etc, etc, but at some point the family is going to also want to cuddle up in front of a good movie, etc.

Any suggestions or feedback are always welcome. I have my PPT of the schematic and part numbers available if anybody wants. I'll let you know how it all works once we actually start travelling.

Lastly, I'd just like to thank the guys at Car Toys in Tulsa, OK. They definitely know their stuff and were a big help in building / installing the system really professionally.

Cheers,

Jay.

Just because you're environmentally friendly, doesn't mean you have to be boring...

One of the other things we did over the past couple of months was to design and configure the audio/video system for the vehicle. We're going to be spending a LOT of time in this truck, so we wanted to make sure that we had a way of taking all our tunes, and our toons with us. (two small kids!)

I started by thinking about where we would want to listen / watch our content, and then worked backwards from there. I knew we didn't want to carry around hundreds of CD's / DVD's with us, so a Hard-Drive media vault became obvious. Then, once we had that central storage concept, the question started to be about where should that be and how do we interconnect everything.

In the end, we came up with a pretty cool solution. Although we rarely talk electronics on ExPo, I thought it would be worth detailing for those interested.

We started with an InFill T3 in-dash PC. This takes the place of 2 DIN spots in the dash (same as my factory Ford radio) but manages to squeeze in a Windows XP PC, with a 40GB shock mounted hard drive and DVD drive. They are made in Korea and look like this:

Connected to this is a 1 Terrabyte (Yippee!) Western Digital USB Hard Drive mounted in foam in the centre console. I can't believe how cheap these are now. I got mine at Best Buy for about $230. We're in the process of ripping all our DVD's and MP3's to the drive. We'll never fill it...

The PC also has built in WiFi and we'll hook up my Cingular unlimited Data GSM card, and just get pre-paid SIM's as we travel around.

Then I found this amazing deal on HUGE 10.5" headrest monitors, with built in DVD/SD-card players from "GoodDeals18.com" - I was nervous ordering them as I'd never heard of the shop before, but they arrived exactly as promised and they're amazing. An F-650 is probably the only truck they wouldn't look huge in though!

The system is prewired to take inputs from our laptop on the Jotto Desk in the passenger seat if we want to play music from there too...

BUT... we're going to be spending most of our evenings back in the camper, so we also pre-wired the system to feed audio/video signals back to the LCD TV in the camper, and allow for a possible second one in the outdoor kitchen cabinet at some point in the future if we want to. These can be controlled by the RF Wireless keyboard and mouse from inside the camper.

The whole system then looks like this:

I'm a bit of a geek still at heart, so designing this part of the truck has been great fun. It's a lot of technology in an off-road rig, and we'll see how well it all holds up to the dust & vibrations on the trip - but I think it should be ok.

It is certainly a lot of complexity / money to invest in music / TV / Connectivity, but I justify by remembering that we're going to be spending 2 years in this thing with kids. We're certainly going to appreciate nature and sit around the campfire, etc, etc, but at some point the family is going to also want to cuddle up in front of a good movie, etc.

Any suggestions or feedback are always welcome. I have my PPT of the schematic and part numbers available if anybody wants. I'll let you know how it all works once we actually start travelling.

Lastly, I'd just like to thank the guys at Car Toys in Tulsa, OK. They definitely know their stuff and were a big help in building / installing the system really professionally.

Cheers,

Jay.