jscherb

Expedition Leader

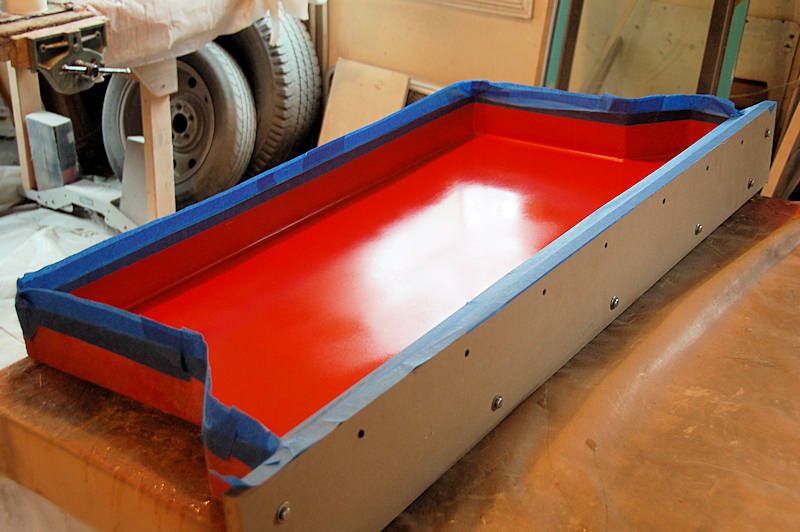

I've disassembled the tub so I can begin the paint prep and paint process. While I've got it apart I'll take a few photos...

Over the last week or so I've been finishing up the details of the frame, like the lighting and the rear stabilizer jacks, so now that the tub is off I can show the completed frame. The only thing not yet installed is the wiring harness. The harness is already done, and it just plugs into all of the lights that are installed, but I won't actually install it until after the frame is painted.

There are more photos of the bare frame in the main build thread at the Trailer Adventuring Forum:

http://tventuring.com/trailerforum/thread-119.html

Over the last week or so I've been finishing up the details of the frame, like the lighting and the rear stabilizer jacks, so now that the tub is off I can show the completed frame. The only thing not yet installed is the wiring harness. The harness is already done, and it just plugs into all of the lights that are installed, but I won't actually install it until after the frame is painted.

There are more photos of the bare frame in the main build thread at the Trailer Adventuring Forum:

http://tventuring.com/trailerforum/thread-119.html