TheJosh

Explorer

It is sooooo nice dealing with all new parts rather than trying to restore some rusty, dented old thing. And the fiberglass parts will never rust.

That's part of the fun in it for some like myself...

It is sooooo nice dealing with all new parts rather than trying to restore some rusty, dented old thing. And the fiberglass parts will never rust.

I like the length-wise split as it would allow me to open one side for my kitchen setup. In thinking more generally, I can see advantages to each, particularly with a tailgate - can't recall the details on the lid lip in terms of opening the tailgate with the length-wise split. One advantage of the length-wise is allowing for long objects to stay in place on one side while opening the other - like an OzTent or fishing poles.

Any chance you could mold as four pieces which could be bolted together as needed to create whatever split desired? Seems like even as two sections, we will need to think thru the hinge options depending on whether we bolt the two into one.

Really cool being a part of the design discussion!

Jeff, I am a loyal follower, but had an idea for consideration and didn't want to go back thru all the pages to see if it had been considered. If it has, I know it will be recorded in your brain files.

The idea is having the top split (either front to back or side to side) and hinged along the outer edge, instead of along the centerline split, so it can rotate open 180 degree, and the underside (which is now the 'top') be used as a surface for table, cooking, repairs, work surface, etc. Of course the loading of 'stuff' in or out of the trailer would have to be via the side that does not have the 'table' hanging open from it.

Taking this 1 step further, perhaps the 2 halves can be on slide mechanisms, and open by pulling on them (so they slide in the horizontal plane), rather than rotating them.

Another question: in your option to bolt together the crosswise split with a hinge at the side, could the fastening system be more flexible such that one could choose whether to open the entire lid or just one half, while out on the trail/during use?

.

At least for me, that would give me all the flexibility needed for long objects on top of the top, easy access to things inside, half-sized cargo rack over one section, etc. In my mind, I'm seeing some sort of track with a lip that bolts to one piece, creating a place for a water proofing seal of some kind as well as some structural support for the other half, but have no idea if such exists in a pre-fab form. If so, it might be stiff enough to not need any fasteners beyond the clamping/locking mechanisms.

Just a thought, and you've put many more hours of thought into these types of designs! In the end, my guess is that simply having a top of any kind available in the marketplace for all us old M416'ers will be welcomed enthusiastically!

Jeff, forgot to add that I personally like the flat front/rear vs. the bevel but that may just be me. I think it's fine either way.

I personally like the flat style, it just looks better to me.I could go either way on the ends, angled or flat, I haven't decided which style I like better yet.

I'm hoping there's enough input to the question here that a consensus develops to help with the final decision.

So you want to open it like this?

That poses a number of design and engineering challenges...

.

[...]

.

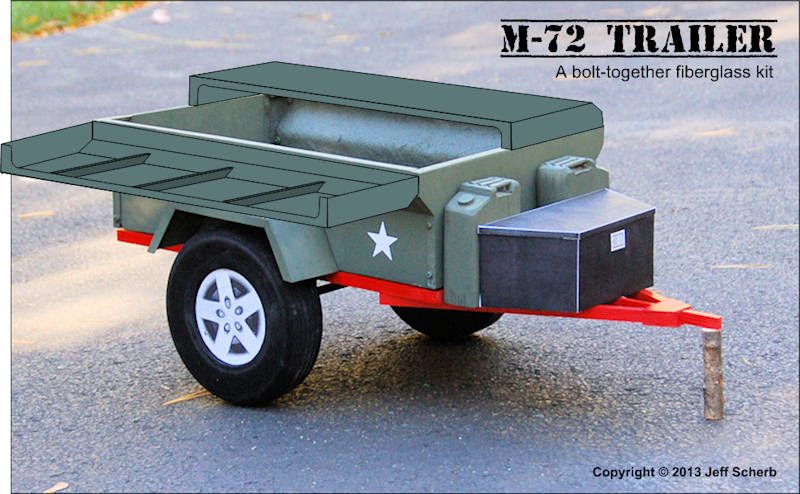

One of my key goals for this cover design is affordability, I'm trying to make the fiberglass parts and the hardware as simple as possible to keep costs down so that as many people as possible could afford a cover like this. I'm confident this design could be done pretty affordably, and since being two pieces it's small enough to ship UPS Ground, getting it delivered would also be far less expensive than the truck freight than a one piece cover would require.

I do like your ideas, it's just that some of them compete with my goal of designing something that could be as affordable as possible if it ever became a product on the marketLOL! Yea, I'm good at ideas that cost more money, are more complicated to build, and take more time - just look at what I've thrown into a $250 trailer over the last 15 years... but you got the idea!

In the end, I'm partial to the lengthwise split (left below):

.

View attachment 158174

.

but others should pitch in too.